Transformer Differential Protection Testing | Professional Guide to Methods, Tools & Relay Performance Verification

Transformer differential protection testing is a critical activity in maintaining the stability and reliability of modern power systems. Power transformers represent high-value assets, and their failure can lead to prolonged outages, safety risks, and financial losses. For that reason, transformer differential protection testing is performed to confirm that relays operate correctly under internal fault conditions while remaining stable during normal load, external faults, and magnetizing inrush.

Table of Contents

This guide explains practical methods, commonly used tools, and professional approaches for relay performance verification. It is written from a field engineering perspective and focuses on procedures that improve accuracy, minimize downtime, and ensure compliance with commissioning and maintenance standards.

Understanding the Purpose of Transformer Differential Protection Testing

Differential protection compares current entering and leaving the transformer windings. Any imbalance beyond the defined restraint characteristics indicates a possible internal fault such as winding insulation failure, phase-to-phase faults, or turn-to-turn short circuits. Transformer differential protection testing verifies that the protective scheme detects these conditions without false tripping.

Start using our online tool today — it’s free Transformer Short Circuit Calculator – Accurate Fault Current & Transformer Protection Tool

During commissioning or periodic maintenance, transformer differential protection testing confirms CT polarity, vector group compensation, slope characteristics, and zero sequence filtering. Engineers rely on these checks to ensure the relay settings match transformer nameplate data and system configuration. Proper verification prevents nuisance operations and ensures rapid isolation when actual faults occur.

Key Principles Behind Relay Operation

Before carrying out transformer differential protection testing, it is important to understand the underlying relay logic. Differential relays operate on restraint and operate current comparison. They apply percentage bias or dual slope characteristics to distinguish internal faults from external disturbances.

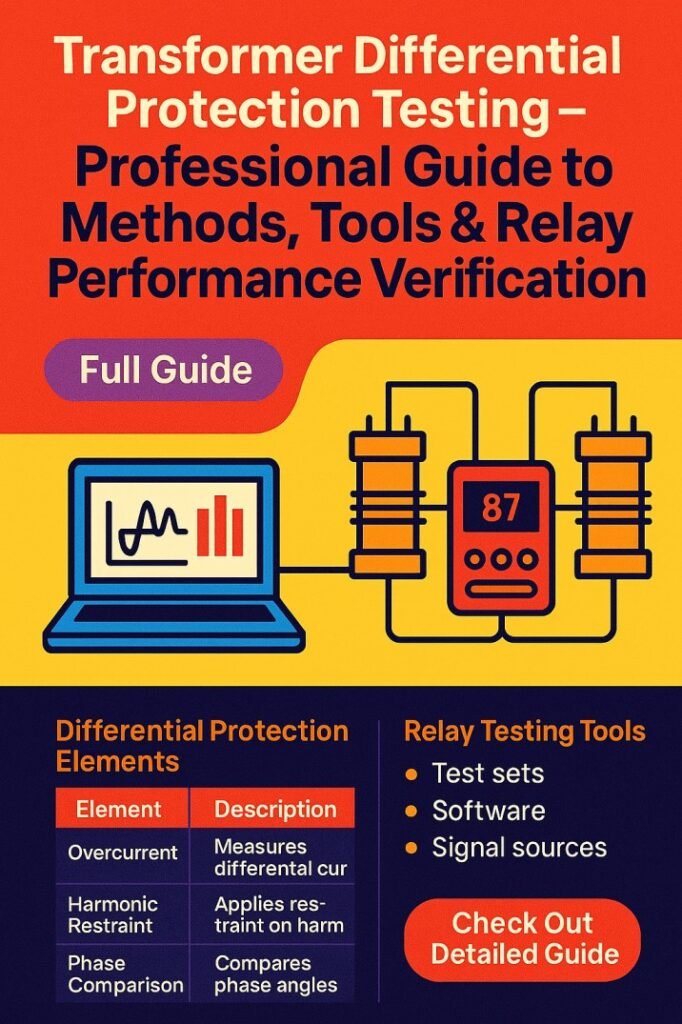

Important relay elements evaluated during transformer differential protection testing include:

- Differential pickup current

- Bias slope settings

- Harmonic restraint or blocking

- Zero sequence compensation

- Vector group phase shift alignment

These parameters collectively determine sensitivity and stability. Testing them confirms coordination with upstream and downstream protection schemes.

Test our online tool for free Transformer Full Load Current Calculator – Accurate Load & Current Calculation Tool for Transformers

Common Testing Methods Used by Professionals

Different stages of a transformer lifecycle require distinct approaches to transformer differential protection testing. Field engineers typically adopt a structured sequence that starts with wiring validation and ends with dynamic relay evaluation.

Primary Injection Method

Primary injection verifies the entire protection path from CTs to relay input. High current is injected through primary conductors to simulate real operating conditions. This form of transformer differential protection testing confirms CT ratio correctness, wiring integrity, and polarity.

Advantages include realistic system verification, but it requires higher power sources and safety planning.

Secondary Injection Method

Secondary injection is widely used because it allows precise control of current magnitude and phase angle. By injecting current directly into the relay terminals, technicians assess operating thresholds, slope response, and timing.

Enjoy free access to our online tool Step-Down Transformer Calculator – Accurate Voltage & Power Conversion Tool

This approach to transformer differential protection testing offers repeatability and efficiency, especially when using automated relay test sets.

Simulation Based Functional Testing

Modern digital relays support advanced scenario simulation. Engineers use specialized software with testing equipment to model internal faults, through faults, and inrush conditions. Functional transformer differential protection testing ensures logic algorithms behave as expected under multiple operating states.

The following table summarizes the comparison of testing approaches.

| Testing Method | Application Stage | Key Benefits | Limitations |

|---|---|---|---|

| Primary Injection | Commissioning | Validates full current path | Requires heavy equipment |

| Secondary Injection | Maintenance | Accurate and flexible | Does not test CTs fully |

| Simulation Testing | Advanced verification | Evaluates logic response | Needs skilled setup |

Use our online tool without paying anything Transformer Impedance Calculation Tool – Accurate Transformer Impedance Calculator for Engineers

Tools Required for Effective Testing

Professional transformer differential protection testing depends on reliable measurement instruments and calibrated equipment. Selection of tools influences both test accuracy and time efficiency.

Common equipment used includes:

| Tool | Purpose | Importance in Testing |

|---|---|---|

| Relay Test Set | Current and voltage injection | Core testing device |

| Clamp Meter | Current verification | Quick measurement checks |

| Insulation Tester | Wiring insulation validation | Ensures safety |

| Phase Angle Meter | Vector confirmation | Detects wiring errors |

| Laptop with Software | Configuration and analysis | Enables detailed evaluation |

Digital multi-phase test sets are particularly useful because they allow synchronized current injection, harmonic simulation, and automated reporting. Their integration into transformer differential protection testing workflows significantly reduces human error.

Get started with our free online tool Transformer Efficiency Calculator – Calculate Power, Losses & Performance Instantly

Step by Step Professional Testing Workflow

A systematic approach ensures consistent outcomes during transformer differential protection testing. Experienced engineers typically follow these stages.

Visual Inspection and Documentation Review

Nameplate data, protection settings, and wiring diagrams are reviewed before energizing equipment. Any mismatch between design and configuration must be resolved.

Polarity and Continuity Check

Verifying CT polarity and wiring continuity is essential. Incorrect polarity may produce false differential currents and lead to misoperation.

Relay Configuration Verification

Settings such as vector group compensation and slope values are compared against design calculations. Transformer differential protection testing at this stage confirms configuration accuracy.

Functional Injection Testing

Controlled current injection simulates fault conditions. Pickup values, restraint behavior, and trip outputs are recorded and analyzed.

Access our online tool completely free Transformer Vector Group Calculation Tool | Easy & Accurate Vector Group Calculator

Result Evaluation and Reporting

Measured data is compared with expected values. Detailed reports ensure traceability and support future maintenance planning.

Relay Performance Verification Parameters

Performance evaluation during transformer differential protection testing focuses on measurable indicators. These parameters confirm relay sensitivity and reliability.

| Parameter | Expected Outcome | Testing Objective |

|---|---|---|

| Pickup Accuracy | Within tolerance | Confirm sensitivity |

| Operating Time | Meets design criteria | Validate speed |

| Stability | No trip during through faults | Ensure security |

| Harmonic Restraint | Blocks inrush tripping | Prevent nuisance trips |

| Vector Matching | Correct phase shift handling | Guarantee accuracy |

Consistent monitoring of these parameters strengthens confidence in protection system dependability.

Challenges Encountered During Field Testing

Transformer differential protection testing in operational environments often involves practical challenges. Space limitations, energized adjacent equipment, and time constraints may complicate procedures. Engineers must also account for electromagnetic interference and instrument calibration drift.

Use our tool online at no cost Transformer Losses Calculation Tool – Accurate & Easy Energy Loss Analysis

Another challenge lies in interpreting results where CT saturation or wiring inconsistencies affect readings. Careful planning and cross verification help maintain testing accuracy. Applying best practices and documenting observations improves reliability over successive maintenance cycles.

Best Practices for Reliable Results

Experienced professionals adopt certain habits that enhance the effectiveness of transformer differential protection testing. These include maintaining calibration records, validating test leads before connection, and ensuring proper grounding.

Consistent labeling and organized data storage streamline troubleshooting. Engineers also prefer automated test sequences where possible, as they reduce manual variability and provide standardized documentation. These practices contribute to improved system resilience and regulatory compliance.

Importance of Periodic Testing in Asset Management

Routine transformer differential protection testing supports long term asset management strategies. Utilities and industrial operators rely on scheduled verification to detect hidden issues before they escalate. Preventive maintenance aligned with operational cycles ensures protection reliability during peak loading periods.

Try our free online tool Transformer Temperature Rise Calculator: Accurate and Easy Guide

Data collected from transformer differential protection testing also feeds into predictive maintenance analytics. Trending pickup deviations or timing changes helps identify aging components and guides refurbishment planning. This proactive approach reduces unexpected outages and improves return on infrastructure investment.

Conclusion

Transformer differential protection testing remains a cornerstone of power system reliability. By confirming relay sensitivity, stability, and configuration accuracy, engineers protect critical transformer assets from severe internal faults. Combining primary injection, secondary injection, and advanced simulation techniques ensures comprehensive coverage across commissioning and maintenance stages.

Using calibrated tools, structured workflows, and careful documentation allows transformer differential protection testing to deliver dependable results. When carried out regularly and interpreted correctly, it strengthens operational safety, minimizes downtime, and preserves the integrity of electrical networks. As systems evolve toward digital substations and intelligent monitoring, transformer differential protection testing will continue to play an essential role in safeguarding modern power infrastructure.

Use our online tool for free Transformer Neutral Current Calculator – Accurate Neutral Current Estimation

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerDifferentialProtection, #ProtectionTesting, #PowerSystemProtection, #RelayTesting, #ElectricalEngineering, #SubstationTesting, #ProtectionRelay, #TransformerMaintenance, #GridReliability, #ElectricalTesting