Minimum Earthing Conductor Size: Best Guide

Minimum Earthing Conductor Size

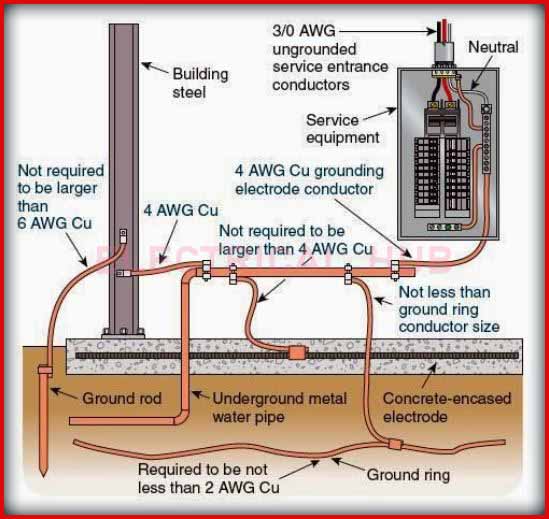

Earthing conductors play a crucial role in electrical safety by providing a path for fault currents to ground, thus preventing electric shock and equipment damage. Understanding the minimum earthing conductor size is essential for compliance with safety standards and ensuring effective grounding systems. This article will delve into the technical aspects, regulations, and calculations involved in determining the minimum size of earthing conductors.

Table of Contents

Importance of Earthing Conductors

Earthing conductors serve several vital functions:

- Safety: They protect individuals from electric shock by directing fault currents safely to the ground.

- Equipment Protection: They safeguard electrical equipment from damage due to overcurrent conditions.

- System Stability: A well-designed earthing system minimizes voltage fluctuations and enhances system reliability.

Regulations Governing Earthing Conductor Size

The sizing of earthing conductors is governed by various international and national standards, including:

- IEC 60364: This standard outlines the requirements for electrical installations, including earthing.

- AS/NZS 3000: This Australian/New Zealand standard provides guidelines for electrical installations and includes specifications for earthing conductor sizing.

- BS 7671: The IET Wiring Regulations detail requirements for electrical installations in the UK.

Key Regulations

Minimum Cross-Sectional Area:

- For copper conductors, the minimum size is typically 6 mm².

- For aluminum conductors, the minimum size is often set at 10 mm².

Sizing Based on Active Conductors:

- The size of the earthing conductor may be determined based on the cross-sectional area of the largest active conductor in the circuit.

Short-Circuit Rating:

- The earthing conductor must have an adequate short-circuit rating for the prospective earth fault current and fault clearing time.

Note: Use our online electrical load calculator for electrical load calculation here. You can also use voltage drop calculator for voltage drop calculation and for cable selection in any single and three phase circuit here. Further explore our online electrical calculators to design your electrical systems in an efficient way.

Methods for Determining Minimum Earthing Conductor Size

The sizing of earthing conductors can be approached using two primary methods:

Simplified Method

This method relates the size of the protective earthing (PE) conductor to that of the phase conductors. The following table summarizes this approach:

| Phase Conductor Size (mm²) | Minimum PE Conductor Size (Copper mm²) | Minimum PE Conductor Size (Aluminum mm²) |

|---|---|---|

| ≤ 16 | Same as phase conductor | Same as phase conductor |

| 16 < S ≤ 25 | 16 | 16 |

| 25 < S ≤ 35 | 25 | 25 |

| 35 < S ≤ 50 | S/2 | S/2 |

| > 50 | S/2 | S/2 |

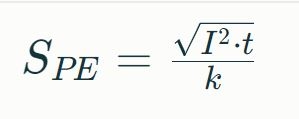

Adiabatic Method

This method calculates the required cross-sectional area based on fault current and duration, using the formula:

Where:

- I = Maximum earth fault current (A)

- t = Duration of fault current (s)

- k = Material constant depending on conductor material

Factors Influencing Minimum Earthing Conductor Size

Several factors must be considered when determining the minimum earthing conductor size:

Fault Current Rating:

- The expected maximum fault current must be calculated to ensure that the conductor can handle it without overheating.

Environmental Conditions:

- Conductors exposed to harsh conditions (e.g., moisture, corrosion) may require larger sizes or additional protection.

Installation Method:

- Buried conductors may require larger sizes due to soil resistivity and potential deterioration over time.

Mechanical Strength:

- The conductor must withstand mechanical stresses during installation and operation.

Technical Insights and Calculations

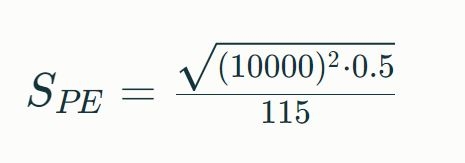

Example Calculation

Assuming a fault current of I=10kA lasting for t=0.5s, using copper with a material constant k=115:

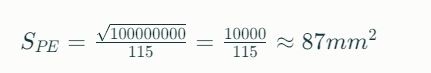

Calculating this gives:

Thus, a minimum earthing conductor size of approximately 87 mm² would be required under these conditions.

Table: Minimum Earthing Conductor Sizes Based on Standards

| Standard | Minimum Copper Size (mm²) | Minimum Aluminum Size (mm²) |

|---|---|---|

| IEC 60364 | 6 | 10 |

| AS/NZS 3000 | 6 | 10 |

| BS 7671 | 2.5 | N/A |

Related Technical Questions & Answers

Q1: What happens if the earthing conductor size is too small?

A1: A small earthing conductor may not safely carry fault currents, leading to overheating, potential fire hazards, or failure to trip protective devices effectively.

Q2: Can I use a PEN conductor as an earthing conductor?

A2: Yes, but it must meet specific cross-sectional area requirements and should not be used in flexible cables.

Q3: How often should I test my earthing system?

A3: Regular testing is recommended at least annually or after any significant alterations or repairs to ensure continued effectiveness.

Conclusion

Understanding the minimum earthing conductor size is essential for ensuring electrical safety and compliance with regulations. By considering factors such as fault current ratings, environmental conditions, and installation methods, one can determine the appropriate size for effective grounding systems. Following established standards like IEC, AS/NZS, and BS ensures that installations are safe and reliable, protecting both individuals and equipment from electrical hazards.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

EarthingConductor, #ElectricalSafety, #GroundingSystem, #ElectricalEngineering, #EarthingStandards, #ConductorSize, #GroundingRequirements, #EarthResistance, #EarthingSystem, #ElectricalInstallation, #PowerDistribution, #ElectricalWiring, #ElectricalProtection, #CableSizing, #GroundingConductor