Transformers Diagnostic Testing – Professional Guide to Advanced Tools, Methods & Power System Reliability

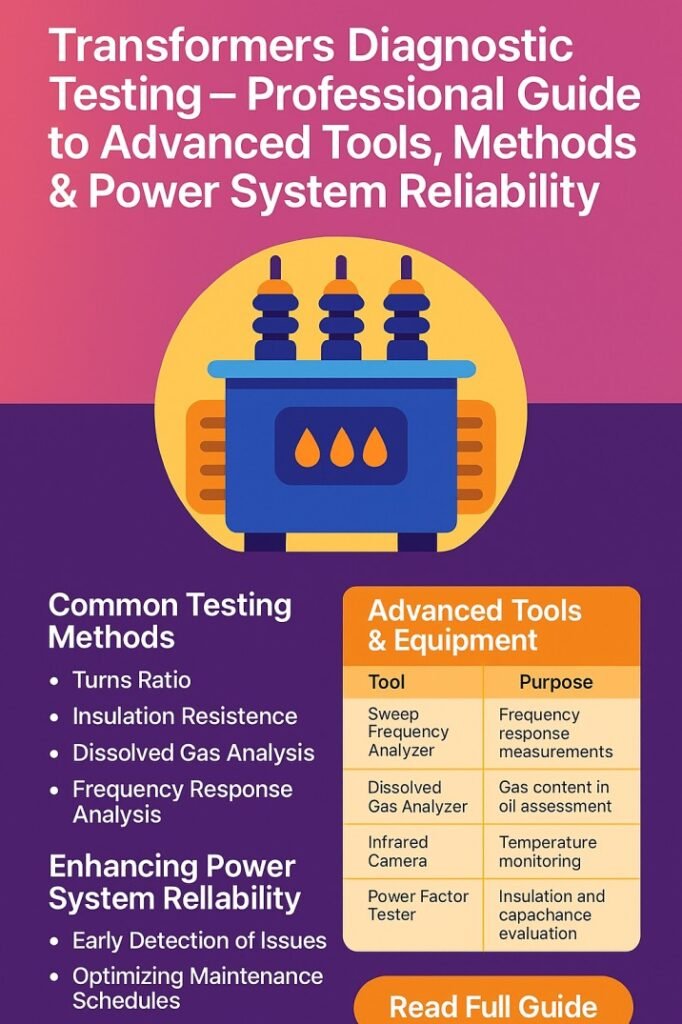

Power transformers remain among the most valuable and critical assets in electrical networks. Their reliability directly affects industrial continuity, grid stability, and long-term operational costs. Because of this importance, transformers diagnostic testing has evolved from routine inspection into a data-driven engineering discipline focused on early fault detection and lifecycle optimization. A structured testing strategy allows engineers to evaluate insulation health, winding condition, and thermal performance without intrusive dismantling.

Table of Contents

This professional guide explains modern practices, tools, and evaluation methods that define transformers diagnostic testing today. It focuses on practical application, field relevance, and interpretation techniques that support dependable power system operation.

Understanding the Purpose of Diagnostic Evaluation

Transformers operate under electrical, thermal, and mechanical stress. Age, overload, contamination, and environmental exposure gradually degrade insulation and structural integrity. Transformers diagnostic testing aims to detect such degradation before it becomes catastrophic.

Use our online tool for free Transformer Neutral Current Calculator – Accurate Neutral Current Estimation

Instead of relying on corrective maintenance, utilities and industrial operators use predictive approaches. These approaches combine condition monitoring, oil analysis, and electrical measurement to establish asset health indicators. The outcome is improved outage planning and better capital investment decisions.

Key objectives typically include:

- Identifying insulation deterioration

- Detecting winding displacement or deformation

- Assessing moisture and contamination levels

- Evaluating core and tap changer condition

- Predicting remaining service life

When implemented consistently, transformers diagnostic testing transforms maintenance programs from reactive to preventive and predictive models.

Categories of Diagnostic Methods

Different test categories target different components of transformer health. Combining them provides a holistic picture of operational condition.

Electrical Tests

Electrical measurements evaluate winding integrity, insulation resistance, and dielectric strength. These methods remain foundational in transformers diagnostic testing because they offer repeatable benchmarks across service years.

Try our free online tool Transformer Temperature Rise Calculator: Accurate and Easy Guide

Common electrical evaluations include:

| Test Method | Main Objective | Typical Insight |

|---|---|---|

| Insulation Resistance | Check insulation dryness | Moisture or contamination presence |

| Winding Resistance | Verify conductor continuity | Loose joints or tap issues |

| Turns Ratio Test | Confirm voltage ratio accuracy | Winding faults or core issues |

| Power Factor Test | Assess dielectric losses | Aging insulation condition |

These measurements are straightforward and widely standardized, making them reliable trend indicators when repeated periodically.

Oil-Based Analysis

Liquid insulation acts both as coolant and diagnostic medium. Chemical changes reveal internal stress conditions. For this reason, oil evaluation forms a central pillar of transformers diagnostic testing programs worldwide.

| Oil Analysis Type | Parameter Measured | Diagnostic Value |

|---|---|---|

| Dissolved Gas Analysis | Fault gases | Detects arcing, overheating |

| Moisture Content | Water concentration | Indicates insulation risk |

| Acidity Test | Oil degradation | Oxidation level |

| Dielectric Breakdown | Voltage withstand | Insulation strength |

Gas trend interpretation often provides early warning of internal faults long before electrical symptoms appear.

Use our tool online at no cost Transformer Losses Calculation Tool – Accurate & Easy Energy Loss Analysis

Advanced Diagnostic Techniques

Traditional testing remains important, but modern reliability demands deeper insight. Advanced instruments now enhance transformers diagnostic testing by identifying subtle structural or dielectric anomalies.

Frequency Response Analysis

This method evaluates winding geometry by measuring frequency-dependent impedance. Mechanical movement caused by transport shock or fault current can be detected with high sensitivity. It is particularly valuable after short circuit events or relocation.

Partial Discharge Measurement

Localized insulation defects emit small electrical discharges that may not immediately cause failure. Monitoring these emissions reveals hidden deterioration. Portable sensors and online monitoring systems have expanded the scope of transformers diagnostic testing in substations and industrial plants.

Access our online tool completely free Transformer Vector Group Calculation Tool | Easy & Accurate Vector Group Calculator

Thermal Imaging

Infrared scanning identifies abnormal heating at bushings, connections, and cooling systems. Because temperature correlates strongly with insulation aging, thermal evaluation complements electrical data. Engineers frequently integrate imaging results into overall transformers diagnostic testing assessments.

Role of Digital Monitoring and Data Analytics

Digitalization has transformed asset management practices. Sensors continuously collect load, temperature, and gas data. Analytics platforms compare these values against predictive models, enabling trend recognition.

Benefits include:

- Early anomaly detection

- Reduced manual inspection frequency

- Improved decision confidence

- Optimized maintenance scheduling

As utilities adopt smart grid concepts, transformers diagnostic testing increasingly merges with automated monitoring environments. Data integration supports condition-based maintenance rather than calendar-based routines.

Get started with our free online tool Transformer Efficiency Calculator – Calculate Power, Losses & Performance Instantly

Testing Frequency and Planning Considerations

Effective implementation depends on proper scheduling. Over-testing wastes resources, while under-testing increases risk exposure. Engineers typically align testing intervals with transformer criticality, age, and operating environment.

| Transformer Importance | Suggested Testing Interval | Monitoring Approach |

|---|---|---|

| Critical Grid Unit | Annual comprehensive review | Continuous monitoring |

| Industrial Process Unit | Every 1–2 years | Routine sampling |

| Secondary Distribution | Every 3–5 years | Basic inspection |

Environmental stress, loading pattern, and historical results may justify adjustments. Transformers diagnostic testing should always reflect risk-based asset management principles.

Interpretation and Engineering Judgment

Data collection alone does not guarantee reliability improvement. Skilled interpretation converts raw measurements into actionable decisions. Engineers must correlate multiple indicators rather than relying on isolated values.

Use our online tool without paying anything Transformer Impedance Calculation Tool – Accurate Transformer Impedance Calculator for Engineers

For instance, increasing dielectric loss combined with elevated moisture content strengthens evidence of insulation aging. Similarly, gas generation patterns aligned with thermal hotspots confirm overheating scenarios. Integrated evaluation remains a defining feature of effective transformers diagnostic testing practice.

Decision outcomes may include:

- Continued operation

- Load reduction

- Scheduled refurbishment

- Immediate shutdown

These decisions protect both personnel safety and infrastructure investment.

Contribution to Power System Reliability

Reliable transformers stabilize voltage levels and maintain energy continuity. Failures disrupt production lines, damage connected equipment, and increase restoration costs. By detecting issues early, transformers diagnostic testing contributes directly to system resilience.

Operational advantages include:

- Lower outage probability

- Extended equipment lifespan

- Improved safety margins

- Reduced emergency repair expenses

Enjoy free access to our online tool Step-Down Transformer Calculator – Accurate Voltage & Power Conversion Tool

From utility transmission networks to renewable generation plants, consistent evaluation strategies reinforce dependable energy delivery.

Integrating Diagnostics into Lifecycle Management

Asset management frameworks now integrate transformers diagnostic testing into procurement, commissioning, operation, and end-of-life planning. Early baseline testing establishes performance references. Periodic evaluation tracks condition drift over decades.

Lifecycle integration involves:

- Acceptance testing before energization

- Routine monitoring during service

- Post-fault verification

- Refurbishment evaluation

- Decommissioning decision support

This structured approach aligns technical insight with financial planning, ensuring capital resources are allocated effectively.

Future Direction of Diagnostic Practices

Technology trends indicate continued advancement in sensing accuracy and automation. Artificial intelligence models increasingly assist engineers by correlating large datasets across fleets of assets. Portable instruments grow lighter and faster, supporting field efficiency.

Test our online tool for free Transformer Full Load Current Calculator – Accurate Load & Current Calculation Tool for Transformers

Emerging developments influencing transformers diagnostic testing include:

- Cloud-based condition databases

- Acoustic emission sensing

- Fiber optic temperature measurement

- Automated reporting systems

While tools evolve, engineering fundamentals remain essential. Sound understanding of insulation physics and electromagnetic behavior ensures meaningful interpretation of results.

Conclusion

Maintaining transformer reliability requires more than routine inspection. It demands a structured program built on measurement accuracy, analytical skill, and strategic planning. Transformers diagnostic testing provides this framework by revealing hidden deterioration before it escalates into operational failure.

Start using our online tool today — it’s free Transformer Short Circuit Calculator – Accurate Fault Current & Transformer Protection Tool

Through electrical evaluation, oil assessment, advanced measurement, and digital monitoring, engineers gain comprehensive visibility into asset health. When applied consistently, transformers diagnostic testing strengthens maintenance efficiency, reduces operational risk, and supports long-term power system stability. As energy networks expand and diversify, disciplined diagnostic practice will remain indispensable for sustaining dependable electrical infrastructure.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformersDiagnosticTesting, #TransformerTesting, #PowerTransformerMaintenance, #ElectricalDiagnostics, #HighVoltageTesting, #ConditionMonitoring, #PowerSystems, #ElectricalEngineering, #TransformerHealth, #PredictiveMaintenance