IEC Standard for Motor Noise Level Explained: Limits, Testing Methods & Best Compliance Guide

Electric motors are no longer evaluated only on efficiency and reliability. In modern industrial environments, noise emission has become a critical performance parameter. Excessive motor noise affects workplace safety, regulatory compliance, and even customer perception. This is where the iec standard for motor noise level plays a decisive role. It provides a globally accepted framework to measure, limit, and control noise generated by electric motors across industries.

Table of Contents

This article explains the iec standard for motor noise level in a practical and engineering-focused way. You will understand applicable limits, standardized testing methods, and how manufacturers and users ensure compliance in real installations.

Why motor noise standards matter in modern industry

Industrial noise is not just an annoyance. Prolonged exposure can cause hearing damage, reduce concentration, and increase fatigue among workers. Many countries now enforce strict occupational noise regulations aligned with international standards. The iec standard for motor noise level helps manufacturers design quieter machines while giving end users confidence that motors meet acceptable acoustic limits.

Noise control is also important in sectors such as HVAC, food processing, hospitals, and commercial buildings. In these applications, acoustic comfort directly affects user experience and system acceptance.

Find all about IEC Standard for Relay Testing: Best Guide

Overview of IEC standards related to motor noise

The iec standard for motor noise level is not a single document but a set of coordinated standards. The most relevant ones include IEC 60034-9, which specifies noise limits, and IEC 60034-14, which addresses vibration and its relationship with noise. Together, these standards define how noise is measured, reported, and compared.

IEC standards focus on airborne sound power level rather than subjective sound pressure alone. This ensures consistent results regardless of test environment. By following the iec standard for motor noise level, manufacturers across different regions can benchmark products using the same criteria.

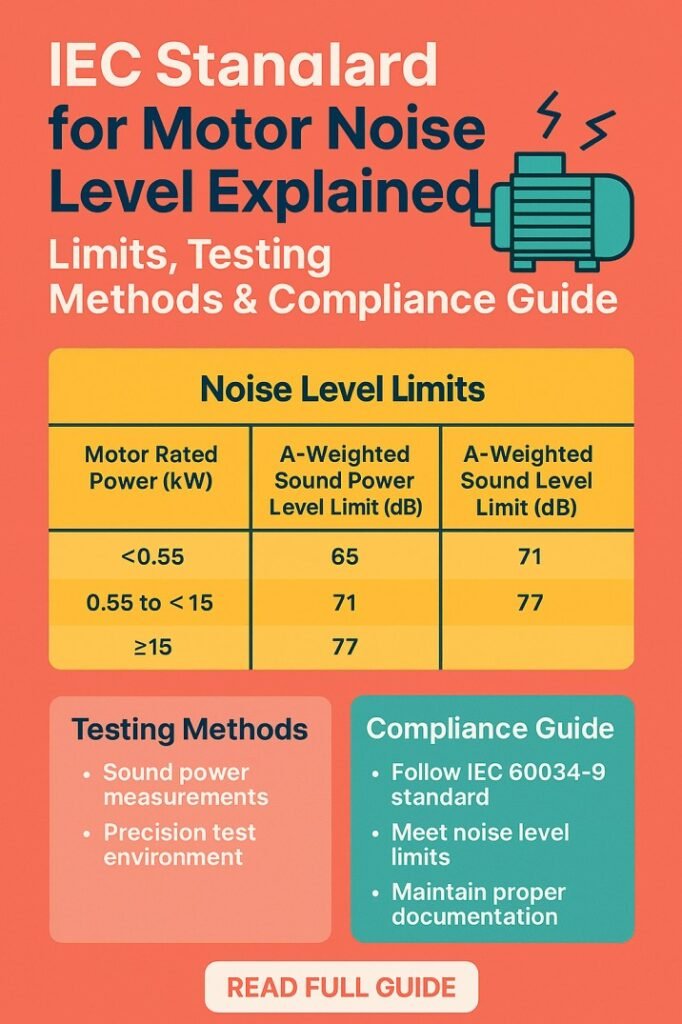

Key noise limits defined by IEC standards

Noise limits depend on motor type, power rating, speed, and enclosure. IEC standards classify motors into ranges and specify maximum permissible sound power levels in decibels.

The table below shows typical reference limits based on IEC 60034-9 for standard induction motors.

| Rated Output Power | Number of Poles | Typical Noise Limit dB(A) |

|---|---|---|

| Up to 1 kW | 2 or 4 | 72 |

| 1 kW to 10 kW | 2 or 4 | 75 |

| 10 kW to 100 kW | 2 or 4 | 80 |

| Above 100 kW | 2 or 4 | 85 |

| Any rating | 6 or more | Lower by 3 to 5 dB |

These values are indicative and vary with enclosure type such as open drip proof, totally enclosed fan cooled, or explosion-proof designs. The iec standard for motor noise level ensures these limits are applied consistently across manufacturers.

Find all about BS 7671 Wiring Regulations: Expert Guide to Compliance, Safety, and Practical Applications

How motor noise is measured under IEC standards

Measurement is a critical part of compliance. The iec standard for motor noise level specifies controlled test conditions to avoid misleading results. Motors are tested at rated voltage, frequency, and load unless otherwise stated.

Noise is measured as sound power level using standardized acoustic environments. These include semi-anechoic chambers or reverberation rooms. Background noise must be sufficiently low to avoid interference.

The following table summarizes key test conditions.

| Parameter | IEC Requirement |

|---|---|

| Operating condition | Rated load and rated speed |

| Measurement distance | Defined microphone positions |

| Environment | Semi-anechoic or reverberant room |

| Quantity measured | Sound power level dB(A) |

| Instrument accuracy | Class 1 sound level meters |

By standardizing the test setup, the iec standard for motor noise level ensures repeatable and comparable results worldwide.

Know all about ieee and iec standards

Difference between sound pressure and sound power

Many engineers confuse sound pressure level with sound power level. Sound pressure depends on distance and environment, while sound power is an inherent property of the motor. IEC standards emphasize sound power because it allows fair comparison between products.

When a motor datasheet states compliance with the iec standard for motor noise level, it usually refers to sound power values measured under defined conditions. This distinction is essential when selecting motors for noise-sensitive installations.

Common sources of motor noise

Understanding noise sources helps in both design and troubleshooting. The iec standard for motor noise level does not control design directly but influences it through limits.

Typical noise sources include electromagnetic forces in the air gap, mechanical vibration from bearings, cooling fan turbulence, and structural resonance of the frame. Poor alignment or unbalanced rotors can increase noise beyond permissible limits even if the motor design is compliant.

Know more about Transformer Oil Testing: 9 Important Tests for Healthiness

Relationship between vibration and noise

Noise and vibration are closely linked. IEC 60034-14 addresses vibration severity, which indirectly affects acoustic performance. Excessive vibration often results in higher noise levels and faster mechanical wear.

Manufacturers aiming to meet the iec standard for motor noise level must control vibration through precision balancing, quality bearings, and rigid construction. End users should also ensure proper installation to avoid resonance with foundations or connected equipment.

Compliance requirements for manufacturers

For manufacturers, compliance with the iec standard for motor noise level is part of product certification and quality assurance. Noise testing is typically done during type testing rather than routine production tests.

Manufacturers must document test conditions, measurement uncertainty, and declared noise values. These values appear on motor nameplates or technical catalogs. Transparent reporting builds trust with customers and regulators.

Responsibilities of end users and system designers

Compliance does not end at the factory. End users and system designers play a role in maintaining acceptable noise levels. Improper mounting, inadequate ventilation, or operation outside rated conditions can increase noise.

When selecting motors, engineers should compare declared noise values and consider application-specific limits. The iec standard for motor noise level provides a baseline, but local regulations or project specifications may require stricter limits.

Know more about IEC Standard for MV Cable Testing: Complete Acceptance, Routine & Type Test Guide

Practical compliance checklist

The following table provides a simple compliance checklist for engineers and facility managers.

| Step | Action Required |

|---|---|

| Motor selection | Verify declared IEC noise values |

| Installation | Ensure rigid base and proper alignment |

| Operation | Run within rated load and speed |

| Maintenance | Monitor bearings and cooling fans |

| Verification | Measure noise if workplace limits are critical |

Using this approach helps ensure ongoing compliance with the iec standard for motor noise level throughout the motor’s service life.

Future trends in motor noise regulation

As industries move toward energy-efficient and high-speed motor designs, noise control is gaining more attention. Variable frequency drives, while efficient, can introduce additional acoustic components. IEC standards continue to evolve to address these challenges.

The iec standard for motor noise level is expected to become more integrated with environmental and occupational health regulations. Engineers who understand these standards today will be better prepared for future compliance demands.

Know more about IEC Standard for Insulation Resistance Test – Procedures, Limits & Best Practices Explained

Final thoughts

Motor noise is no longer a secondary consideration. It directly affects safety, comfort, and regulatory approval. The iec standard for motor noise level provides a clear and internationally recognized framework to manage this aspect of motor performance.

By understanding noise limits, testing methods, and compliance responsibilities, engineers can select and operate motors with confidence. Whether you are a manufacturer, consultant, or maintenance professional, applying the iec standard for motor noise level correctly ensures quieter, safer, and more reliable electrical systems. Know more about IEC Standard for Earthing System

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard,#MotorNoiseLevel,#ElectricMotorStandards,#IndustrialMotorNoise,#IECRegulations,#MotorAcoustics,#ElectricalEngineering,#NoiseMeasurement,#IEC60034,#MotorTesting