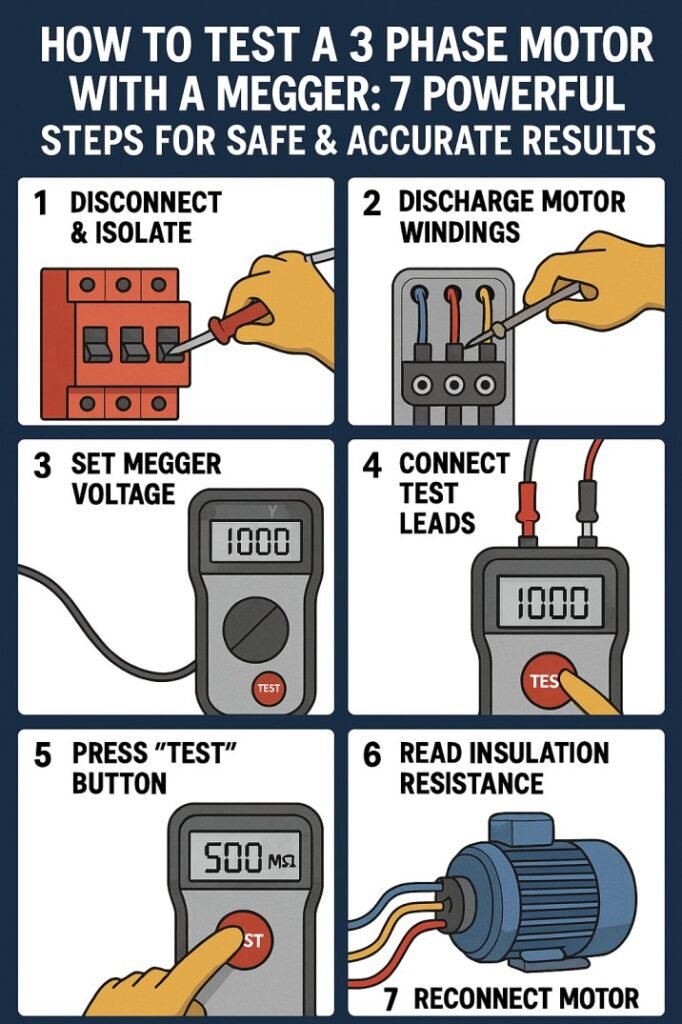

How to Test a 3 Phase Motor With a Megger: 7 Powerful Steps for Safe & Accurate Results

Understanding how to test a 3 phase motor with a megger is essential for anyone responsible for electrical maintenance, industrial equipment, and motor reliability. A proper insulation resistance test helps you detect early faults, prevent equipment breakdowns, and maintain a safer working environment. The process is simple when you follow the right steps, use the correct insulation tester, and understand what reading indicates a healthy motor.

Table of Contents

This guide explains how to test a 3 phase motor with a megger in clear, easy-to-read steps. Each step focuses on accuracy, safety, and practical knowledge that you can apply immediately.

Why Insulation Resistance Testing Matters

A 3 phase motor works under continuous stress from heat, dust, moisture, and electrical load. Over time, insulation around the windings can deteriorate. When that happens, leakage current increases. This leads to short circuits, motor failure, and shutdowns.

Know more about IEC Standards for Transformer Testing – Complete Guide to IEC 60076 and Testing Procedures

Knowing how to test a 3 phase motor with a megger helps you check the insulation condition before problems occur. It also helps in preventive maintenance, troubleshooting, and planning motor replacement.

Before You Start the Test

Before learning how to test a 3 phase motor with a megger, prepare the tools and the environment. This ensures the readings are accurate and eliminates safety risks.

Pre-Test Requirements

| Requirement | Description |

|---|---|

| Power OFF | The motor must be disconnected completely |

| Lockout/Tagout | Prevents accidental energizing |

| Discharge capacitors | Ensures no stored energy remains |

| Clean terminals | Dirt or moisture affects readings |

| Correct megger range | Typically 500V–1000V for industrial motors |

Once the motor is isolated and prepared, you can begin the insulation resistance test.

Step 1: Identify All Motor Terminals

The first step in how to test a 3 phase motor with a megger is identifying the terminals properly. A 3 phase motor has three main windings: U1-U2, V1-V2, and W1-W2. These might also appear as R-Y-B or L1-L2-L3 depending on your region.

Make sure the terminal box is clean and free of moisture. Dirt or oil can impact the insulation test and produce low resistance readings.

Know more about IEC Standard for XLPE Cables – Complete Guide to IEC 60502 and Electrical Cable Specifications

Step 2: Disconnect All External Connections

Remove all cables connected to the motor terminals. This includes supply cables, control wiring, and earth bonding wires. You must isolate the motor windings so the insulation tester measures only the motor, not the entire circuit.

This step ensures accurate readings and prevents misleading results during the process of learning how to test a 3 phase motor with a megger.

Step 3: Perform Phase-to-Phase Insulation Testing

Next, you will test the insulation between the windings. This checks whether the insulation separating the phases is healthy.

How to Test Phase to Phase

- Connect the megger’s positive lead to the U phase.

- Connect the negative lead to the V phase.

- Apply the test voltage.

- Record the reading.

- Repeat for all combinations.

| Test Points | What It Checks | Expected Reading |

|---|---|---|

| U to V | Insulation between two phases | Usually above 1 MΩ |

| V to W | Insulation between two phases | Above 1 MΩ |

| U to W | Insulation between two phases | Above 1 MΩ |

Higher values indicate better insulation. If the value is low, the motor needs drying, cleaning, or further inspection.

Know more about IEC Standard for Relay Coordination – Complete Guide to Protection and Coordination Studies

Step 4: Perform Phase-to-Earth Insulation Testing

Testing phase-to-earth insulation is a crucial part of how to test a 3 phase motor with a megger. It detects breakdowns between windings and the motor frame. This is one of the most common insulation faults.

Test Steps

- Connect the megger’s positive lead to the motor phase.

- Connect the negative lead to the motor body (earth).

- Apply voltage.

- Record the value.

- Repeat for all phases.

| Phase Tested | Minimum Acceptable IR Value | Condition |

|---|---|---|

| U to Earth | 1 MΩ minimum | Good above 5 MΩ |

| V to Earth | 1 MΩ minimum | Good above 5 MΩ |

| W to Earth | 1 MΩ minimum | Good above 5 MΩ |

If any phase shows much lower resistance compared to others, the motor insulation may be damaged.

Step 5: Compare Results With Standard IR Values

After completing all test readings, compare them with insulation resistance standards. This is a critical part of understanding how to test a 3 phase motor with a megger correctly. Standards help identify whether the motor is safe to run.

Know more about IEC Standard for Vibration Testing – IEC 60068 Explained with Procedures and Requirements

IR Value Guidelines

| Insulation Condition | Resistance Value | Motor Condition |

|---|---|---|

| Excellent | Above 100 MΩ | Safe to operate |

| Good | 10–100 MΩ | Acceptable |

| Fair | 1–10 MΩ | Monitor regularly |

| Poor | Below 1 MΩ | Do not operate |

Environmental factors like humidity, temperature, and dust affect IR values. Always consider these factors before making a final judgment.

Step 6: Perform a Polarization Index Test

A Polarization Index (PI) test gives deeper insight into insulation quality over time. This is optional but highly useful when evaluating how to test a 3 phase motor with a megger in professional settings.

How a PI Test Works

- Apply megger voltage for 10 minutes.

- Record resistance at 1 minute (R1).

- Record resistance at 10 minutes (R10).

- PI = R10 ÷ R1.

PI Value Interpretation

| PI Value | Condition |

|---|---|

| Above 2.0 | Excellent insulation |

| 1.5 to 2.0 | Good insulation |

| 1.0 to 1.5 | Fair insulation |

| Below 1.0 | Failing insulation |

A low PI value means moisture or insulation breakdown.

Know more about IEC Standard for Vacuum Circuit Breaker – IEC 62271 Guidelines, Ratings & Testing Explained

Step 7: Restore Connections and Document Results

The final step in how to test a 3 phase motor with a megger is restoring all connections correctly and documenting your readings. Proper documentation helps in future maintenance and prevents repeated testing.

What to Record

| Information | Why It Matters |

|---|---|

| Test voltage used | Confirms correct rating |

| Phase-to-phase readings | Detect insulation imbalance |

| Phase-to-earth readings | Ensures safe operation |

| Temperature during test | Affects resistance values |

| Date and technician name | Maintenance record |

Once documentation is complete, reconnect cables, remove lockout tags, and return the motor to service only if readings are acceptable.

Tips for More Accurate Megger Testing

Here are simple tips to improve the accuracy of your insulation resistance testing.

- Always test in a dry environment.

- Clean dust and moisture before testing.

- Allow the motor to cool before taking readings.

- Use the correct megger voltage recommended by the manufacturer.

- Compare readings with past maintenance records.

These practices support long-term motor health and enhance the quality of evaluating how to test a 3 phase motor with a megger.

Final Thoughts

Learning how to test a 3 phase motor with a megger is one of the most valuable skills in electrical maintenance. It protects equipment, prevents failures, and ensures safe operation. The seven steps in this guide provide a complete process from preparation to documentation. By following these steps, you can accurately measure insulation resistance and keep your motor in optimal condition.

Know more about IEC Standard for Megger Test: Insulation Resistance Testing According to IEC Guidelines

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#howtotesta3phasemotorwithamegger, #motorwindingtest, #meggertesting, #motorinspection, #electricaltesting, #motormaintenance, #industrialmaintenance, #motorrepair, #electricalsafety, #powerengineering