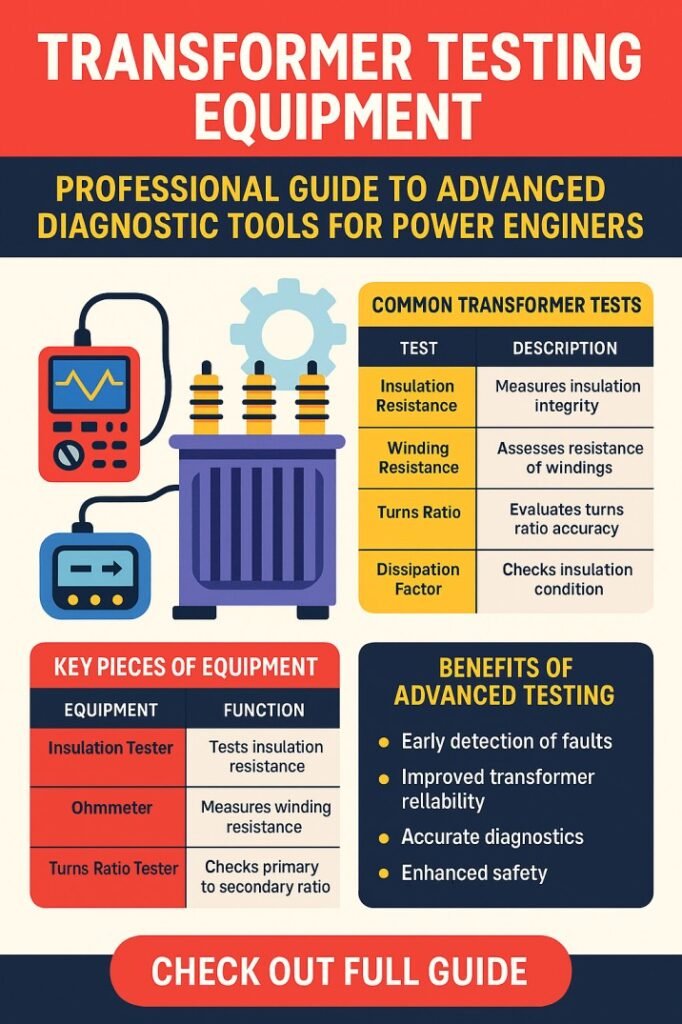

Transformer Testing Equipment – Professional Guide to Advanced Diagnostic Tools for Power Engineers

Power transformers are among the most valuable and sensitive assets in any electrical network. Their performance directly influences system stability, safety, and reliability. Because of this, the selection and proper use of transformer testing equipment is a core responsibility for power engineers involved in installation, commissioning, and maintenance. From factory acceptance checks to field diagnostics, modern instruments provide precise insights into insulation health, winding integrity, and dielectric condition. Understanding these tools is not just about compliance with standards; it is about preventing unexpected outages and extending equipment life.

Table of Contents

This guide explains the essential categories of transformer testing equipment, the purpose behind each diagnostic method, and practical considerations when applying them in real environments. It is written for engineers who want a structured, professional reference that aligns with everyday power system practice.

Importance of Transformer Diagnostics in Power Systems

Reliable energy delivery depends on early detection of faults such as insulation degradation, winding displacement, or moisture contamination. The right transformer testing equipment helps engineers identify hidden defects before they evolve into costly failures. Routine condition assessment also supports asset management strategies, allowing maintenance teams to prioritize repairs and schedule replacements efficiently.

Advanced diagnostics contribute to operational safety. They ensure compliance with international standards, validate design performance, and confirm that transformers meet performance benchmarks after transportation or repair. Engineers working in substations, renewable plants, and industrial networks increasingly rely on portable digital analyzers to complete these evaluations quickly without compromising accuracy.

Know more about Top 20 Electrical Testing Tools Which You Must Have

Core Categories of Transformer Testing Equipment

Testing devices used across the lifecycle of a transformer can be grouped according to their diagnostic function. Each category addresses a different physical property, such as resistance, insulation behavior, or dielectric quality.

| Equipment Type | Primary Measurement | Typical Application | Diagnostic Insight |

|---|---|---|---|

| Winding resistance meter | DC resistance of windings | Commissioning and maintenance | Detects loose connections and conductor damage |

| Insulation resistance tester | Megohm-level insulation values | Routine field checks | Identifies moisture or contamination |

| Transformer turns ratio tester | Ratio and phase angle | Installation verification | Confirms winding configuration accuracy |

| Power factor test set | Dielectric losses | Condition assessment | Evaluates insulation aging |

| Sweep frequency response analyzer | Mechanical response signature | Transport inspection | Reveals winding deformation |

| Oil breakdown voltage tester | Dielectric strength of oil | Oil quality testing | Indicates contamination or aging |

This range illustrates how transformer testing equipment covers both electrical and mechanical aspects, ensuring comprehensive evaluation across operating conditions.

Know more about Best Megger Testers for Industrial Use

Electrical Measurement Instruments

Electrical parameters often provide the first indication of internal problems. Accurate measurement tools enable engineers to compare results against baseline factory data or previous inspection records.

Winding Resistance Measurement

Resistance testing verifies uniform current flow through transformer windings. A micro-ohmmeter designed for transformer testing equipment applies stable current and records voltage drop. Abnormal readings may indicate shorted turns, poor joints, or conductor damage. Temperature correction is essential to ensure meaningful comparison with reference values.

Turns Ratio Analysis

Ratio verification confirms the relationship between primary and secondary windings. Digital ratio analyzers simplify this task by automatically calculating deviation percentages and vector group identification. Reliable transformer testing equipment ensures precise ratio measurement, reducing the risk of incorrect connections during commissioning.

Know more about Insulation Resistance Testing: Step-by-Step Process

Insulation Resistance Testing

Insulation resistance testers, commonly used during routine checks, measure leakage current through solid insulation. High readings indicate healthy insulation, while declining values suggest moisture ingress or deterioration. Modern units integrate polarization index and dielectric absorption ratio calculations, providing deeper insight into insulation behavior.

Dielectric Evaluation Tools

Dielectric properties reveal how well insulation materials can withstand electrical stress. Engineers use specialized transformer testing equipment to monitor insulation aging and contamination.

Power Factor and Dissipation Factor Analysis

Power factor testing determines energy losses within insulation systems. Equipment designed for this purpose measures phase differences between voltage and current, indicating deterioration trends. By repeating tests over time, engineers can establish condition-based maintenance schedules.

Know more about Top 12 Electrical Testing Equipment Suppliers in USA

Capacitance Measurement

Capacitance testing helps detect winding displacement or insulation breakdown. Changes from baseline values can indicate mechanical movement or internal faults. When combined with other dielectric tests, it forms part of a thorough diagnostic approach.

Mechanical Integrity Assessment

Electrical tests alone cannot reveal mechanical distortions caused by short circuits or transport impacts. Dedicated transformer testing equipment addresses this limitation.

Sweep Frequency Response Analysis

Frequency response analysis compares the transformer’s response to injected signals across a spectrum. Differences from historical signatures highlight structural changes in windings or core assembly. This technique is widely used after relocation or fault events to verify mechanical stability.

Vibration and Acoustic Monitoring

Specialized sensors detect abnormal vibration patterns during operation. Although often considered supplementary, these tools help identify core looseness or structural imbalance that might otherwise go unnoticed.

Oil and Thermal Condition Monitoring

Liquid-filled transformers depend heavily on oil quality for insulation and cooling. Analytical transformer testing equipment ensures fluid condition meets operational requirements.

| Oil Test Method | Equipment Used | Purpose | Maintenance Benefit |

|---|---|---|---|

| Breakdown voltage test | Portable oil tester | Measures dielectric strength | Confirms insulation capability |

| Moisture analysis | Karl Fischer titrator | Determines water content | Prevents insulation failure |

| Dissolved gas analysis | Gas chromatograph | Identifies fault gases | Early fault detection |

| Acidity measurement | Titration kit | Tracks oxidation level | Guides oil replacement planning |

Thermal imaging cameras also play a role, allowing engineers to identify overheating terminals or bushings while the transformer remains energized.

Know more about Power Quality Analyzer Buying Guide for Engineers

Practical Considerations When Selecting Equipment

Choosing suitable transformer testing equipment requires evaluation of several factors beyond measurement capability. Engineers must consider portability, data storage, automation level, and compatibility with existing asset management systems. Rugged construction and intuitive interfaces are valuable in harsh substation environments where reliability and efficiency matter.

Calibration support and compliance with recognized standards should guide purchasing decisions. Equipment that meets industry benchmarks ensures results remain credible during audits and regulatory reviews. Integration with digital reporting platforms further improves workflow by simplifying documentation and trend analysis.

Integration of Digital Technology in Diagnostics

Recent advancements have transformed transformer testing equipment into intelligent platforms capable of real-time analysis. Wireless connectivity allows instant sharing of results with engineering teams, while embedded software performs automatic corrections and comparisons with historical databases.

Know more about High Voltage Testing Procedures for Electrical Panels: Step by Step

Cloud-based storage solutions also enable predictive maintenance strategies. Instead of reacting to failures, utilities can analyze data trends and schedule targeted inspections. This digital shift not only reduces downtime but also improves asset utilization across complex energy networks.

Safety and Best Practices During Testing

Working with high-voltage assets demands strict adherence to safety procedures. Proper grounding, lockout protocols, and use of personal protective equipment are mandatory when deploying transformer testing equipment. Engineers should verify instrument ratings match the system voltage level and confirm calibration status before initiating any measurement.

Documentation is equally important. Recording environmental conditions, temperature adjustments, and connection configurations ensures results remain traceable and reproducible. Thorough reporting strengthens engineering decisions and enhances long-term reliability planning.

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

Future Outlook for Diagnostic Technologies

As power systems expand with renewable integration and smart grid adoption, diagnostic expectations continue to rise. Manufacturers are developing transformer testing equipment with enhanced sensitivity, automated interpretation, and integrated artificial intelligence support. These innovations aim to shorten testing cycles and deliver more accurate insights into asset condition.

Portable multi-function devices are also becoming common, reducing the need to transport multiple instruments to remote substations. Engineers benefit from streamlined workflows while maintaining diagnostic depth. Such developments suggest that condition-based maintenance supported by advanced analytics will define the next stage of transformer management.

Conclusion

Effective condition assessment depends on selecting and using transformer testing equipment that aligns with technical requirements and operational realities. From electrical resistance measurement to oil analysis and frequency response diagnostics, each tool contributes a piece to the overall health profile of a transformer. Power engineers who understand these instruments can detect faults early, maintain compliance with standards, and optimize asset longevity.

Find all about High Voltage Cable Testing Standards: Complete Guide for Engineers

A structured approach to diagnostics ensures that testing results translate into meaningful action rather than routine paperwork. By combining traditional measurement practices with modern digital capabilities, transformer testing equipment continues to evolve into an essential foundation for reliable power system operation.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerTestingEquipment, #PowerEngineering, #ElectricalTesting, #SubstationMaintenance, #HighVoltageTesting, #TransformerDiagnostics, #GridReliability, #ElectricalEngineers, #ConditionMonitoring, #EnergyInfrastructure