Best Rotor Earth Fault Protection for Brushless Generator | Working, Types & Settings Explained

Rotor earth fault protection for brushless generator is one of the most important aspects of modern power generation systems. A fault in the rotor circuit can lead to reduced insulation life, loss of excitation, and even complete generator failure. While brushless excitation systems are designed for reliability, they are not immune to insulation degradation over time.

Table of Contents

In this article, we will explain what rotor earth fault protection is, how it works, different protection methods, and which system offers the best solution for brushless generators. This guide also supports the rotor earth fault protection calculator, helping you evaluate fault detection settings and insulation health accurately.

Understanding Rotor Earth Fault Protection for Brushless Generator

In a brushless generator, excitation is provided through a rotating exciter and rotating rectifier assembly. This setup removes the need for brushes and slip rings, improving reliability. However, the DC field winding on the rotor is still insulated from the rotor body. If the insulation between the field winding and the rotor core fails, an earth fault occurs.

Rotor earth fault protection detects this fault before it causes major damage. The protection system continuously monitors the insulation resistance between the rotor winding and earth. If it falls below a specific threshold, an alarm or trip is initiated.

This protection is critical because a single earth fault may seem harmless but can quickly develop into a second fault, resulting in a short circuit within the rotor winding. Such faults can cause severe thermal stress, mechanical vibration, and possible generator outage.

Use our online tool Generac Generator Size Calculator – Find the Right Generator Size

Why Rotor Earth Fault Protection Is Essential

Brushless generators operate under high mechanical and electrical stress. Over time, insulation in the rotor winding deteriorates due to heat, moisture, dirt, or aging. If the first earth fault occurs and remains undetected, the next fault can short the rotor winding, damaging the magnetic field and rendering the generator useless.

Proper rotor earth fault protection for brushless generator prevents these issues by continuously monitoring insulation health. It improves generator availability, reduces repair cost, and ensures system safety.

Common Causes of Rotor Earth Faults

- Moisture or contamination in the rotor core

- Aging of insulation materials

- Overheating due to overexcitation

- Mechanical stress from vibration

- Poor maintenance or oil leakage

These causes can be avoided with regular testing and continuous monitoring using a reliable protection system.

How Rotor Earth Fault Protection Works

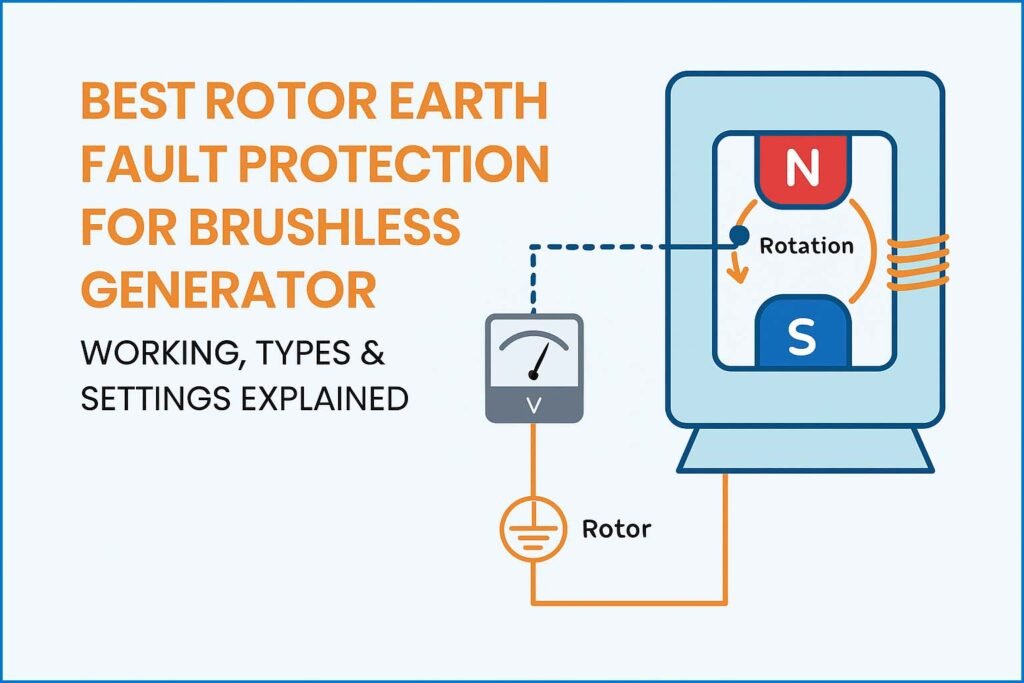

The working principle depends on injecting a voltage signal into the rotor circuit and detecting any leakage current that flows to the ground. In brushless generators, since the rotor circuit is isolated from stationary components, special techniques are used.

A simplified diagram of operation is as follows:

| Component | Function |

|---|---|

| DC Field Winding | Provides magnetic field for generator |

| Exciter and Rectifier | Supplies DC to the rotor |

| Rotor Body | Acts as earth reference |

| Detection Circuit | Injects signal and monitors leakage current |

The protection system compares the current or voltage response to determine if insulation resistance has fallen below the safe value. If a low resistance is detected, the relay operates and gives an alarm or trips the system.

Know more about Static Excitation Systems Manufactured in US

Types of Rotor Earth Fault Protection for Brushless Generator

Different protection techniques are used depending on the generator size, excitation method, and monitoring requirements. Let’s look at the most effective ones.

1. DC Injection Method

In this method, a small DC voltage is applied between the rotor winding and ground using a high resistance. The current flowing through the resistance is measured. If insulation degrades, leakage current increases, signaling an earth fault.

This method is simple and low cost but cannot detect faults during operation because the DC excitation voltage interferes with measurement. It is suitable for offline testing during maintenance.

2. AC Injection Method

A low-frequency AC voltage (typically 20–30 Hz) is injected between the rotor circuit and earth. The current or voltage feedback is monitored using filters and detection relays.

AC injection allows online monitoring even when the generator is running. It can detect gradual insulation deterioration and helps plan preventive maintenance.

| Method | Voltage Type | Operation | Suitable for Online Monitoring | Accuracy |

|---|---|---|---|---|

| DC Injection | Direct Current | Offline | No | Moderate |

| AC Injection | Alternating Current | Online | Yes | High |

3. Third Harmonic Voltage Detection

This technique relies on analyzing the third harmonic component of the voltage in the rotor circuit. When an earth fault occurs, the distribution of third harmonic voltage changes, which can be detected by a monitoring relay.

This method is non-intrusive and does not require injection signals, but its accuracy depends on generator load and excitation system design.

4. Pulsed DC Injection

A modern version of DC injection, this method applies short DC pulses instead of continuous voltage. The pulses are synchronized to avoid interference with normal excitation. It provides online monitoring and high sensitivity.

Know more about What is the Protection Scheme of an Alternator Against Inter Turn Fault?

5. Bridge-Type Protection Circuit

Bridge-type circuits are commonly used in large brushless generators. They use a bridge network to compare voltages between the rotor and ground. When insulation weakens, the imbalance triggers a relay.

This technique is highly accurate, offers continuous protection, and can distinguish between partial and full earth faults.

Best Rotor Earth Fault Protection Method for Brushless Generator

For brushless generators, the best protection system is AC injection or pulsed DC injection type. These methods can monitor insulation continuously during operation, providing early warning before failure.

They offer better accuracy and reliability compared to offline systems. AC injection systems are widely used in modern digital generator protection relays.

| Parameter | AC Injection | Pulsed DC Injection | Third Harmonic Method |

|---|---|---|---|

| Online Monitoring | Yes | Yes | Yes |

| Accuracy | High | Very High | Medium |

| Maintenance Requirement | Low | Low | Low |

| Interference with Excitation | Minimal | None | None |

| Cost | Moderate | High | Moderate |

| Recommended Use | Medium to Large Generators | Large and Critical Generators | Supplementary Method |

The best rotor earth fault protection for brushless generator should have:

- Continuous online monitoring

- Adjustable insulation resistance threshold

- Fast response time

- Compatibility with digital protection relays

- Fault recording capability

Using the Rotor Earth Fault Protection Calculator

To simplify configuration, we have developed an online rotor earth fault protection calculator. It helps you determine suitable detection voltage, resistance values, and alarm settings.

How to Use the Calculator

- Enter the generator field voltage and rated power.

- Input the target insulation resistance (usually 10–50 kΩ).

- The calculator provides recommended injection voltage and resistor values.

- It also gives alarm and trip settings for insulation deterioration.

The calculator is designed for field engineers, maintenance staff, and students to understand protection configuration easily.

Know more about Protection Schemes for Alternator: Complete Guide

Example Calculation

| Parameter | Value |

|---|---|

| Rated Field Voltage | 125 V DC |

| Minimum Insulation Resistance | 20 kΩ |

| Recommended Injection Voltage | 24 V AC |

| Alarm Threshold | 25 kΩ |

| Trip Threshold | 15 kΩ |

With these settings, the protection relay will alarm if the insulation drops below 25 kΩ and trip the generator if it falls to 15 kΩ.

Maintenance and Testing of Rotor Earth Fault Protection

Regular maintenance ensures the protection system works accurately. Here are essential checks to perform:

- Verify insulation resistance using a megohmmeter during shutdown.

- Check AC or pulsed DC injection circuit continuity.

- Inspect all wiring connections and grounding points.

- Confirm that relay operates within the specified threshold.

- Log insulation readings for trend analysis.

Routine testing helps detect early insulation degradation and reduces the risk of catastrophic failure.

Advantages of Proper Rotor Earth Fault Protection

- Prevents costly rotor damage

- Ensures continuous power generation

- Provides early warning of insulation wear

- Enables planned maintenance

- Improves safety and system reliability

Well-designed rotor earth fault protection extends generator life and maintains power system stability.

Conclusion

Rotor earth fault protection for brushless generator is a vital safeguard against insulation failure in the rotor winding. Among all methods, AC injection and pulsed DC injection techniques offer the best performance because they provide continuous online monitoring with high sensitivity. They are suitable for both small and large generators, ensuring dependable operation and early fault detection.

Know more about Types of Alternator Protection: Complete Guide with Technical Insights

Using our rotor earth fault protection calculator, you can easily configure accurate settings for your specific generator type. By integrating this system, you minimize downtime, protect valuable assets, and achieve long-term reliability in your power plant.

In short, proper rotor earth fault protection is not just a safety measure—it is an investment in efficiency and reliability for every brushless generator system.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#RotorEarthFaultProtection, #BrushlessGenerator, #GeneratorProtection, #ElectricalEngineering, #PowerGeneration, #GeneratorSafety, #FaultDetection, #ExcitationSystem, #EarthFaultRelay, #RotorProtection, #GeneratorMaintenance, #IndustrialAutomation, #ProtectionRelay, #ElectricalFaults, #EnergyEngineering

Thanks for sharing superb informations. Your website is so cool. I’m impressed by the details that you have on this web site. It reveals how nicely you perceive this subject. Bookmarked this web page, will come back for extra articles. You, my friend, ROCK! I found simply the info I already searched all over the place and just could not come across. What a great website.