What Size Earth Cable for Bonding: Best Guide

Choosing what size earth cable for bonding is one of the most important tasks in any electrical installation. A correct bonding conductor protects people, assets, and equipment from electric shock and fire hazards. It also ensures that all metallic parts maintain the same electrical potential.

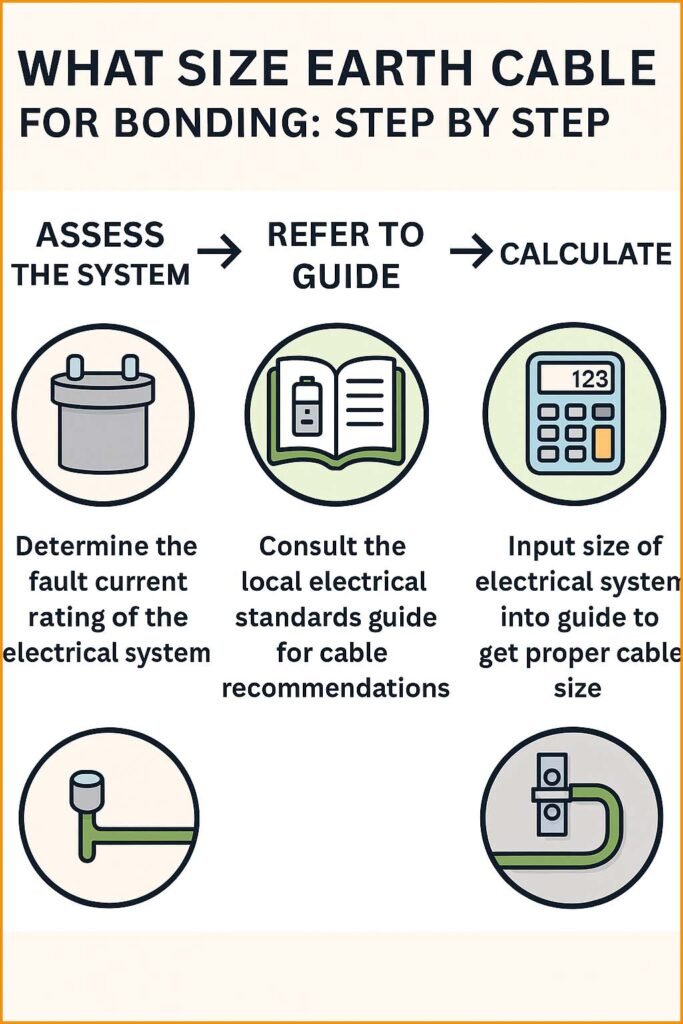

In this guide, you will learn the complete step-by-step method for selecting the right bonding conductor, the apparatus used for measurement and verification, and the relevant IEC standards. This article also anchors the pillar content earthing cable size as per IEC to help you build a deeper understanding of international compliance.

Table of Contents

Many electricians, engineers, and inspectors face confusion when choosing an earthing or bonding conductor. In practice, the selection depends on fault current, short-circuit duration, conductor material, installation type, and regulatory standards. The steps below simplify the process so that you can select the correct bonding cable quickly and confidently.

Understanding Bonding and Earthing

Bonding links two metallic parts that are not normally energized. Earthing connects live parts or bonded parts directly to earth. Both reduce the touch voltage and ensure quick operation of protective devices during faults. Bonding conductors are sized so that they can safely carry expected fault currents without overheating or melting.

Know more about Grounding vs Bonding: Key Differences Explained

Metallic pipes, structural steel, cable trays, HVAC ducts, storage tanks, and switchgear bodies are common items that require bonding.

IEC Standards Used for Bonding Cable Selection

Several IEC standards define the performance and sizing requirements for bonding and earthing conductors. The most important ones include:

- IEC 60364-5-54 – Details the selection, installation, and sizing of earthing and protective conductors.

- IEC 60439 / IEC 61439 – Defines requirements for low-voltage switchgear and controlgear assemblies.

- IEC 60228 – Specifies the cross-sectional areas of conductors.

- IEC 60909 – Provides methods for calculating fault current.

Following these standards ensures your bonding conductors meet global safety expectations and align with earthing cable size as per IEC.

Apparatus Used in Bonding and Earthing Verification

Several instruments support proper selection and confirmation of bonding conductor size:

Earth Resistance Tester

Used to measure soil resistance and continuity between bonded parts.

Micro-Ohmmeter

Measures the resistance of bonding straps and earth cables. Use our online tool 3 phase cable size calculator

Clamp-On Ground Tester

Allows non-intrusive measurement of bonding conductor performance.

Insulation Resistance Tester

Confirms insulation quality around earthing and bonding cables.

Short-Circuit Fault Analyzer

Used during design to calculate the fault level for sizing conductors.

Using these tools ensures accurate installation and verification.

Step-by-Step Guide to Determine What Size Earth Cable for Bonding

Step 1: Identify the Type of Bonding

There are three main types:

- Main equipotential bonding

- Supplementary bonding

- Protective bonding within equipment

Main bonding requires larger conductors because fault currents are higher.

Step 2: Determine the Fault Current

The prospective short-circuit current (PSCC) is essential. Use system data or calculate using IEC 60909. Higher fault current requires a larger cable.

Step 3: Determine the Disconnection Time

Protective devices such as MCBs, MCCBs, fuses, or relays disconnect fault current. The disconnection time determines thermal stress on the bonding cable. Try our free online tool today ev charger cable size calculator

Step 4: Apply the IEC Sizing Formula

IEC 60364-5-54 uses this formula:

S = (I × √t) / k

Where:

S = Cross-sectional area in mm²

I = Fault current in amperes

t = Disconnection time in seconds

k = Material constant based on conductor type and insulation

Typical values of k:

Copper (PVC): 115

Copper (XLPE): 143

Aluminium (PVC): 76

Step 5: Choose Material and Insulation

Copper is preferred for bonding due to high conductivity and strength. Aluminium is allowed but less common.

For outdoor or harsh environments, consider XLPE or PVC insulation.

Step 6: Apply Minimum Sizes from IEC

IEC 60364 provides minimum allowable sizes. These ensure safety even when fault calculations vary.

Step 7: Verify Using Tables and Manufacturer Data

Once the cable size is selected, verify thermal capacity, installation condition, and temperature rating. Access our powerful online calculator now star delta motor cable size calculator

IEC Minimum Bonding Cable Sizes

The table below summarizes minimum conductor sizes from IEC requirements.

Minimum Bonding Conductor Size (IEC 60364-5-54)

| Type of Conductor | Minimum Size Copper (mm²) | Minimum Size Aluminium (mm²) |

|---|---|---|

| Main equipotential bonding | 6 mm² | 16 mm² |

| Supplementary bonding | 2.5 mm² (protected), 4 mm² (unprotected) | 6 mm² |

| Protective bonding inside equipment | 1.5–4 mm² depending on device rating | 2.5–6 mm² |

These are minimum sizes. Actual required size may be higher based on fault levels.

Step-by-Step Practical Example

System Data

Fault Current: 6 kA

Disconnection Time: 0.4 seconds

Material: Copper

Apply the formula:

S = (I × √t) / k

S = (6000 × √0.4) / 115

√0.4 = 0.632

S = (6000 × 0.632) /115

S = 3792 / 115

S ≈ 33 mm²

The selected bonding conductor should therefore be 35 mm² copper based on standard cable sizes.

This example illustrates that many practical installations require larger-than-minimum bonding conductors. Get instant results with our online tool earth cable size calculator

Installation Considerations for Bonding Conductors

Route Selection

Use the shortest and most direct path. Shorter lengths reduce impedance and touch voltage.

Mechanical Protection

Provide conduits or trunking for exposed conductors.

Corrosion Protection

Use tinned copper in corrosive environments or ensure joints are protected.

Jointing and Termination

Use proper lugs, compression tools, and corrosion inhibitor paste where required.

Labeling

Bonding points should be labeled for easy identification during inspections.

Importance of Correct Bonding Cable Size

Choosing the correct conductor size prevents:

- Overheating during a fault

- Damage to metallic systems

- Shock hazards

- Loss of protective device operation

- Non-compliance with IEC and local codes

Incorrect bonding is one of the leading causes of equipment failure and electrical hazards. Start using our easy-to-use online tool earthing cable size calculator

Table: Comparison of Common Bonding Cable Sizes for Typical Installations

| Application Type | Typical Size Copper (mm²) | Notes |

|---|---|---|

| Domestic main bonding | 6–10 mm² | Based on typical 3–6 kA fault levels |

| Industrial bonding | 16–35 mm² | Higher fault levels and larger equipment |

| Generator bonding | 35–70 mm² | Higher short-circuit and thermal stress |

| Substation bonding | 50–95 mm² | Large fault currents and multiple earth paths |

Use these values only as reference. Always calculate using the IEC method.

Final Verification Before Commissioning

Before energizing the system:

- Test continuity of bonding conductors

- Measure earth fault loop impedance

- Confirm labels are correct

- Verify conductor routing and terminations

- Ensure compliance with earthing cable size as per IEC

These final checks help ensure long-term reliability.

Conclusion

Understanding what size earth cable for bonding is essential for safe electrical installations. The correct selection depends on fault current, disconnection time, material, and IEC requirements. By following the step-by-step method outlined here and using the correct apparatus, you can confidently select and install bonding conductors that meet global standards. Calculate instantly with our smart online tool cable size calculator australia

As you design and verify your system, always anchor your decisions around earthing cable size as per IEC to ensure safety, reliability, and compliance with internationally recognized practices.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#earthing, #earthcablebonding, #electricalbonding, #bondingcablesize, #earthinginstallation, #electricalsafety, #groundingcables, #IECelectrical, #earthcablesizing, #safetyelectricalsystems