Wire Size Calculator for Motors – Accurate Motor Cable Sizing Tool for Electric Loads

Choosing the correct wire size for electric motors is one of the most important steps to ensure efficient power delivery and safety. If the wire size is too small, it can cause excessive voltage drop, overheating, and energy loss. If it’s too large, it leads to unnecessary cost and installation difficulty. That’s where a Wire Size Calculator for Motors comes in — it simplifies the process and gives you accurate results in seconds.

Table of Contents

A Wire Size Calculator for Motors helps engineers, electricians, and installers find the most suitable wire gauge based on motor horsepower, voltage, phase, distance, and efficiency requirements. It eliminates guesswork and ensures compliance with standards like the NEC (National Electrical Code). Whether you’re wiring a small single-phase pump or a large industrial three-phase motor, using this calculator ensures your motor runs efficiently and safely.

Why You Need a Wire Size Calculator for Motors

Electric motors draw high starting and running currents. If the wiring is undersized, it can cause a voltage drop that leads to reduced torque, slower startup, and even damage to the winding insulation. Over time, this results in higher maintenance costs and lower equipment life.

A Wire Size Calculator for Motors makes it simple to find the correct conductor size by considering factors like:

- Motor horsepower or kilowatt rating

- Supply voltage (single-phase or three-phase)

- Length of wire run (distance between source and motor)

- Voltage drop limit (commonly 3% for motors)

- Ambient temperature and installation conditions

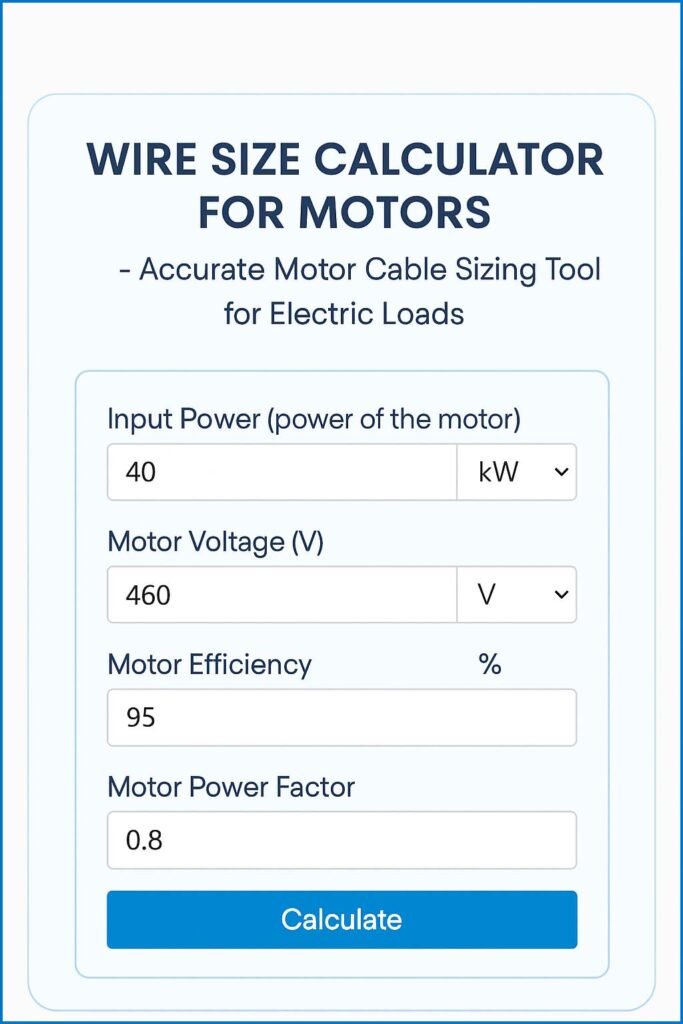

Wire Size Calculator for Motors

Determine the correct wire gauge for motor circuits based on power, voltage, and installation conditions.

Instead of referring to long NEC tables or doing manual calculations, the calculator instantly provides the recommended wire gauge. It helps you select between copper and aluminum conductors, which is important for balancing cost and performance.

Use our online tool Creepage Distance Calculator – Calculate Safe Insulation & Clearance for PCB and High Voltage Design

How the Wire Size Calculator for Motors Works

The working principle of a motor wire size calculator is based on Ohm’s law and voltage drop equations. The calculator determines the minimum wire cross-sectional area required to keep voltage drop within acceptable limits.

Here’s how the process generally works:

- You enter your motor’s rated power (in HP or kW).

- Select the operating voltage and type of phase.

- Input the length of the wire from the panel to the motor.

- Choose the allowable voltage drop percentage (usually 3% or less).

- Select the conductor type (copper or aluminum).

The calculator then processes these inputs using NEC tables and standard formulas to give you the correct wire gauge (AWG or mm²).

Basic Formula for Motor Wire Sizing

The formula used to calculate wire size is:

Wire Size (A) = (Current × Distance × 2) / (Voltage Drop × Conductivity)

Where:

- Current is the motor’s full-load current (in amperes)

- Distance is the one-way wire length (in feet or meters)

- Voltage Drop is the allowable percentage drop

- Conductivity depends on the wire material (copper or aluminum)

While professionals can use these equations manually, the Wire Size Calculator for Motors automates this process and provides results instantly.

Typical Full Load Current of Motors

The full-load current depends on the motor’s horsepower and voltage. Below is a general reference table to understand the current drawn by standard motors.

| Motor Power (HP) | Voltage (230V, 3-Phase) | Full Load Current (A) |

|---|---|---|

| 1 HP | 230 V | 3.2 A |

| 3 HP | 230 V | 9.6 A |

| 5 HP | 230 V | 15.2 A |

| 10 HP | 230 V | 28 A |

| 20 HP | 230 V | 54 A |

| 30 HP | 230 V | 80 A |

| 50 HP | 230 V | 130 A |

When you input your motor details into the Wire Size Calculator for Motors, it automatically selects the wire size that can handle these current levels efficiently without overheating.

Understanding Voltage Drop in Motor Circuits

Voltage drop is the reduction in voltage as current flows through a conductor. Motors are particularly sensitive to voltage drops because even a small reduction can affect performance and torque.

For example, a 5% drop in supply voltage can cause a motor to draw more current, which increases heating and reduces lifespan. That’s why electrical standards recommend keeping the voltage drop within 3% for motor feeders.

The Wire Size Calculator for Motors ensures this by selecting a wire gauge that maintains the voltage within acceptable limits. It factors in conductor material resistance and the total distance of the circuit to deliver accurate results.

Use our online tool DC Circuit Breaker Sizing Calculator – Accurate Tool for DC Load Protection

Example of Voltage Drop Calculation

Suppose you have a 10 HP three-phase motor at 230V located 150 feet from the power panel. If the full-load current is 28A and the voltage drop limit is 3%, the calculator quickly determines the correct wire size (for example, 6 AWG copper) to ensure minimal losses and safe operation.

Without using a calculator, performing this calculation manually could take several steps and reference charts, increasing the chances of error.

Choosing Between Copper and Aluminum Wires

When using the Wire Size Calculator for Motors, you can choose between copper and aluminum conductors. Each has its own advantages.

Copper wires are more efficient, have lower resistance, and require smaller sizes for the same load. They are ideal for short-distance or high-reliability applications.

Aluminum wires are lighter and cheaper but require larger cross-sectional areas for the same current. They are suitable for longer runs or where cost efficiency is a priority.

| Property | Copper Wire | Aluminum Wire |

|---|---|---|

| Conductivity | Higher | Lower |

| Size for Same Load | Smaller | Larger |

| Cost | Higher | Lower |

| Weight | Heavier | Lighter |

| Applications | Industrial, Motors | Long Distance, Utility |

The calculator provides recommended sizes for both types, helping you make a cost-performance decision quickly.

Factors Affecting Motor Wire Sizing

Several environmental and technical factors influence wire selection. A Wire Size Calculator for Motors takes these into account for precise recommendations.

Motor Load Type – Continuous or intermittent loads impact the required wire gauge. Continuous loads generate more heat and need thicker wires.

Use our online tool Electricity Load Calculator (kVA) According to IEC and NEC

Ambient Temperature – High temperatures reduce conductor capacity, so the calculator adjusts for temperature correction.

Conduit Type – Whether the wire is installed in PVC conduit, tray, or underground affects heat dissipation.

Starting Current – Motors have high inrush current at startup. The calculator ensures the wire can handle the peak current safely.

Efficiency and Power Factor – The tool accounts for power factor and motor efficiency when calculating the actual current draw.

Benefits of Using a Wire Size Calculator for Motors

Using a motor wire size calculator offers several advantages for professionals and DIY installers alike.

- Time-saving: Instantly get wire size recommendations without referring to multiple tables.

- Accuracy: Uses NEC-based formulas for precise sizing.

- Safety: Prevents overheating, short circuits, and fire risks.

- Energy efficiency: Reduces power losses due to voltage drop.

- Cost optimization: Avoids oversizing wires unnecessarily.

When designing motor circuits for factories, farms, or solar-powered pumps, this calculator becomes an essential design tool.

Real-world Applications of Motor Wire Sizing

The Wire Size Calculator for Motors is widely used across various industries and installations, including:

- Industrial plants with multiple motors

- HVAC and water pump systems

- Agricultural tubewell motors

- Commercial building motor panels

- Solar and renewable energy systems

- Residential motor-driven appliances

Each of these systems requires accurate wire sizing to maintain performance and reduce maintenance costs.

Use our online tool MM to AWG Wire Size Calculator According to IEC and NEC

Example Case

Consider a 7.5 HP, 415V three-phase motor running 100 meters from the main panel. Entering these values in the calculator along with a 3% voltage drop and copper wire selection gives a result of approximately 4 mm² cable size. The calculator ensures that even during motor starting conditions, the voltage remains within the safe range.

Comparison of Common Wire Sizes for Motors

| Wire Gauge (AWG) | Copper Ampacity (A) | Aluminum Ampacity (A) | Suitable Motor HP Range (230V) |

|---|---|---|---|

| 14 AWG | 15 | 10 | Up to 0.5 HP |

| 12 AWG | 20 | 15 | Up to 1 HP |

| 10 AWG | 30 | 25 | 1 to 3 HP |

| 8 AWG | 40 | 35 | 3 to 5 HP |

| 6 AWG | 55 | 45 | 5 to 10 HP |

| 4 AWG | 70 | 60 | 10 to 15 HP |

| 2 AWG | 95 | 75 | 15 to 25 HP |

| 1/0 AWG | 125 | 100 | 25 to 40 HP |

The calculator uses similar internal data but adapts it dynamically to the entered conditions for more accurate sizing.

Why Accurate Wire Sizing Matters

Choosing the right wire size is more than just meeting code requirements. It affects motor performance, safety, and overall energy consumption. Proper sizing ensures:

- Lower operating temperatures

- Longer motor and wire lifespan

- Better voltage regulation

- Reduced energy losses

- Compliance with NEC and IEC standards

The Wire Size Calculator for Motors simplifies all these calculations and ensures your electrical system runs efficiently.

Conclusion

Selecting the correct wire size for motors doesn’t have to be complex. With the Wire Size Calculator for Motors, you can easily determine the right conductor size for any motor application, whether small residential systems or large industrial installations. The calculator factors in all crucial parameters — voltage, distance, current, and material type — to ensure safe and efficient operation.

Use our online tool Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

If you’re an engineer, electrician, or system designer, integrating a Wire Size Calculator for Motors into your workflow saves time, enhances accuracy, and ensures compliance with safety standards. Use it for your next project and experience how simple and precise electrical design can be.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#WireSizeCalculator, #MotorWiring, #ElectricalEngineering, #MotorWireSize, #CableSizing, #MotorLoadCalculator, #ElectricalSafety, #MotorEfficiency, #PowerCalculation, #IndustrialMotors, #WireGauge, #MotorConnection, #ElectricMotorDesign, #VoltageDrop, #ElectricalTools

Having read this I thought it was very informative. I appreciate you taking the time and effort to put this article together. I once again find myself spending way to much time both reading and commenting. But so what, it was still worth it!