Transformer Testing and Commissioning Procedure: Best Professional Guide for Power System Engineers

A structured transformer testing and commissioning procedure is essential before any power transformer is energized in a utility, industrial, or renewable energy installation. Transformers are among the most critical assets in a power system, and their reliability directly affects system stability, equipment safety, and operational continuity. Engineers involved in substations, EPC projects, or plant expansion must understand each stage of the transformer testing and commissioning procedure to ensure compliance with standards, minimize risk, and confirm performance under real operating conditions.

Table of Contents

This guide explains the transformer testing and commissioning procedure in practical terms, covering inspection, pre-commissioning checks, electrical testing, and final energization practices. The discussion aligns with common field practices and international standards such as IEC and IEEE while remaining applicable to real project environments.

Importance of Transformer Testing and Commissioning

The transformer testing and commissioning procedure verifies that installation has been completed correctly and that the equipment performs according to design specifications. Transportation, storage, or installation issues can introduce insulation damage, moisture ingress, or mechanical stress. Without verification, such defects may remain hidden until a failure occurs.

A well-executed transformer testing and commissioning procedure helps engineers confirm insulation integrity, winding continuity, tap changer functionality, and protection coordination. It also provides baseline data for maintenance teams, allowing future condition monitoring through trend comparison. From a project management perspective, proper commissioning reduces warranty disputes and ensures contractual compliance before handover.

Pre-Commissioning Inspection Requirements

The first stage of any transformer testing and commissioning procedure begins with visual and mechanical inspection. This stage confirms that the equipment is installed according to drawings and manufacturer recommendations. Inspections typically include checking nameplate details, verifying rating compatibility with system voltage, and confirming correct earthing connections.

Engineers also inspect oil levels, silica gel condition, bushing surfaces, and gasket integrity. Mechanical accessories such as conservators, breather assemblies, marshalling boxes, and Buchholz relays must be examined for alignment and tightness. These early checks prevent unnecessary delays during electrical testing.

Table 1 shows a typical inspection checklist used in field projects.

Know more about What Provides Short Circuit Protection for the Motor

Table 1: Pre-commissioning visual inspection checklist

| Item | Verification Points | Expected Outcome |

|---|---|---|

| Nameplate data | Voltage ratio, vector group, rating | Matches design documents |

| Oil level | Conservator indicator reading | Within marked limits |

| Bushings | Cleanliness and cracks | No damage observed |

| Earthing | Tank and neutral grounding | Secure connection |

| Accessories | Fans, pumps, relays | Proper installation |

| Cable termination | Tightness and labeling | Correct phasing |

Completing these steps strengthens the overall transformer testing and commissioning procedure by ensuring readiness for electrical testing.

Electrical Tests Before Energization

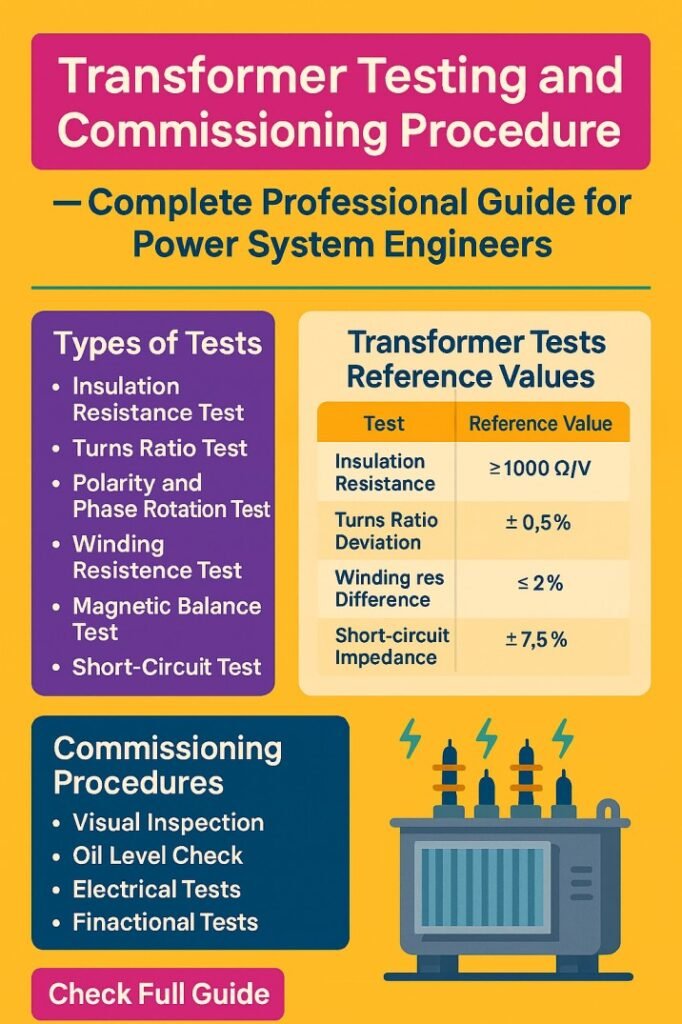

Electrical testing forms the technical core of the transformer testing and commissioning procedure. These tests evaluate insulation strength, winding condition, and connection accuracy. Results must be compared against manufacturer data or standard limits.

Common tests are summarized below.

Know more about Fault Current and Short Circuit Current: A Quick Guide

Table 2: Standard electrical tests

| Test Name | Purpose | Key Observation |

|---|---|---|

| Insulation Resistance | Assess insulation quality | High resistance value |

| Turns Ratio | Verify winding ratio accuracy | Matches rated ratio |

| Winding Resistance | Detect loose connections | Balanced readings |

| Vector Group | Confirm phase displacement | Correct configuration |

| Magnetizing Current | Check core condition | Stable current |

| Dielectric Tests | Validate insulation strength | No breakdown |

Each of these measurements contributes to the transformer testing and commissioning procedure by building confidence in equipment health before energization.

Insulation resistance testing is often performed using a megohmmeter, and results are temperature corrected for accurate comparison. Turns ratio testing confirms winding configuration, which is critical for parallel operation and protection coordination. Winding resistance measurement helps identify contact issues within tap changers or joints. Together, these steps ensure that the transformer testing and commissioning procedure captures both electrical and mechanical concerns.

Oil Quality and Dielectric Assessment

Oil-filled transformers require additional analysis as part of the transformer testing and commissioning procedure. Oil acts as both insulation and coolant, so its condition directly affects performance. Samples are typically collected and tested for breakdown voltage, moisture content, acidity, and dissolved gases.

Know more about What is the Maximum Value for Short Circuit Protection for Multi-Motor Branch Circuits

Engineers performing the transformer testing and commissioning procedure review laboratory results to confirm acceptable dielectric strength. Poor results may require filtration or replacement before energization. Monitoring oil parameters during commissioning establishes baseline values for future diagnostics, which is particularly valuable for predictive maintenance strategies.

Functional Checks of Protection and Control Systems

Beyond primary equipment tests, the transformer testing and commissioning procedure must include functional verification of protection and monitoring systems. Protection schemes ensure rapid isolation during faults and prevent catastrophic damage.

Typical functional checks include verifying relay settings, testing alarm contacts, and simulating trip conditions. Communication links with supervisory control systems should also be confirmed. Cooling systems such as forced air or oil circulation must be operated to verify automatic response.

Table 3 outlines typical functional checks.

Know more about Short Circuit Calculation Methods: IEC vs ANSI

Table 3: Protection and auxiliary system checks

| System | Check Performed | Result Expected |

|---|---|---|

| Differential protection | Injection test | Correct trip action |

| Buchholz relay | Alarm simulation | Signal received |

| Temperature indicators | Calibration check | Accurate display |

| Cooling fans | Auto start test | Proper operation |

| Control wiring | Continuity test | Reliable signal path |

Including these tasks ensures the transformer testing and commissioning procedure evaluates not only hardware condition but also operational readiness.

Final Energization Preparation

Before energizing the transformer, engineers review documentation generated throughout the transformer testing and commissioning procedure. Test reports, inspection records, and calibration certificates must be compiled and approved. Clearance from protection teams and grid operators is also required.

Use our online tool Short Circuit Current Calculator: Best Tool

At this stage, terminals are rechecked for tightness, safety barriers are installed, and communication with operations personnel is established. Energization is usually performed gradually while monitoring inrush current, noise levels, and temperature rise. Any abnormal vibration or protection response requires immediate shutdown and investigation.

Executing energization carefully completes the transformer testing and commissioning procedure and transitions the equipment into operational service.

Documentation and Reporting Practices

Proper documentation strengthens the value of the transformer testing and commissioning procedure. Records should include raw data, corrected readings, calibration references, and environmental conditions during testing. Engineers should maintain structured logs so maintenance teams can track aging patterns or insulation degradation later.

Well-organized documentation also supports regulatory compliance and insurance validation. Many utilities consider documentation an essential deliverable of the transformer testing and commissioning procedure, not merely an administrative step.

Practical Considerations for Field Engineers

Field conditions often influence how the transformer testing and commissioning procedure is carried out. Weather, access limitations, and resource availability can affect scheduling. Engineers should plan equipment calibration, ensure safety permits are active, and maintain clear communication with construction teams.

Use our online tool Short Circuit Current Calculator for Motors: Best Tool

Safety remains central throughout the transformer testing and commissioning procedure. Lockout practices, personal protective equipment, and proper grounding are mandatory. These precautions protect personnel while preserving equipment integrity.

Another practical aspect involves coordination with related equipment commissioning, such as switchgear or cable systems. Integrating these activities allows the transformer testing and commissioning procedure to align with overall system readiness, avoiding repetitive outages or delays.

Conclusion

A thorough transformer testing and commissioning procedure ensures that transformers enter service safely and reliably. From visual inspection and electrical verification to protection checks and documentation, each stage contributes to confirming operational integrity. Engineers who follow a structured transformer testing and commissioning procedure reduce risk, improve system dependability, and create valuable performance benchmarks for future maintenance.

Use our onkline tool Transformer Short Circuit Calculator – Accurate Fault Current & Transformer Protection Tool

For power system engineers working in substations, industrial facilities, or renewable installations, mastering the transformer testing and commissioning procedure is not just a technical requirement. It is a professional responsibility that directly influences safety, efficiency, and asset longevity. By applying disciplined testing methods, maintaining accurate records, and observing safety standards, engineers ensure that transformers perform as intended throughout their service life.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerTesting, #CommissioningProcedure, #ElectricalEngineering, #PowerSystems, #SubstationTesting, #HighVoltageTesting, #EngineeringStandards, #ElectricalMaintenance, #GridReliability, #IndustrialPower