Busbar Kg Calculation | Accurate Copper & Aluminum Busbar Weight Formula for Electrical Design

In electrical design and panel manufacturing, material estimation is not just about cost control. It also affects structural support, thermal performance, and installation planning. That is why busbar kg calculation is a routine task for engineers working on switchboards, distribution panels, and substation assemblies. A precise weight estimate helps in procurement, mechanical layout, transport planning, and compliance checks without unnecessary waste.

Table of Contents

Busbars are typically made of copper or aluminum and supplied in flat or rectangular sections. Their weight depends on cross-section dimensions, length, and material density. When handled properly, busbar kg calculation becomes a simple and reliable method for evaluating conductor mass before fabrication starts. This guide explains the concept in a practical way, using clear formulas, engineering logic, and tables that can be used directly during design work.

Find out more about contact resistance test acceptable value for busbar

Understanding the Importance of Busbar Weight Estimation

Electrical professionals often consider current carrying capacity and short circuit strength when sizing conductors. However, physical mass also matters. Heavy busbars influence mounting hardware, enclosure strength, and shipping cost. In large installations, even small deviations in busbar kg calculation can lead to notable financial impact.

Accurate estimation provides benefits such as:

- Correct structural support sizing

- Reliable transport and handling planning

- Precise cost evaluation for copper and aluminum stock

- Improved documentation for project bidding

- Better integration with panel layout and thermal design

Because busbars appear in LV and MV assemblies, renewable installations, and industrial distribution systems, mastering busbar kg calculation is an essential skill rather than an optional one.

Basic Concept Behind Busbar Kg Calculation

The process is based on a straightforward physical relationship. Weight equals volume multiplied by density. Volume is derived from cross sectional area and length, while density depends on conductor material.

Know more about IEC Standard for Busbar Clearance

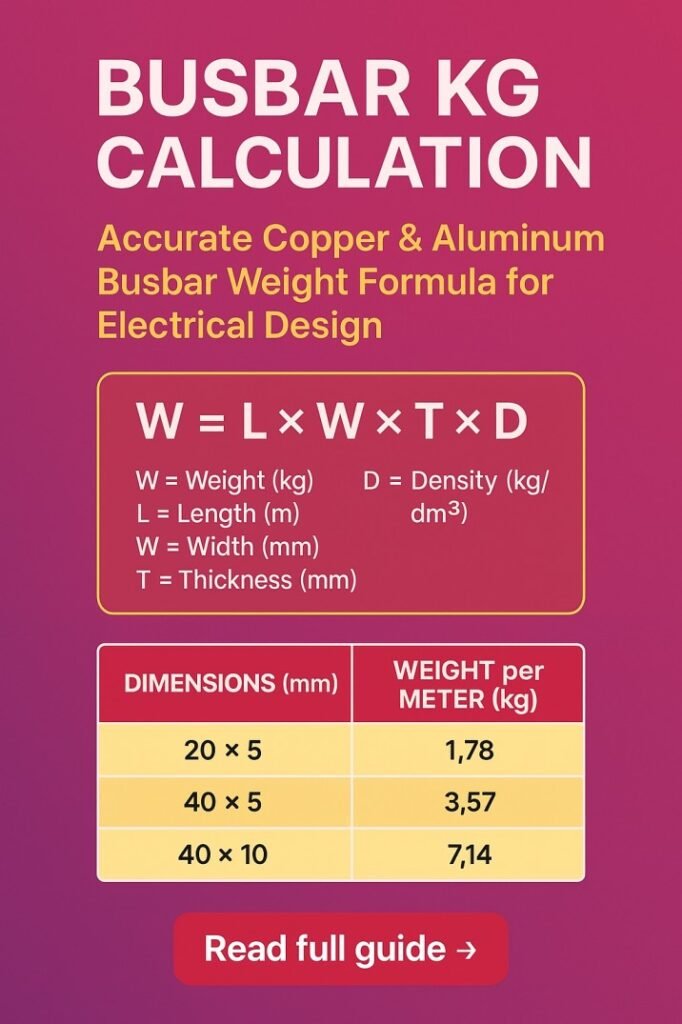

The general formula applied in busbar kg calculation is:

Weight (kg) = Length (m) × Width (mm) × Thickness (mm) × Density ÷ 1,000,000

The division factor converts cubic millimeters into cubic meters and ensures the result is expressed in kilograms.

Typical density values used in design calculations are shown below.

Table: Standard Density Values for Busbar Materials

| Material | Density (kg/m³) |

|---|---|

| Copper | 8,960 |

| Aluminum | 2,700 |

These values are commonly accepted for engineering estimation and procurement planning. Minor variations exist between grades, but they do not significantly affect routine busbar kg calculation.

Read in detail about iec 61439 busbar calculation

Step by Step Busbar Kg Calculation Procedure

Applying the formula becomes simple when broken into clear steps.

- Measure or select busbar width in millimeters

- Measure thickness in millimeters

- Determine total conductor length in meters

- Choose density based on material type

- Insert values into the formula

This method ensures consistency when performing busbar kg calculation across multiple panel sections or phases.

Consider a copper bar sized 50 mm by 10 mm and length of 3 meters.

Weight = 3 × 50 × 10 × 8960 ÷ 1,000,000

Weight = 13.44 kg

The same dimensions using aluminum give:

Weight = 3 × 50 × 10 × 2700 ÷ 1,000,000

Weight = 4.05 kg

This comparison highlights how material choice influences final mass and structural requirements.

Get complete information about iec standard for busbar sizing

Ready Reference Table for Copper Busbar Kg Calculation

For faster estimation during design review, engineers often rely on precomputed values. The table below lists approximate weight per meter for common copper sections derived through busbar kg calculation.

Table: Copper Busbar Weight per Meter

| Size (mm) | Weight kg/m |

|---|---|

| 25 × 3 | 0.67 |

| 25 × 5 | 1.12 |

| 32 × 6 | 1.72 |

| 40 × 5 | 1.79 |

| 50 × 6 | 2.69 |

| 50 × 10 | 4.48 |

| 75 × 10 | 6.72 |

| 100 × 10 | 8.96 |

Values may vary slightly due to manufacturing tolerance, yet they remain practical for routine busbar kg calculation in switchgear projects.

Find out more about iec 61439 busbar clearance

Ready Reference Table for Aluminum Busbar Kg Calculation

Aluminum offers lighter weight and lower cost, which is why many distribution assemblies prefer it. The following table applies the same busbar kg calculation logic.

Table: Aluminum Busbar Weight per Meter

| Size (mm) | Weight kg/m |

|---|---|

| 25 × 3 | 0.20 |

| 25 × 5 | 0.34 |

| 32 × 6 | 0.52 |

| 40 × 5 | 0.54 |

| 50 × 6 | 0.81 |

| 50 × 10 | 1.35 |

| 75 × 10 | 2.03 |

| 100 × 10 | 2.70 |

These quick values save time when performing repetitive busbar kg calculation during proposal preparation or layout verification.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Factors Influencing Calculation Accuracy

While the formula is simple, real projects include practical considerations that affect final weight. Engineers should account for the following aspects when performing busbar kg calculation.

- Surface plating such as tin or silver adds small mass increments.

- Bends and fabrication trimming slightly reduce net usable length.

- Temperature expansion may change dimensional tolerance.

- Manufacturing standards define permissible size variation.

- Joint hardware and insulation supports add assembly weight.

Including contingency margins improves the reliability of busbar kg calculation and avoids underestimation in procurement schedules.

Integration with Electrical Design Workflow

Busbar kg calculation is rarely performed in isolation. It connects with other engineering tasks including thermal studies, voltage drop checks, and short circuit withstand verification. For example, once conductor size is finalized from current rating calculations, weight estimation supports mechanical layout validation.

Find out more about High Impedance Busbar Protection Explained with Example Calculations

In renewable plants, distribution skids, or industrial MCC systems, busbar kg calculation also supports lifting arrangement planning. Accurate documentation enables logistics teams to determine transport load limits and safe handling methods.

Engineers often combine spreadsheet tools with CAD layouts so that dimension changes instantly update weight totals. This integrated approach enhances productivity and reduces revision time.

Practical Example Covering a Three Phase Arrangement

Assume a panel uses three copper phase bars sized 75 mm by 10 mm, each 2.5 meters long, plus a neutral bar of identical size.

Single bar weight per meter from earlier reference

6.72 kg/m

Weight per bar

6.72 × 2.5 = 16.8 kg

Total bars

4

Total weight

16.8 × 4 = 67.2 kg

This straightforward application of busbar kg calculation shows how quickly overall conductor mass can be estimated for enclosure design and mounting support selection.

Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

Best Practices for Reliable Estimation

Maintaining accuracy and consistency requires disciplined methods during daily engineering work. Recommended practices include:

- Always verify dimensions from approved drawings

- Use standardized density constants

- Maintain updated reference tables

- Apply rounding carefully in reports

- Cross check manual and spreadsheet results

Following these steps ensures busbar kg calculation remains dependable across complex electrical projects. Find all about Busbar Bending Calculation

Conclusion

Material estimation is a core part of professional electrical engineering, and busbar kg calculation plays a central role in that process. By understanding the relationship between dimensions, length, and material density, engineers can quickly determine conductor mass with confidence. This knowledge improves budgeting, structural planning, and installation logistics while supporting better project outcomes.

Whether working with copper in high current assemblies or aluminum in cost sensitive distribution systems, mastering busbar kg calculation provides a practical advantage in daily design tasks. Using the formulas, tables, and examples presented here allows accurate evaluation without complexity, making weight estimation a smooth and reliable part of modern electrical design workflow.

Find all about Busbar Size Chart in mm

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BusbarKgCalculation, #BusbarWeightCalculation, #ElectricalDesign, #PowerSystemEngineering, #CopperBusbar, #ElectricalCalculations, #SwitchgearDesign, #EngineeringTools, #ElectricalEngineers, #PowerDistribution