3 Phase Electric Motor Troubleshooting – Proven Fault Diagnosis & Repair Guide

3 phase electric motors are the backbone of industrial plants, water pumping stations, HVAC systems, compressors, conveyors, and machine tools. When a motor fails unexpectedly, it can halt production, damage connected equipment, and increase maintenance costs. Effective 3 phase electric motor troubleshooting helps engineers and technicians identify faults early, restore operation quickly, and prevent repeated failures.

Table of Contents

This guide explains practical fault diagnosis methods, common symptoms, testing procedures, and repair strategies used in real industrial environments.

Know more about low cost servomotors

Understanding the Basics of a 3 Phase Motor

Before starting troubleshooting, it is important to understand how a three phase motor operates. A balanced three phase supply creates a rotating magnetic field in the stator. This rotating field induces current in the rotor, producing torque and mechanical motion. Any disturbance in voltage balance, insulation condition, load, or cooling can disrupt this process and lead to failure.

Common components involved during troubleshooting include:

- Stator windings

- Rotor bars or rotor winding

- Bearings and shaft

- Cooling fan and ventilation paths

- Terminal box and power cables

A systematic approach to 3 phase electric motor troubleshooting always begins with understanding which component is most likely causing the fault.

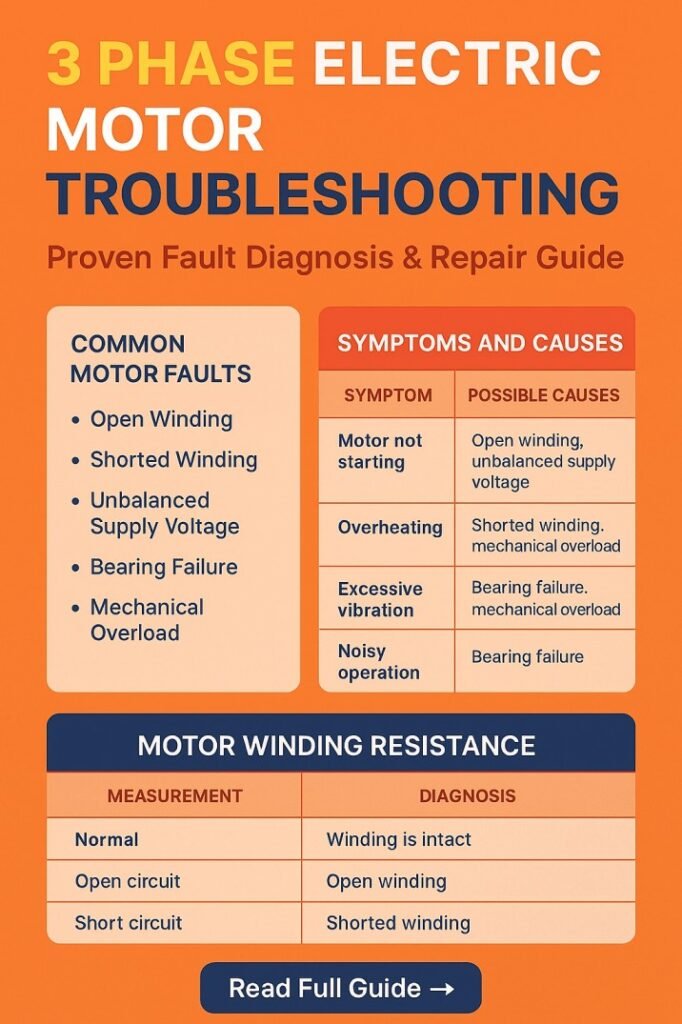

Common Symptoms and What They Indicate

Motor symptoms provide the first clues during diagnosis. Observing behavior during start-up and operation often narrows down the fault quickly.

| Symptom | Possible Cause | Initial Check |

|---|---|---|

| Motor does not start | Phase loss, blown fuse, contactor fault | Check line voltage and control circuit |

| Motor hums but does not rotate | Single phasing, mechanical jam | Measure phase currents |

| Excessive heating | Overload, low voltage, poor cooling | Check load and ventilation |

| Abnormal noise | Bearing damage, misalignment | Inspect bearings and coupling |

| Frequent tripping | Earth fault, insulation breakdown | Perform insulation resistance test |

Understanding these symptoms saves time and reduces unnecessary dismantling.

Learn more about difference between servo motor and induction motor

Electrical Faults in 3 Phase Motors

Electrical issues are among the most common causes of motor failure. Proper testing tools and safe procedures are essential for accurate diagnosis.

Single Phasing

Single phasing occurs when one phase of the supply is lost due to a blown fuse, loose terminal, or cable damage. The motor may continue running but draws high current in the remaining phases, causing overheating.

Signs of single phasing include:

- Reduced speed and torque

- Excessive current in two phases

- Rapid temperature rise

During 3 phase electric motor troubleshooting, measuring line currents with a clamp meter quickly reveals this condition.

Unbalanced Voltage

Even a small voltage imbalance can significantly increase winding temperature. A voltage imbalance of 2 percent can cause a current imbalance of up to 10 percent.

Typical causes include:

- Unequal transformer loading

- Poor cable connections

- Faulty contactors

Voltage should be measured at the motor terminals, not just at the supply panel.

Know more about VFD vs Soft Starter: Key Differences You Must Know for Motor Control

Insulation Failure

Insulation breakdown leads to earth faults or phase-to-phase short circuits. Moisture, aging, dust, and thermal stress are common contributors.

An insulation resistance tester (megger) is used to check:

- Phase to earth resistance

- Phase to phase resistance

Low readings indicate insulation deterioration and require immediate attention.

Mechanical Faults and Their Diagnosis

Mechanical problems often develop gradually but can cause sudden motor failure if ignored.

Bearing Failure

Bearings support the rotor and allow smooth rotation. Lack of lubrication, contamination, and misalignment are major causes of bearing damage.

Symptoms include:

- Grinding or rumbling noise

- Increased vibration

- Rising bearing temperature

Replacing damaged bearings on time is a critical part of 3 phase electric motor troubleshooting.

Know more about Motor Starter Size Chart: 7 Essential Insights for Better Selection

Rotor Problems

In squirrel cage motors, cracked or broken rotor bars can cause torque pulsations and uneven speed. These faults are difficult to detect visually and often require current signature analysis or load testing.

Misalignment and Overload

Poor alignment between motor and driven equipment increases mechanical stress. Overloading forces the motor to draw excess current, reducing insulation life.

Always verify:

- Shaft alignment

- Load rating versus motor capacity

Step-by-Step Troubleshooting Procedure

A structured troubleshooting process improves accuracy and safety.

- Disconnect and isolate the motor supply

- Perform visual inspection for burns, loose connections, or oil leakage

- Check supply voltage and phase sequence

- Measure no-load and full-load currents

- Test insulation resistance

- Inspect bearings and mechanical coupling

Following these steps ensures no critical check is missed during 3 phase electric motor troubleshooting.

Know more about Motor Starter Types: A Powerful Guide with 7 Key Options You’ll Appreciate

Essential Tests for Accurate Diagnosis

Proper testing confirms suspected faults and avoids guesswork.

| Test Name | Purpose | Typical Tool |

|---|---|---|

| Voltage measurement | Check balance and supply quality | Digital multimeter |

| Current measurement | Detect overload or phase loss | Clamp meter |

| Insulation resistance | Assess winding health | Megger |

| Continuity test | Identify open windings | Multimeter |

| Vibration analysis | Detect bearing or alignment issues | Vibration meter |

Recording test results helps track motor condition over time.

Repair and Corrective Actions

Once the fault is identified, corrective action should address the root cause rather than just the symptom.

Common repair actions include:

- Tightening or replacing damaged terminals

- Replacing worn bearings and seals

- Rewinding stator coils if insulation fails

- Improving cooling and ventilation

- Correcting voltage imbalance at the source

Effective repairs are a core objective of 3 phase electric motor troubleshooting, ensuring reliable long-term operation.

Preventive Maintenance to Avoid Future Failures

Preventive maintenance significantly reduces unexpected breakdowns and repair costs.

Key maintenance practices include:

- Regular insulation resistance testing

- Periodic bearing lubrication

- Cleaning cooling ducts and fans

- Monitoring current and temperature trends

- Checking alignment during shutdowns

A well-maintained motor operates efficiently and has a longer service life.

Know more about How does the star delta starter reduce starting current? Important Concepts

Safety Considerations During Troubleshooting

Safety should never be compromised during diagnosis or repair work.

Always follow these precautions:

- Isolate and lock out power supply

- Use insulated tools and PPE

- Discharge stored energy before testing

- Follow site electrical safety procedures

Safe working practices are essential during every stage of 3 phase electric motor troubleshooting.

Conclusion

Reliable motor operation is critical for industrial productivity, and failures can be costly if not handled correctly. By understanding motor behavior, recognizing early symptoms, and applying systematic testing methods, engineers can diagnose faults quickly and accurately.

Know more about Difference Between Star Delta and DOL Starter: A Comprehensive Guide

This comprehensive approach to 3 phase electric motor troubleshooting not only reduces downtime but also improves equipment life and operational efficiency. With proper maintenance and timely repairs, three phase motors can deliver dependable performance for many years.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#3PhaseElectricMotorTroubleshooting, #ThreePhaseMotor, #ElectricMotorRepair, #IndustrialMaintenance, #MotorFaultDiagnosis, #ElectricalTroubleshooting, #MotorProtection, #IndustrialAutomation, #PowerSystems, #ElectricalEngineering