VLF Tan Delta Testing of MV Cables: Ensure Reliable High-Voltage Cable Performance

Medium voltage (MV) cables form the backbone of modern electrical networks, connecting substations, transformers, and industrial loads efficiently. However, the reliability of these cables depends heavily on their insulation condition. Aging, moisture ingress, and manufacturing defects can significantly compromise insulation, leading to unexpected failures. Among the various diagnostic methods available, VLF Tan Delta testing of MV cables has emerged as a critical technique for assessing insulation integrity and ensuring reliable high-voltage cable performance.

Table of Contents

VLF, or Very Low Frequency, testing allows engineers to apply high AC voltage at a frequency significantly lower than standard mains, typically 0.01 Hz to 0.1 Hz. When combined with Tan Delta measurements, this method provides precise insight into insulation quality, identifying defects that traditional testing might overlook. Understanding this process, its benefits, and practical applications is essential for electrical engineers, maintenance teams, and asset managers tasked with maintaining cable networks.

What is VLF Tan Delta Testing of MV Cables?

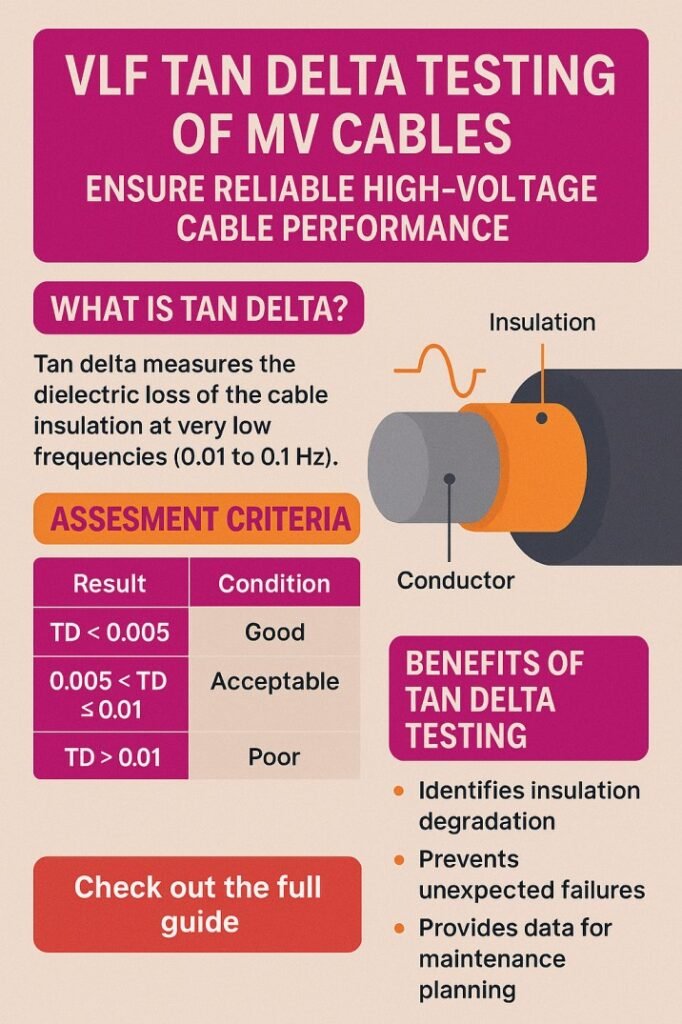

VLF Tan Delta testing of MV cables is a diagnostic procedure used to evaluate the insulation condition of medium voltage power cables. The test involves applying a very low-frequency AC voltage to the cable while simultaneously measuring the dissipation factor (Tan Delta), which indicates the dielectric losses within the insulation.

Tan Delta is a parameter that reflects the ratio of resistive to capacitive current in the insulation. Higher Tan Delta values often signal insulation degradation, moisture presence, or voids within the dielectric material. By analyzing these readings under controlled VLF conditions, engineers can detect early-stage defects, assess cable health, and make informed decisions regarding maintenance or replacement.

Know more about High Voltage Testing Procedures for Electrical Panels: Step by Step

Why Use VLF for MV Cables?

Traditional high-voltage testing at power frequency (50/60 Hz) is not always practical for MV cables due to their length and capacitance, which can result in excessive test currents and heating. VLF testing, by contrast, reduces capacitive stress while maintaining the ability to detect insulation weaknesses. This makes it ideal for:

- Long MV cables in underground or industrial installations

- Cables with complex jointing or terminations

- Systems where conventional AC testing could risk further insulation damage

Key Benefits of VLF Tan Delta Testing

- Early Defect Detection: Identifies insulation deterioration before catastrophic failure.

- Reduced Test Stress: Low frequency AC minimizes thermal and mechanical stress on cable insulation.

- Accurate Assessment: Tan Delta values provide quantitative insights into insulation condition.

- Enhanced Reliability: Supports predictive maintenance strategies, reducing unexpected outages.

- Cost-Effective Maintenance: Helps prioritize cables for repair or replacement, saving operational costs.

Know more about Power Quality Analyzer Buying Guide for Engineers

How VLF Tan Delta Testing Works

The procedure for VLF Tan Delta testing of MV cables involves several critical steps:

- Cable Preparation: Ensure cable terminations are clean, joints are properly sealed, and the cable is isolated from the network.

- Connection Setup: Connect the VLF test set to the cable, including a measuring unit for Tan Delta readings.

- Voltage Application: Apply VLF voltage gradually, typically between 0.1 Hz and 0.01 Hz, until the rated test voltage is reached.

- Tan Delta Measurement: Record Tan Delta readings at incremental voltage levels. A trend of increasing Tan Delta indicates potential insulation defects.

- Analysis and Reporting: Compare results against baseline values or industry standards to determine cable health.

A typical Tan Delta test may produce a curve plotting the dissipation factor against applied voltage, helping engineers distinguish between localized and distributed defects.

Know more about Top 12 Electrical Testing Equipment Suppliers in USA

Table: Typical Tan Delta Values for MV Cables

| Cable Type | Healthy Tan Delta | Warning Range | Critical Range |

|---|---|---|---|

| XLPE 11 kV | <0.5% | 0.5% – 1.0% | >1.0% |

| EPR 11 kV | <0.7% | 0.7% – 1.2% | >1.2% |

| PILC 11 kV | <0.8% | 0.8% – 1.5% | >1.5% |

| MV Cables 33 kV | <0.5% | 0.5% – 1.0% | >1.0% |

This table provides a guideline for interpreting Tan Delta results, helping engineers decide on cable maintenance strategies.

Applications in Real-World Scenarios

VLF Tan Delta testing of MV cables is widely used in industrial plants, utility networks, and renewable energy installations. Its ability to detect early-stage insulation problems makes it particularly valuable in:

- Underground cable systems prone to moisture ingress

- High-reliability networks requiring minimal downtime

- Cables with complex terminations, joints, and cross-linked polyethylene (XLPE) insulation

By identifying vulnerable sections, operators can replace or repair cables before failures disrupt operations, reducing both safety risks and financial losses.

Know more about Insulation Resistance Testing: Step-by-Step Process

Comparing VLF Tan Delta Testing and Other Diagnostic Methods

While various methods exist for cable testing, VLF Tan Delta testing offers unique advantages:

| Testing Method | Advantages | Limitations |

|---|---|---|

| DC Hipot Testing | Simple, detects gross insulation faults | May not detect partial degradation |

| AC Power Frequency Test | Effective for short cables | High current risk, impractical for long runs |

| Partial Discharge Test | Identifies localized insulation faults | Requires sophisticated equipment |

| VLF Tan Delta Test | Detects early-stage insulation deterioration with low stress | Cannot identify very small local voids without advanced analysis |

The comparison shows that VLF Tan Delta testing of MV cables is ideal for preventive maintenance and long cable circuits, offering a balance between accuracy, safety, and practicality.

Know more about Best Megger Testers for Industrial Use

Factors Affecting Tan Delta Readings

Accurate interpretation of Tan Delta measurements requires understanding influencing factors:

- Cable Age: Older cables may exhibit higher Tan Delta due to natural insulation aging.

- Temperature: Insulation properties change with temperature; readings should be temperature-compensated.

- Moisture Content: Water ingress significantly increases dielectric losses.

- Test Voltage Level: Tan Delta may vary at different applied voltages; progressive testing is recommended.

By considering these factors, engineers can avoid false positives and make reliable maintenance decisions.

Safety Considerations

Though VLF testing uses low-frequency voltage, the applied levels are still high and can pose serious hazards. Safety measures include:

- Proper earthing of the test setup

- Clear isolation of test cables from live circuits

- Use of personal protective equipment (PPE)

- Following manufacturer guidelines and industry standards

Adhering to safety protocols ensures personnel protection and prevents equipment damage.

Know more about Top 20 Electrical Testing Tools Which You Must Have

Predictive Maintenance Using VLF Tan Delta Testing

Integrating VLF Tan Delta testing of MV cables into a predictive maintenance program allows utilities and industries to:

- Schedule maintenance based on insulation condition rather than age

- Extend cable life through timely interventions

- Reduce unplanned outages and operational costs

- Maintain high network reliability

With modern VLF test sets offering automated Tan Delta trending, maintenance teams can track cable health over years and predict failures before they occur.

Table: Maintenance Action Based on Tan Delta Results

| Tan Delta Range | Recommended Action |

|---|---|

| Normal (<0.5%) | Continue routine monitoring |

| Slightly Elevated | Schedule detailed inspection |

| High (>1%) | Immediate maintenance or replacement |

| Rapidly Rising | Emergency intervention required |

This structured approach allows engineers to make data-driven decisions and optimize cable management strategies.

Explore all about vlf testing procedure

Conclusion

VLF Tan Delta testing of MV cables is a vital tool for ensuring reliable high-voltage cable performance. By accurately assessing insulation condition under low-frequency stress, this technique enables early defect detection, enhances system reliability, and supports predictive maintenance strategies. Industrial plants, utilities, and network operators benefit from reduced downtime, cost savings, and safer operations.

In a world where electrical networks are growing increasingly complex, adopting advanced diagnostic techniques like VLF Tan Delta testing is no longer optional—it is essential for sustaining uninterrupted power delivery and protecting critical infrastructure. Proper planning, testing, and analysis ensure that MV cables operate safely and efficiently throughout their service life. Find all about Partial Discharge vs Tan Delta Cable Testing: Important Key Differences Every Engineer Must Know

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#VLFTanDelta, #MVcableTesting, #ElectricalTesting, #PartialDischarge, #CableDiagnostics, #HighVoltageTesting, #TanDeltaTest, #PowerCableHealth, #MVEquipment, #ElectricalMaintenance