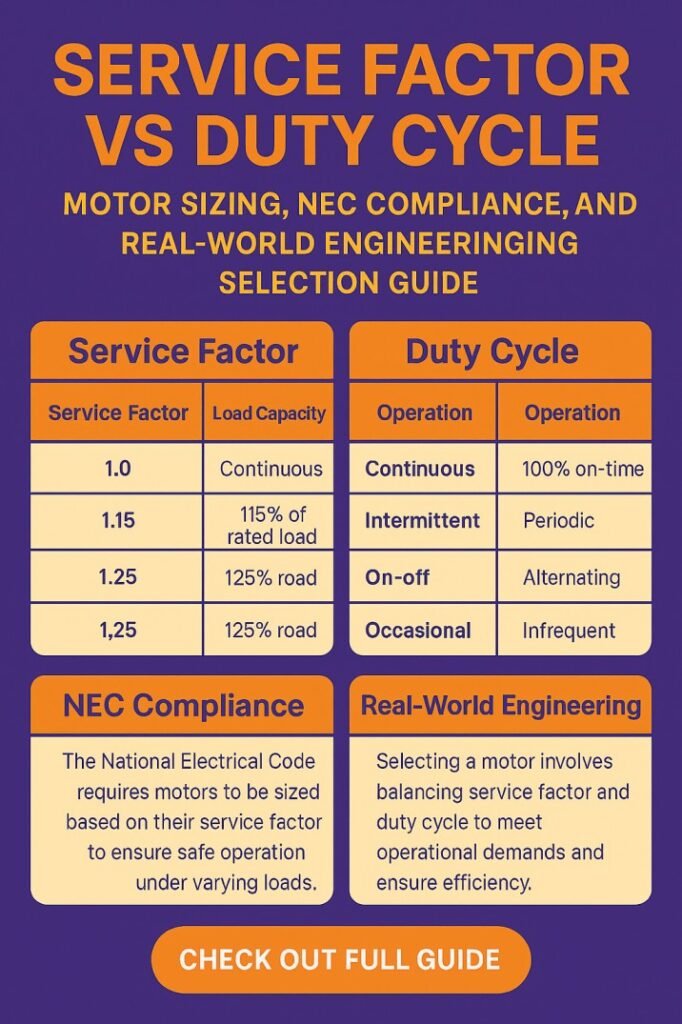

Service Factor vs Duty Cycle: Motor Sizing, NEC Compliance, & Best Engineering Selection Guide

Understanding service factor vs duty cycle is essential for correct motor sizing, thermal protection, and long-term reliability. These two terms are often confused, yet they describe very different aspects of motor operation. One relates to how much extra load a motor can safely handle, while the other defines how long and how often the motor runs. When engineers misunderstand service factor vs duty cycle, the result is overheating, nuisance tripping, reduced insulation life, and costly downtime.

Table of Contents

This guide explains service factor vs duty cycle in practical engineering terms, links both to NEC compliance, and shows how to make smart motor selection decisions in real installations.

What Service Factor Really Means

Service factor is a multiplier assigned by the motor manufacturer that indicates how much load above the nameplate rating the motor can carry under specific conditions. A motor with a 1.15 service factor can operate at 115% of rated load without immediate damage, provided voltage, frequency, and ambient temperature stay within limits.

Service factor vs duty cycle confusion often begins here. Service factor is not intended for continuous overload operation. It is a design margin to handle occasional variations such as:

- Voltage fluctuations

- Short-term mechanical overload

- Higher than expected friction

- Minor process upsets

Know more about How to Wire a 480/277 Lighting System: Step-By-Step Guide for Safe Commercial Installation

Running continuously in the service factor range increases winding temperature and shortens insulation life. NEMA MG-1 makes it clear that service factor is a thermal reserve, not a standard operating point.

Service Factor and Heat Rise

Motor heating follows an exponential thermal curve. Even a small increase in load produces a significant rise in temperature. Using service factor continuously may push the motor beyond its insulation class thermal limit, even if current appears acceptable.

| Parameter | Rated Load Operation | Service Factor Operation |

|---|---|---|

| Torque | 100% | Up to 115% typical |

| Current | Nameplate FLA | Higher than FLA |

| Temperature Rise | Within design class | Elevated, reduced life |

| Efficiency | Optimal | Reduced |

| Insulation Life | Normal | Shortened |

This is why service factor vs duty cycle must be evaluated together during motor selection.

Know more about Difference Between Relay and Contactor: 7 Powerful Reasons This Guide Makes It Easy

What Duty Cycle Actually Defines

Duty cycle describes the pattern of motor operation over time. It indicates whether the motor runs continuously, intermittently, or in repeating cycles of load and rest. Unlike service factor, duty cycle focuses on time and thermal recovery, not overload margin.

IEC and NEMA classify duty cycles differently, but the thermal principle is the same: motors heat up under load and cool down when stopped or lightly loaded.

Common duty types include:

- Continuous duty (S1): Runs at constant load long enough to reach thermal equilibrium

- Short-time duty (S2): Runs for a limited time, then cools completely

- Intermittent periodic duty (S3): Repeating cycles of load and rest

- Continuous duty with electric braking (S5)

- Variable load duty (S6, S9)

When discussing service factor vs duty cycle, remember that duty cycle determines the thermal profile, while service factor defines load margin.

Use our online tool Kirchhoffs Law Calculator: Instantly Solve KCL & KVL Circuits Online

Why Engineers Mix Up Service Factor vs Duty Cycle

In real plants, motors rarely run at perfect steady loads. Pumps cycle, compressors unload, and conveyors surge. Engineers may rely on service factor to handle these variations, when the real issue is an intermittent or cyclic duty profile.

For example, a crusher motor that runs 30 seconds loaded and 30 seconds idle is not a continuous duty application. Applying service factor alone will not solve overheating if the duty cycle causes repeated thermal peaks.

Correct interpretation of service factor vs duty cycle prevents oversizing and undersizing at the same time.

NEC Compliance and Motor Sizing

The National Electrical Code treats motor protection conservatively. NEC Article 430 requires branch circuit conductors and protection devices to be sized based on nameplate full-load current, not service factor current.

Key NEC considerations include:

- Overload protection is typically set at 115% to 125% of nameplate FLA depending on service factor and temperature rise

- Conductors are sized at 125% of FLA for continuous duty motors

- Service factor does not permit smaller conductors or protection

| NEC Element | Based On | Affected by Service Factor? |

|---|---|---|

| Branch Conductors | 125% of FLA | No |

| Short Circuit Protection | Tables 430.52 | No |

| Overload Protection | 115–125% FLA | Yes, setting adjustments |

| Motor Rating | Nameplate HP | No |

Service factor vs duty cycle plays a role mainly in overload relay settings and thermal modeling, not feeder sizing.

Know more about Power Factor vs Crest Factor: Important Differences & Comparison

Thermal Modeling in Real Installations

Modern motor protection relays use thermal capacity models. These models simulate heating based on current over time. Here duty cycle becomes more important than service factor of Motor.

If a motor operates in a heavy cyclic duty, the relay must be programmed for that pattern. Otherwise, nuisance trips or overheating may occur.

Service factor vs duty cycle analysis helps determine:

- Trip class selection

- Restart delay time

- Thermal memory reset

- Need for RTDs or embedded thermistors

Ignoring duty cycle while relying on service factor is one of the most common causes of premature motor failure.

Practical Motor Selection Scenarios

Scenario 1: Centrifugal Pump

A water pump runs 24 hours a day with small flow variations. This is continuous duty. Service factor can cover minor hydraulic changes, but the motor should be sized close to actual load.

Best practice:

- Select motor with 1.15 service factor

- Size near 100% load at duty point

- Use VFD for flow control

Here service factor vs duty cycle analysis shows that duty is constant, so thermal reserve should not be the primary design tool.

Know more about What is Demand Factor and Diversity Factor? Quick Concepts

Scenario 2: Reciprocating Compressor

This compressor cycles between loaded and unloaded states. Average load is 70%, but torque spikes during loading.

Best practice:

- Evaluate torque peaks

- Choose motor with adequate service factor

- Confirm duty cycle allows cooling during unloaded periods

Service factor vs duty cycle balance ensures the motor survives starting and loading shocks without overheating.

Scenario 3: Conveyor with Start-Stop Operation

A packaging conveyor runs 2 minutes on, 3 minutes off.

Best practice:

- Treat as intermittent duty

- Check starting frequency limits

- Service factor less critical than thermal cycling capability

In this case, duty cycle drives selection more than service factor.

Comparing Service Factor and Duty Cycle

| Feature | Service Factor | Duty Cycle |

|---|---|---|

| Defines | Overload capability | Operating time pattern |

| Focus | Load margin | Heating and cooling cycles |

| Set By | Manufacturer | Application requirement |

| Affects | Temperature rise | Thermal equilibrium |

| NEC Impact | Overload settings | Conductor sizing for continuous loads |

| Common Misuse | Used as continuous rating | Ignored in cyclic systems |

This table highlights why service factor vs duty cycle must be considered together rather than separately.

Know more about Coincidence Factor vs Demand Factor

Impact on Motor Life Expectancy

Motor insulation life follows the Arrhenius rule. Every 10°C rise in temperature roughly halves insulation life. Continuous operation in service factor range combined with heavy duty cycling accelerates aging dramatically.

Consequences of poor service factor vs duty cycle planning include:

- Insulation breakdown

- Bearing grease degradation

- Rotor bar stress

- Frequent overload trips

A motor designed for 20 years of service may fail in five if operated continuously above rated load in a severe duty cycle.

Role of Ambient Temperature and Altitude

Service factor ratings assume standard ambient conditions, usually 40°C at sea level. High ambient temperature or altitude reduces cooling effectiveness. In these cases, service factor vs duty cycle evaluation must be derated.

Engineers should:

- Reduce allowable load at high ambient

- Consider Class F or H insulation

- Increase frame size instead of relying on service factor

Duty cycle may also need reassessment because cooling periods become less effective.

VFD Applications and Modern Systems

Variable frequency drives change the service factor vs duty cycle discussion. At low speeds, motor cooling is reduced. A motor running at 30 Hz under heavy load may overheat even below rated current.

Best practices with VFDs:

- Use inverter-duty motors

- Add forced ventilation if torque is high at low speed

- Monitor winding temperature

Here duty cycle includes speed variation, not just on/off time.

Know more about Coincidence Factor vs Diversity Factor: The Load Calculation Mistake Engineers Still Make

Engineering Selection Checklist

When choosing a motor, evaluate service factor vs duty cycle using a structured approach:

- Determine actual load profile over time

- Identify peak torque and duration

- Confirm duty classification (continuous, intermittent, cyclic)

- Avoid sizing motor to run continuously in service factor

- Verify NEC conductor and overload settings

- Check ambient and enclosure cooling

- Use thermal protection devices where duty is severe

This process ensures the motor is neither undersized nor excessively oversized.

Final Engineering Perspective

Service factor vs duty cycle is not a theoretical debate. It is a practical reliability issue that affects energy efficiency, maintenance cost, and system uptime. Service factor provides a short-term safety margin, while duty cycle defines the long-term thermal behavior of the motor.

Know more about Coincidence Factor vs Diversity Factor: The Load Calculation Mistake Engineers Still Make

Smart engineers treat service factor as a buffer, not a target. They design around the true duty cycle, use proper protection, and size motors based on realistic operating data. When service factor vs duty cycle is correctly understood, motors run cooler, last longer, and comply fully with NEC requirements.

In modern facilities where loads vary and energy efficiency matters, careful evaluation of service factor vs duty cycle is one of the most valuable steps in motor system design.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#ServiceFactorVsDutyCycle, #MotorSizing, #ElectricalStandards, #NECMotors, #IndustrialEquipment, #DutyCycleCalculation, #MotorServiceFactor, #ElectricalDesign, #EquipmentSizing, #EngineeringReference