Throttle Position Sensor Working & Types: Best Guide

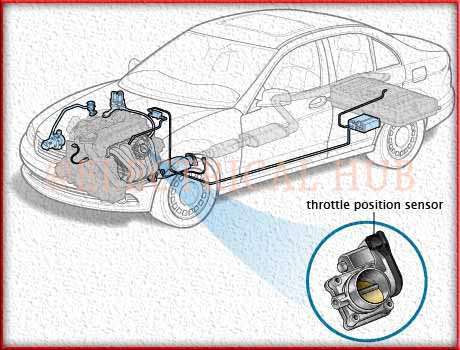

The throttle position sensor, often referred to as the TPS sensor or Throttle Valve Position sensor, serves as a vital component within the electronic throttle control system. Seamlessly integrated into the throttle body, this sensor meticulously monitors the angle of your vehicle’s throttle.

Table of Contents

Working of Throttle Position Sensor

The throttle position sensor continuously observes the extent to which the throttle valve, also known as the blade, is open. The sensor’s function hinges on the depression level of the accelerator pedal, directly influencing the volume of air entering the engine’s intake manifold.

As the throttle widens, facilitating increased airflow, or nears closure, restricting air intake, the sensor transmits this positional data to the engine control module. This crucial information serves as a determinant for the computer’s adjustments, dictating both fuel injection quantity and spark timing.

Physically situated on the throttle body housing, the throttle position sensor’s malfunction can prompt a multitude of issues, from triggering the “check engine” light to erratic engine behavior, including rough idling, surges, hesitations, or complete stalls. This malfunction disrupts the engine control module’s ability to accurately regulate fuel mixtures or ignition timings due to the lack of precise throttle position data.

Role of Throttle Position Sensor

Now, let’s explore the technical intricacies of the throttle’s role in your vehicle’s mechanics. Positioned between the air cleaner and the engine’s intake manifold, the throttle body assumes a pivotal function in managing the engine’s power output. Housing a butterfly valve, or the throttle opening, this component orchestrates the volume of air admitted into the engine.

Linked to the gas pedal by a cable wire mechanism, the throttle body’s throttle shaft movement is contingent upon the driver’s manipulation of the gas pedal. The throttle position sensor, acting as a potentiometer, varies its resistance based on the angle of the throttle valve. At wide-open throttle (WOT), the sensor emits an output voltage of approximately 4.5 volts to the vehicle’s Engine Control Unit (ECU).

Upon depression of the accelerator pedal, the throttle sensor promptly relays this action to the ECU or ECM, concurrently signaling the Mass Air Flow Sensor to detect increased air intake. Subsequently, the ECU assumes control over the air-fuel ratio, determining optimal spark plug ignition timings.

Buy Throttle position sensor Adjustment Tool

[wptb id=11347]Throttle Position Sensor Faulty Codes

In certain instances, the throttle position sensor adopts the Hall Effect methodology, leveraging magnetic fields that adjust as the throttle undergoes opening and closing movements. The throttle position sensor transmits a low voltage signal, falling below the minimum reference voltage threshold of 4.5 volts.

The Engine Control Unit or Engine Control Module is likely to trigger trouble codes, namely P0120, P0121, P0122, P0123, or P0124, culminating in the activation of the check engine light. Rectification of such issues typically necessitates the use of an OBD II scan tool for diagnostic purposes by a qualified mechanic.

Tracing Throttle Position Sensor Faulty

Recognizing the indications of a faulty TPS sensor is important. Here are five key symptoms that warrant attention:

Insufficient Power: Incorrect throttle valve position reporting may result in excessive air intake relative to the compensated fuel mixture, leading to diminished engine power. Conversely, malfunctioning TPS can cause unintended vehicle surges, compromising overall engine performance.

Acceleration Issues: Reduced engine power due to a faulty throttle position sensor often manifests as difficulties in acceleration, resulting in uneven acceleration or an inability to accelerate beyond a certain threshold. This issue can adversely impact engine longevity and fuel efficiency.

Increased Fuel Consumption: A contaminated throttle sensor might relay inaccurate readings to the ECU, prompting excessive fuel consumption and severely diminishing the vehicle’s fuel efficiency. This scenario parallels the hindrance caused by debris accumulation around the throttle opening, impeding airflow and causing unburned fuel to traverse the exhaust system.

Irregular Idle: Inaccurate reporting of throttle plate operations by the TPS manifests as poor or erratic idling, including instances of engine stalling, low idle post-start, or stalling upon accelerator pedal actuation. Accumulated dirt around the throttle area further exacerbates fluctuations in idle speed.

Illuminated Check Engine Light: As the primary monitor of the throttle plate, any discrepancy in the TPS connector or failure in accurately monitoring throttle operations triggers the Check Engine Light, signaling compromised engine performance.

Addressing these symptoms promptly is crucial, prompting the question: Can one replace a car’s throttle position sensor independently?

While feasible, replacing a throttle position sensor is best entrusted to a qualified mechanic due to the potential complexities involved, which might necessitate supplementary repairs such as fuel tank inspection or replacement. The placement complexities associated with certain vehicle models further underscore the importance of seeking professional assistance upon detecting a faulty throttle position sensor.

Neglecting to address a malfunctioning TPS sensor can engender detrimental repercussions. Prolonged usage of a defective sensor may induce engine wear and an array of noticeable problems, including erratic idling, unintended acceleration, difficulties in gear shifting, and compromised functionalities such as air conditioning, ignition timing, and fuel efficiency.

Contemplating the financial aspect of resolving this issue prompts consideration of the associated costs:

The cost of replacing a throttle position sensor typically ranges between $250 and $500, contingent upon various factors including the severity of the issue, vehicle model, geographical location, labor charges imposed by the mechanic, and the cost of requisite car parts. These costs serve as estimates and may vary accordingly.

Types of Throttle Position Sensor

Throttle position sensors (TPS) come in different types, each with its own way of tracking and relaying throttle movement to your car’s engine control system.

Sliding Resistance Position Sensor: This type, also known as a linear output TPS, uses a three-wire system. It has two power terminals and a third one connected to a sliding contact. As you step on the gas, this contact slides along a resistor, changing its potential and translating the throttle’s position into a voltage value. This linear voltage helps the Engine Control Unit (ECU) precisely gauge how far the throttle is open, allowing the ECU to adjust engine performance accordingly.

Idle Switching Position Sensor: Idle switching sensors, as the name suggests, detect when the throttle is at idle. They’re often used to signal the ECU that the throttle is closed, which can influence things like fuel cut-off or idle adjustments.

Sliding Resistance Integration Position Sensor: This sensor type is about combining the sliding resistance mechanism with other sensors or systems to provide more comprehensive throttle position data to the ECU.

Double Slide Resistance Sensors: These sensors use a dual slide resistance setup to monitor throttle movement. By employing two sliding contacts, they provide redundancy and a backup in case one fails.

Linear Double Hall Sensors: A more advanced type, these sensors utilize Hall elements and magnets to detect changes in magnetic flux caused by throttle movement. These changes are converted into electrical signals that represent the throttle’s position and are then sent to the ECU for processing.

Different cars may use different types of TPS. For instance, some Toyota models like the Camry use Hall sensors, while others like Nissan’s Scorpio or General Excelle might use slide resistance sensors. Each type has its strengths and specific applications, contributing to the precise control and performance optimization of the engine.

Throttle position sensor resistance test

Testing the resistance of a throttle position sensor (TPS) involves using a multimeter to measure the sensor’s internal resistance. Here’s how you can do it:

Disconnect the Sensor: Start by disconnecting the electrical connector from the TPS. This ensures you’re testing only the sensor’s resistance, not the entire circuit.

Set the Multimeter: Set your multimeter to measure resistance (ohms) and select an appropriate range if it’s not an auto-ranging multimeter.

Probe the Terminals: With the multimeter leads, touch the probes to the appropriate terminals on the disconnected TPS. Check the service manual or wiring diagram to identify the specific terminals to test. Typically, you’ll be measuring between the signal terminal and the ground terminal.

Read the Resistance: The multimeter will display the resistance reading. Compare this reading to the manufacturer’s specifications. Usually, the resistance should change smoothly and consistently as you manually move the throttle. Ensure the resistance falls within the recommended range as the throttle is opened and closed.

Check for Smooth Variation: Slowly move the throttle and observe the resistance reading on the multimeter. It should change gradually and steadily without sudden jumps or drops. Any irregularities might indicate a faulty sensor.

Repeat the Test: Perform this test a few times at different throttle positions to ensure consistency in the resistance values.

Interpret the Results: If the resistance values are significantly outside the specified range, or if there are erratic changes in resistance while moving the throttle, it could indicate a defective TPS that might need replacement.

This test helps determine if the TPS is functioning within the expected resistance parameters and providing consistent readings as the throttle position changes. Always consult the vehicle’s service manual or technical specifications to ensure correct testing procedures and interpretation of the resistance readings for your specific TPS model.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

- OBD2 Pinout

- LR44 Battery

- CR123 Battery

- Lithium Ion Batteries

- Methods of Electrical Earthing

- Electrical Earthing Important Types

- Plant Factor, Plant Capacity Factor, and Load Factor

- Buck Converter Interview Questions

- DC DC Converter Interview Questions

- Transformer Electrical Interview

- Top 30 Op Amp Interview Questions

- Power Electronics Interview Questions

very interesting points you have observed, thanks for putting up.

Excellent post. I was checking continuously this blog and I’m inspired! Very helpful info specially the ultimate section 🙂 I care for such information much. I was seeking this particular information for a long time. Thank you and good luck.