Transformer Size and Frequency Relation | Professional Engineering Guide for Efficient Power System Design

Understanding the transformer size and frequency relation is essential for engineers who work on power system planning, equipment selection, or electrical infrastructure upgrades. Transformer dimensions, core mass, copper utilization, and thermal performance are closely tied to operating frequency. Whether designing a grid substation, specifying a distribution unit, or selecting equipment for industrial loads, mastering this principle ensures efficiency, cost control, and reliable service life.

Table of Contents

Transformers operate on electromagnetic induction, where voltage is linked to magnetic flux in the core. Frequency directly affects how magnetic flux develops, which in turn influences core area and winding turns. A clear grasp of the transformer size and frequency relation helps professionals make informed decisions when adapting equipment between regions or evaluating alternatives for renewable integration.

Fundamentals of Magnetic Flux and Frequency

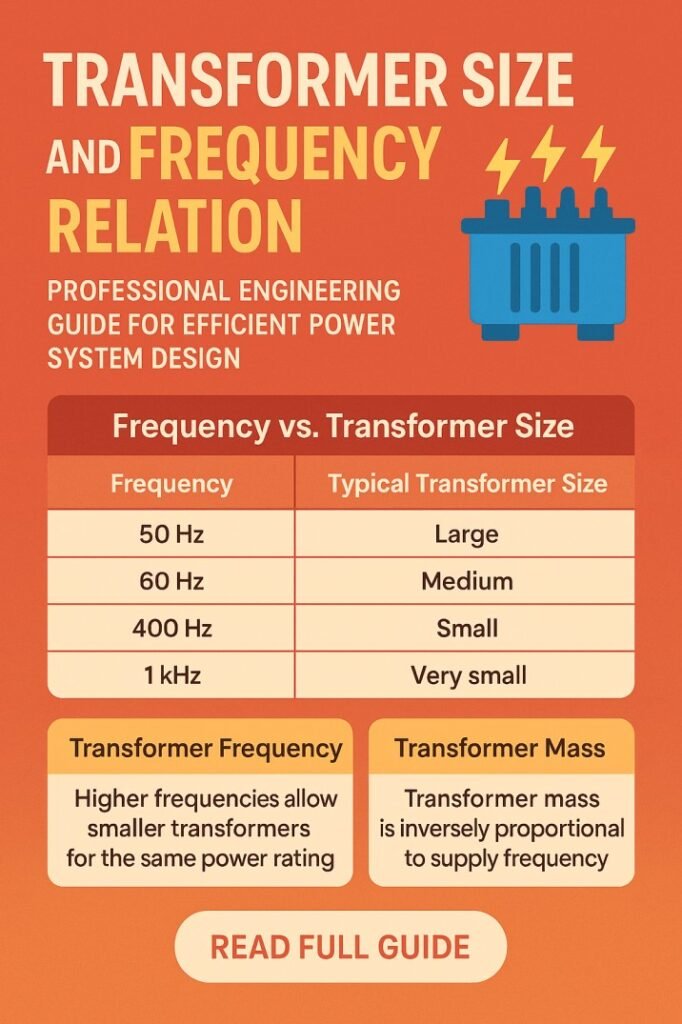

Transformer voltage can be expressed through the familiar equation relating induced voltage, frequency, and flux density. When frequency increases, the same voltage can be achieved with lower flux per cycle. This reduces the required core cross-section and material volume. Conversely, at lower frequency, flux must rise to maintain voltage, which demands a larger core and heavier construction.

Start using our online tool today — it’s free Transformer Short Circuit Calculator – Accurate Fault Current & Transformer Protection Tool

From an engineering standpoint, the transformer size and frequency relation shows that core dimensions scale inversely with operating frequency. Systems running at 60 Hz typically allow smaller and lighter transformers compared to equivalent ratings at 50 Hz. At very low frequencies, such as railway traction or specialized industrial applications, transformers become significantly bulkier due to magnetic saturation limits.

Key practical points include stable flux density limits, insulation considerations, and heat dissipation capability. These aspects ensure the equipment meets efficiency and life expectancy targets while complying with industry standards.

Core Design and Material Utilization

Magnetic core selection reflects the transformer size and frequency relation in tangible design parameters. Silicon steel laminations, grain-oriented steel, and amorphous alloys are chosen based on loss characteristics and mechanical constraints. Higher frequency reduces core size but increases hysteresis and eddy current losses if materials are not optimized.

Test our online tool for free Transformer Full Load Current Calculator – Accurate Load & Current Calculation Tool for Transformers

Engineers often evaluate these factors during specification. Core area, window space, and stacking factor must balance electrical loading and thermal limits. The table below illustrates the general trend between frequency and size impact for similar power ratings.

| Frequency (Hz) | Relative Core Size | Weight Trend | Typical Application |

|---|---|---|---|

| 16.7 | Very Large | Very Heavy | Railway traction systems |

| 25 | Large | Heavy | Legacy industrial networks |

| 50 | Standard | Moderate | Europe, Asia distribution grids |

| 60 | Smaller | Lower | North America power systems |

| 400 | Very Small | Very Light | Aerospace and military systems |

These comparisons highlight how the transformer size and frequency relation influences physical layout, transportation planning, and installation cost.

Enjoy free access to our online tool Step-Down Transformer Calculator – Accurate Voltage & Power Conversion Tool

Copper Windings and Thermal Behavior

Winding design also reflects frequency dependency. Higher frequency enables fewer turns for the same voltage, reducing copper length and resistance losses. This can improve efficiency and reduce temperature rise under load. However, skin effect and proximity effect become more pronounced as frequency climbs, requiring stranded conductors or special winding geometry.

Thermal management is equally important. Reduced size at higher frequency concentrates heat in a smaller volume. Cooling ducts, oil circulation, or forced air systems must compensate for this concentration. Engineers analyzing the transformer size and frequency relation often evaluate load profile, ambient temperature, and insulation class to ensure safe operation.

Use our online tool without paying anything Transformer Impedance Calculation Tool – Accurate Transformer Impedance Calculator for Engineers

Efficiency, Losses, and System Optimization

Efficiency calculations must consider both copper and core losses across frequency ranges. While smaller cores lower material costs, higher frequency can increase specific loss components. Designers must weigh capital expense against operational efficiency.

A simplified comparison of performance trends is shown below.

| Parameter | Low Frequency Operation | High Frequency Operation |

|---|---|---|

| Core Volume | Increased | Reduced |

| Copper Turns | Higher | Lower |

| Magnetizing Current | Higher | Lower |

| Eddy Current Loss | Lower | Higher |

| Transport and Installation | Complex | Easier |

Such evaluations guide project engineers toward balanced designs that satisfy electrical demand and economic constraints.

Get started with our free online tool Transformer Efficiency Calculator – Calculate Power, Losses & Performance Instantly

Practical Engineering Applications

The transformer size and frequency relation becomes especially relevant when equipment is transferred between systems of different frequencies. Operating a 60 Hz transformer on 50 Hz without derating may lead to saturation and overheating. Conversely, using a 50 Hz transformer on 60 Hz is generally acceptable but may not deliver optimal cost efficiency.

Renewable energy integration, inverter-based generation, and aviation power networks further emphasize the importance of frequency-dependent sizing. Variable frequency environments require adaptable magnetic designs and careful harmonic evaluation. In large substations, transport limitations and foundation requirements also tie directly to equipment size driven by frequency considerations.

Access our online tool completely free Transformer Vector Group Calculation Tool | Easy & Accurate Vector Group Calculator

Design Considerations for Specification Engineers

Professionals specifying transformers must examine voltage class, load factor, ambient environment, and system frequency together rather than in isolation. The transformer size and frequency relation interacts with short-circuit strength, insulation coordination, and mechanical stability.

Important specification checkpoints include verifying rated frequency alignment, assessing derating factors for mismatch conditions, and reviewing manufacturer loss data. Consulting detailed test certificates and type test reports ensures compliance with performance expectations and regulatory frameworks.

Conclusion

A thorough understanding of the transformer size and frequency relation provides a strong technical foundation for efficient power system design. Frequency shapes magnetic flux behavior, core dimensions, winding construction, and heat management strategies. By accounting for these interactions, engineers can select equipment that balances performance, durability, and cost effectiveness.

Use our tool online at no cost Transformer Losses Calculation Tool – Accurate & Easy Energy Loss Analysis

In modern infrastructure planning, where interconnection, renewable expansion, and efficiency targets dominate decision making, applying the transformer size and frequency relation correctly leads to reliable operation and optimized lifecycle value. Mastery of this concept remains a practical necessity for professionals committed to delivering resilient and efficient electrical networks. Try our free online tool Transformer Temperature Rise Calculator: Accurate and Easy Guide

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerDesign, #PowerEngineering, #ElectricalEngineering, #FrequencyRelation, #TransformerSize, #EnergySystems, #VoltageControl, #GridTechnology, #EngineeringInsights, #PowerDistribution