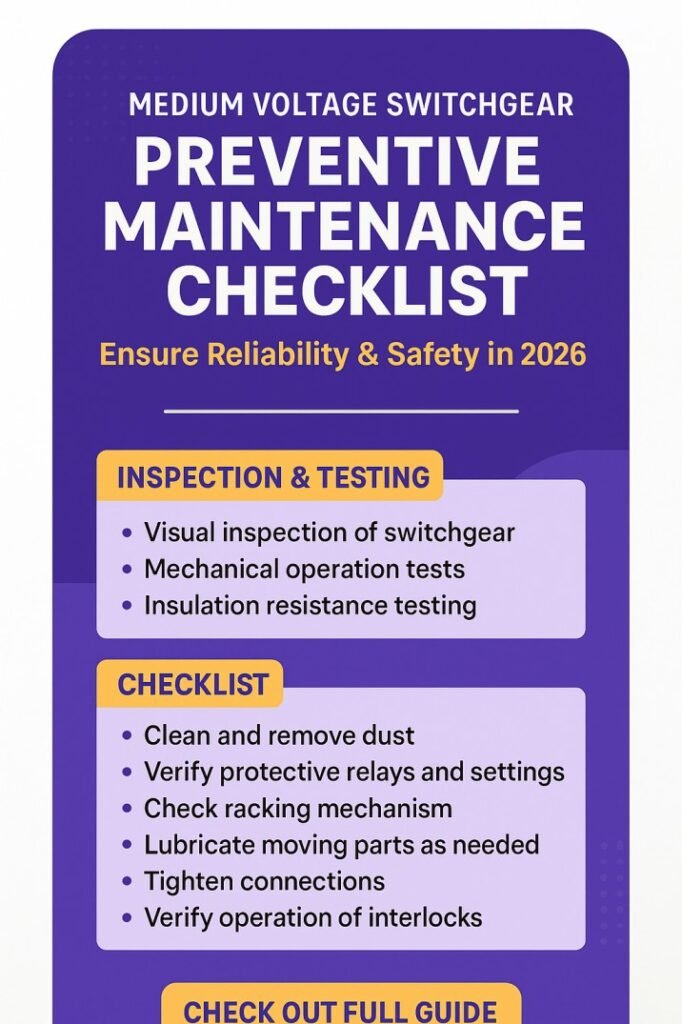

Medium Voltage Switchgear Preventive Maintenance Checklist: Ensure Reliability & Safety in 2026

Medium voltage switchgear is a critical component of electrical distribution systems, responsible for controlling, protecting, and isolating electrical equipment in commercial, industrial, and utility environments. Ensuring its optimal performance is essential for system reliability, safety, and longevity. Implementing a thorough medium voltage switchgear preventive maintenance checklist helps engineers, technicians, and facility managers identify potential issues before they escalate, reduce downtime, and maintain compliance with safety standards. In 2026, with increasing system complexity and higher safety demands, following a structured preventive maintenance program has become more important than ever.

Preventive maintenance of medium voltage switchgear involves routine inspections, cleaning, lubrication, testing, and component replacement. It aims to prevent failures caused by mechanical wear, electrical faults, environmental effects, or operator errors. The checklist provides a systematic approach, ensuring that no critical aspect is overlooked, and allows maintenance teams to maintain a high standard of operational safety. This article presents a comprehensive medium voltage switchgear preventive maintenance checklist, covering all essential areas, practical recommendations, and modern techniques to ensure reliability and safety.

Use our online tool for free Sub Panel Breaker Size Calculator – Find the Right Breaker for Your Electrical Sub Panel

Importance of Preventive Maintenance in Medium Voltage Switchgear

Medium voltage switchgear operates under demanding conditions, including fluctuating loads, high currents, and harsh environmental factors. Without proper maintenance, several issues can arise:

- Insulation degradation leading to short circuits

- Loose connections causing overheating

- Corrosion affecting contacts and panels

- Mechanical wear of circuit breakers and operating mechanisms

- Failures in protection relays or control systems

A well-structured medium voltage switchgear preventive maintenance checklist allows maintenance personnel to identify these issues proactively, preventing equipment failure, reducing repair costs, and extending service life. It also ensures compliance with international standards such as IEC 62271 and IEEE 1564, which emphasize the importance of periodic inspection and testing of switchgear equipment.

Know more about GIS vs AIS Switchgear: Best Key Differences Every Electrical Engineer Must Know

Key Components to Include in the Checklist

A comprehensive checklist should cover all critical components of medium voltage switchgear. The main areas include:

- Visual Inspection

Begin with a thorough visual examination of all switchgear compartments. Look for signs of overheating, corrosion, loose fittings, physical damage, or oil leakage in oil-insulated switchgear. Ensure that warning labels and safety signs are intact and readable. - Mechanical Checks

Inspect moving parts such as operating mechanisms, interlocks, and hinges. Verify proper lubrication of hinges, gear trains, and spring-operated mechanisms. Confirm smooth operation of circuit breakers and disconnectors without undue resistance or sticking. - Electrical Connections

Tighten all electrical connections to prevent arcing and overheating. Check busbars, terminals, and cable terminations for discoloration or burn marks. Ensure proper torque according to manufacturer specifications. - Insulation and Dielectric Tests

Perform insulation resistance measurements for busbars, cables, and transformers. For vacuum and SF6 circuit breakers, conduct contact resistance tests and dielectric withstand tests to ensure insulation integrity. - Protective Relays and Control Systems

Test and calibrate protective relays, control circuits, and signaling devices. Check settings, verify trip functions, and confirm that backup protection systems are functional. - Cleaning and Housekeeping

Remove dust, dirt, and moisture from switchgear panels, cubicles, and compartments. Ensure adequate ventilation and maintain a clean, dry environment to prevent contamination and condensation.

Use our online tool for free Sub Panel Wire Size Calculator – Accurate Wire Gauge & Load Sizing Tool

Sample Medium Voltage Switchgear Preventive Maintenance Checklist Table

The following table provides a practical example of a medium voltage switchgear preventive maintenance checklist for field use. It includes inspection items, frequency, and recommended actions.

| Inspection Area | Task Description | Frequency | Recommended Action |

|---|---|---|---|

| Visual Inspection | Check for physical damage, corrosion, and cleanliness | Monthly | Clean panels, tighten loose screws, repair damaged parts |

| Circuit Breakers | Operate manually to verify smooth movement | Quarterly | Lubricate mechanisms, adjust operating linkages |

| Electrical Connections | Tighten busbar and terminal connections | Quarterly | Use calibrated torque wrench, replace damaged connectors |

| Insulation Resistance | Measure insulation resistance of busbars and cables | Semi-Annually | Perform insulation tests, identify degraded insulation |

| Protective Relays | Test and calibrate relays, verify trip operations | Annually | Adjust settings, replace faulty relays if necessary |

| Control Panels | Inspect wiring, signaling devices, and interlocks | Quarterly | Correct loose wiring, replace defective indicators |

| SF6 Circuit Breakers | Check gas pressure, inspect for leaks | Semi-Annually | Refill or repair leaks, test breaker operation |

| Earthing System | Verify grounding connections and resistance | Annually | Tighten connections, repair corroded grounding points |

| Environmental Factors | Check ventilation, moisture, and dust levels | Monthly | Install dehumidifiers, clean filters, maintain airflow |

| Documentation | Update maintenance records, note observations | Every Inspection | Ensure traceability and compliance with standards |

This table allows maintenance teams to systematically follow the medium voltage switchgear preventive maintenance checklist, ensuring no critical task is overlooked.

Use our online tool for free Wire Size Calculator for Subpanels and Feeders – NEC Guidelines Included

Best Practices for Medium Voltage Switchgear Maintenance

Following best practices can enhance the effectiveness of preventive maintenance programs:

- Follow Manufacturer Guidelines: Each switchgear model may have specific requirements. Always refer to manufacturer manuals for torque specifications, lubrication types, and testing procedures.

- Schedule Regular Inspections: Use a combination of monthly, quarterly, and annual inspections to cover both minor and critical components.

- Use Proper Tools and Safety Equipment: High-voltage switchgear maintenance requires insulated tools, protective gloves, arc flash-rated clothing, and safety barriers.

- Record and Track Maintenance: Maintain detailed logs of inspections, tests, repairs, and replacements. This helps in trend analysis and predictive maintenance planning.

- Train Personnel: Ensure maintenance staff are trained in electrical safety, switchgear operation, and diagnostic techniques. Skilled personnel reduce the risk of human error and accidents.

Know more about Industrial Control Panel Design Software – Best Tools, Features & Pro Tips for Engineers

Common Maintenance Challenges and Solutions

Medium voltage switchgear maintenance comes with certain challenges. Understanding these can help in implementing an effective preventive program:

- Environmental Degradation: Dust, moisture, and chemicals can degrade switchgear. Regular cleaning, sealed enclosures, and dehumidifiers mitigate these effects.

- Mechanical Wear: Circuit breaker mechanisms and interlocks can wear out. Scheduled lubrication and operational tests help identify wear early.

- Electrical Faults: Loose connections or insulation breakdown can cause overheating and outages. Periodic torque checks and insulation testing prevent failures.

- Documentation Gaps: Incomplete maintenance records can lead to missed inspections. Digital record-keeping or CMMS (Computerized Maintenance Management Systems) ensures accountability and trend analysis.

Advantages of Using a Preventive Maintenance Checklist

Implementing a medium voltage switchgear preventive maintenance checklist offers multiple benefits:

- Enhances equipment reliability and reduces unplanned downtime

- Improves personnel safety by minimizing electrical hazards

- Extends the lifespan of switchgear and reduces replacement costs

- Facilitates compliance with industry standards and regulatory requirements

- Provides a structured approach for maintenance planning and scheduling

Find more about Low Voltage Switchgear vs Medium Voltage Switchgear: Important Differences Every Engineer Must Know

Future Trends in Medium Voltage Switchgear Maintenance

In 2026, medium voltage switchgear maintenance is evolving with technology. Predictive maintenance using IoT sensors, thermal imaging, and partial discharge monitoring is becoming increasingly popular. These technologies complement traditional preventive maintenance, providing early warning of potential failures. Integrating digital monitoring with the preventive maintenance checklist improves decision-making, resource allocation, and operational efficiency.

Conclusion

A medium voltage switchgear preventive maintenance checklist is an essential tool for ensuring the reliability, safety, and longevity of electrical distribution systems. By systematically inspecting, testing, and maintaining every critical component, maintenance teams can prevent costly failures, reduce downtime, and comply with industry standards.

Combining traditional preventive maintenance practices with modern monitoring technologies ensures that medium voltage switchgear operates safely and efficiently in 2026 and beyond. Following this checklist not only protects equipment but also safeguards personnel, making it a vital aspect of responsible electrical engineering management.

Find all about Top 15 Medium Voltage Switchgear Manufacturers in UAE: Ultimate Guide for Engineers & Buyers

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#MediumVoltageSwitchgear, #PreventiveMaintenance, #SwitchgearChecklist, #ElectricalMaintenance, #MVSwitchgear, #IndustrialSafety, #PowerSystemMaintenance, #ElectricalInspection, #MaintenanceTips, #SwitchgearSafety