Sub Panel Neutral and Ground on Same Bus Bar – Code Rules, Risks & Correct Wiring Explained

The topic sub panel neutral and ground on same bus bar creates confusion for many electricians, homeowners, and engineers. Mistakes in subpanel wiring are common, and most of them revolve around misunderstanding how neutral and ground conductors should be handled. This article explains the electrical code rules, real-world risks, and correct wiring practices in a practical, easy-to-follow manner while keeping safety and compliance as the priority.

Table of Contents

Understanding why neutral and ground separation matters in a subpanel can prevent shock hazards, nuisance tripping, and inspection failures. Whether you are upgrading a panel, adding a workshop subpanel, or reviewing an existing installation, this guide will give you clarity.

Understanding Neutral and Ground in Electrical Systems

Neutral and ground conductors serve different purposes, even though they are connected at one point in the electrical system. The neutral carries return current during normal operation. The equipment grounding conductor carries current only during a fault condition.

In the main service panel, neutral and ground are bonded together. This is the only location where bonding is allowed. Once power is distributed to downstream panels, separation becomes mandatory.

The confusion around sub panel neutral and ground on same bus bar usually comes from applying main panel rules to subpanels, which is incorrect.

Use our online tool for free Sub Panel Breaker Size Calculator – Find the Right Breaker for Your Electrical Sub Panel

Electrical Code Rules for Subpanels

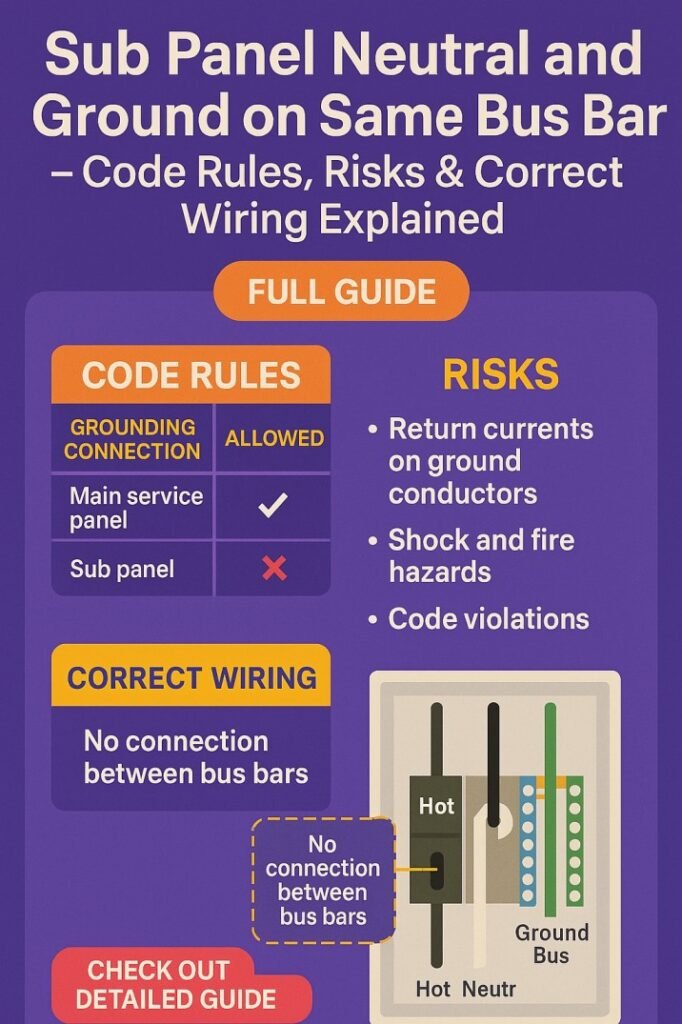

Electrical codes such as the NEC clearly define how neutral and ground conductors must be installed in a subpanel. The rules are consistent across residential, commercial, and industrial installations.

Key code requirements include:

- Neutral bus must be isolated from the panel enclosure

- Ground bus must be bonded to the panel enclosure

- Neutral and ground must not be connected together in a subpanel

- A four-wire feeder is required (hot, hot, neutral, ground)

These rules exist to ensure fault current returns safely without energizing metal parts.

Main Panel vs Subpanel Comparison

| Feature | Main Service Panel | Sub Panel |

|---|---|---|

| Neutral bonded to ground | Yes | No |

| Neutral bus isolated | No | Yes |

| Ground bus bonded to enclosure | Yes | Yes |

| Number of feeder conductors | 3 or 4 | 4 |

This table highlights why copying main panel wiring into a subpanel is unsafe.

Use our online tool for free Sub Panel Wire Size Calculator – Accurate Wire Gauge & Load Sizing Tool

Why Neutral and Ground Must Be Separate in a Subpanel

When sub panel neutral and ground on same bus bar is done incorrectly, neutral current flows onto grounding paths. This creates several serious problems.

Neutral current on grounding conductors can:

- Energize metal conduits and enclosures

- Create shock hazards on equipment frames

- Interfere with GFCI and AFCI devices

- Cause erratic voltage readings

- Increase corrosion in metallic systems

Ground conductors should remain current-free during normal operation. Mixing them defeats their safety function.

Real Risks of Bonding Neutral and Ground in a Subpanel

Improper bonding is not just a code violation. It is a safety issue with real consequences.

Common risks include:

- Electric shock when touching metal enclosures

- Failure of overcurrent protection to clear faults

- Nuisance tripping of breakers

- Increased risk of fire due to stray currents

- Failed electrical inspections and insurance issues

Use our online tool for free Sub Panel Sizing Calculator: Best Tool to Use

In wet locations such as garages, basements, and outdoor panels, the danger becomes even higher.

Common Wiring Mistakes in Subpanels

Many installations fail due to simple errors that are easy to avoid once understood.

Typical mistakes include:

- Installing bonding screw in a subpanel neutral bar

- Using a three-wire feeder instead of four-wire

- Landing ground wires on the neutral bus

- Failing to install a separate ground bar

- Assuming neutral-ground bonding improves safety

Each of these mistakes contributes to the sub panel neutral and ground on same bus bar problem.

Correct Wiring Method for a Subpanel

Correct wiring follows a clear and repeatable process. When done properly, the subpanel operates safely and passes inspection.

Correct steps include:

- Run a four-wire feeder from the main panel

- Connect neutral conductor to an isolated neutral bus

- Install a separate ground bus bonded to the enclosure

- Remove any bonding screw or strap from neutral bar

- Terminate all grounding conductors on the ground bus

Use our online tool for free Wire Size Calculator for Subpanels and Feeders – NEC Guidelines Included

Proper Subpanel Wiring Overview

| Component | Correct Connection |

|---|---|

| Neutral feeder | Isolated neutral bus |

| Ground feeder | Ground bus bonded to enclosure |

| Branch neutrals | Neutral bus only |

| Branch grounds | Ground bus only |

| Bonding screw | Not installed |

This setup ensures fault currents return safely without using unintended paths.

Special Cases and Exceptions

Some older installations may have three-wire feeders feeding subpanels. These were allowed under older code editions but are no longer permitted for new installations.

In existing systems:

- Neutral-ground bonding may be present but not ideal

- Upgrading requires adding a separate grounding conductor

- Local authority rules may require correction

Detached structures like garages often require ground rods in addition to proper conductor separation.

Know more about Industrial Control Panel Design Software – Best Tools, Features & Pro Tips for Engineers

Grounding Electrodes and Subpanels

Ground rods do not replace the equipment grounding conductor. A ground rod stabilizes voltage but does not carry fault current effectively.

Important points:

- Subpanels in detached buildings usually require ground rods

- Ground rods do not justify bonding neutral and ground

- Equipment grounding conductor is always required

Misunderstanding grounding electrodes often leads back to the sub panel neutral and ground on same bus bar misconception.

Inspection and Troubleshooting Tips

If you are inspecting or troubleshooting a subpanel, a few checks can quickly identify issues.

Checklist:

- Verify neutral bus is insulated from enclosure

- Check for bonding screw presence

- Measure voltage between neutral and ground

- Inspect feeder cable for four conductors

- Confirm grounding bar is properly bonded

These steps help detect unsafe bonding before it causes problems.

Use our online tool for free Electrical Panel Upgrade Cost Calculator: Best Tool

Frequently Asked Questions

Can neutral and ground be on the same bar in a subpanel?

No. Neutral and ground must remain separate in a subpanel to prevent shock hazards and comply with code.

Why is bonding allowed only at the main panel?

Bonding at a single point ensures fault current has a predictable path and prevents circulating currents.

What happens if neutral and ground are mixed?

Mixing creates parallel current paths and energizes grounded metal parts, increasing risk.

Final Thoughts

The rule against sub panel neutral and ground on same bus bar is one of the most important principles in electrical distribution. It exists to protect people, equipment, and property. While the wiring may look simple, the consequences of getting it wrong can be severe.

By following code rules, understanding the risks, and applying correct wiring practices, subpanels can operate safely for decades. Proper separation of neutral and ground is not just a technical requirement. It is a fundamental safety practice that every electrical installation must respect.

Know more about IEC Standard for Busbar Clearance

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#SubPanelWiring,#NeutralAndGround,#ElectricalCode,#PanelBoard,#GroundingSystem,#ElectricalSafety,#NECCompliance,#HomeWiring,#ElectricalEngineering,#SubPanelInstallation