IEC Standard for PLC Programming: Best Practical Compliance Guide Engineers Actually Use

In modern automation, reliable control depends on structured and well-documented programming practices. The iec standard for plc programming provides a globally accepted framework that ensures control systems remain consistent, maintainable, and safe across different manufacturers. Engineers, technicians, and integrators rely on these guidelines when designing, modifying, or troubleshooting programmable logic controllers in industrial environments.

Table of Contents

Instead of treating PLC development as vendor-specific logic creation, the iec standard for plc programming promotes a unified method based on defined programming languages, naming rules, documentation structure, and validation practices. This approach reduces downtime, improves system scalability, and simplifies cross-platform integration. Understanding how these requirements translate into daily engineering work is essential for professionals working in manufacturing, process industries, utilities, and infrastructure projects.

Know more about Remote Monitoring with PLC and IoT Integration

What the IEC Framework Covers for PLC Development

The foundation of the iec standard for plc programming comes from IEC 61131, which defines how control programs should be structured, executed, and documented. The standard is not limited to syntax. It also addresses memory organization, variable management, program execution models, and modular design principles.

IEC 61131 introduces a consistent architecture that separates configuration, resources, tasks, and program organization units. This structure helps engineers build scalable automation solutions that remain readable over time. When a plant expands or undergoes modernization, a standardized architecture ensures that future teams can understand existing logic without reverse engineering.

The framework also promotes lifecycle discipline. From initial design to commissioning and maintenance, engineers follow traceable documentation and version control. This ensures that every change is recorded, reviewed, and validated before deployment into production systems.

Standard Programming Languages Defined by IEC

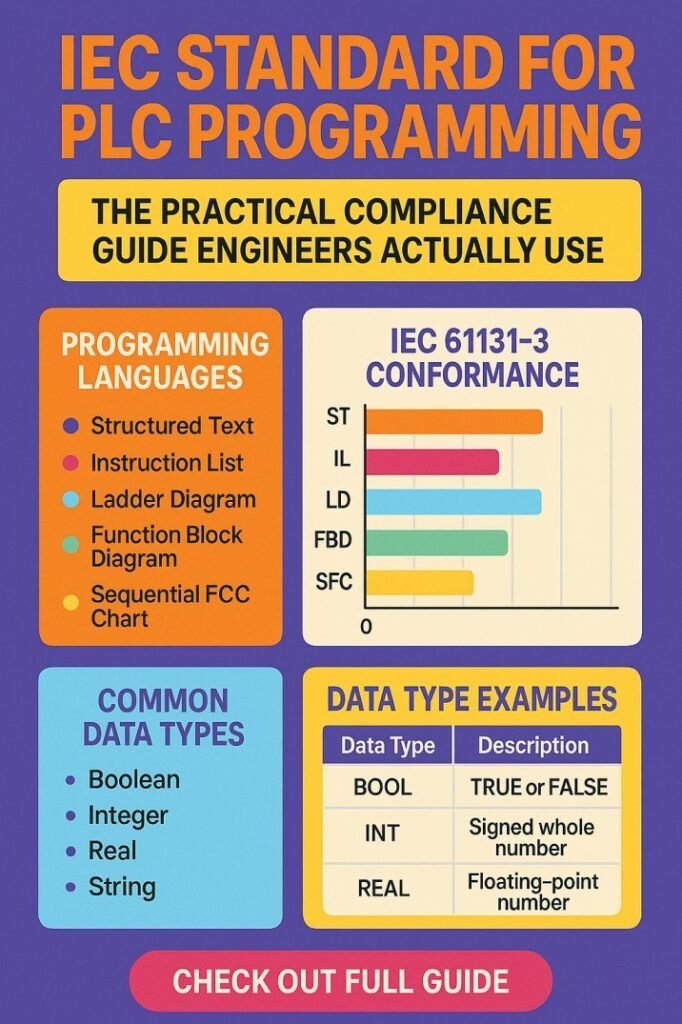

One of the most practical aspects of the iec standard for plc programming is the definition of five programming languages that can be used interchangeably depending on the application. Each language is suited for specific control strategies, improving efficiency and clarity.

Table: IEC Programming Languages and Typical Applications

| Language | Abbreviation | Best Use Case | Key Advantage |

|---|---|---|---|

| Ladder Diagram | LD | Discrete control, relay replacement | Easy troubleshooting for technicians |

| Function Block Diagram | FBD | Process control, analog logic | Visual representation of signal flow |

| Structured Text | ST | Complex calculations, algorithms | High flexibility and precision |

| Instruction List | IL | Legacy systems | Compact representation of logic |

| Sequential Function Chart | SFC | Batch processes, sequences | Clear visualization of process steps |

These standardized languages allow engineers from different backgrounds to collaborate effectively. A maintenance technician may prefer Ladder Diagram for fault tracing, while a control engineer might implement advanced calculations using Structured Text.

Know more about Top SCADA Software Platforms for Energy Sector

Program Organization and Modular Design

The iec standard for plc programming strongly emphasizes modular programming. Instead of writing long, monolithic routines, engineers divide logic into reusable program organization units such as functions, function blocks, and programs.

Functions handle single tasks with defined inputs and outputs. Function blocks allow internal memory and are ideal for devices such as motors, valves, and PID loops. Programs combine these elements to execute complete control strategies.

This modular structure improves troubleshooting. If a motor fails to start, the engineer can inspect the dedicated function block rather than searching through an entire project. It also enables faster commissioning because validated modules can be reused across multiple machines.

Know more about Industrial IoT Sensors in Automation: Cost and Integration

Table: Program Organization Units in IEC PLC Architecture

| Unit Type | Memory Capability | Typical Application |

|---|---|---|

| Function | No internal memory | Mathematical operations |

| Function Block | Retains state | Motor control, timers |

| Program | Full logic structure | Machine or process control |

Using standardized program units ensures that documentation remains aligned with logic execution. It also supports code reusability, which reduces engineering hours in large automation projects.

Naming Conventions and Data Handling Requirements

Another key area covered by the iec standard for plc programming is variable management and naming consistency. Clear tag naming improves readability and reduces the chance of wiring or configuration errors.

Typical conventions include prefixes that identify the data type or device category. For example, digital inputs, analog values, and internal flags follow structured naming patterns. This allows maintenance teams to quickly identify signal sources.

Know more about HMI vs SCADA: Which System Should You Choose?

Data typing is equally important. IEC defines strict data types such as BOOL, INT, REAL, and TIME. Using appropriate data types ensures predictable execution and prevents overflow or conversion errors during runtime.

Proper data organization also supports HMI integration. When tags follow a consistent format, operator interfaces can be developed quickly without extensive mapping or interpretation.

Execution Model and Task Management

The iec standard for plc programming also specifies how programs execute within the controller. Tasks define execution frequency and priority, ensuring deterministic behavior in time-critical applications.

Cyclic tasks run continuously at defined intervals, making them suitable for real-time control loops. Event-driven tasks execute when a trigger occurs, such as a sensor change or communication request.

Managing execution timing correctly prevents processor overload and ensures stable control. For example, high-speed safety interlocks may run in a fast cyclic task, while data logging operates at a slower rate.

Engineers who follow this structured execution model achieve predictable scan times, which is essential in applications involving motion control or high-speed manufacturing.

Know more about PLC Programming Salary 2026 – Experience-Wise Pay, Country Comparison & Skills That Boost Income

Documentation and Version Control Expectations

Comprehensive documentation is a practical requirement within the iec standard for plc programming. Every project should include clear descriptions of program structure, variable lists, I/O mapping, and revision history.

Documentation is not only for compliance. It directly affects maintenance efficiency. When a technician investigates a fault, accurate comments and signal descriptions reduce troubleshooting time.

Version control is also encouraged. Each modification should be recorded with date, author, and change description. This traceability ensures that unintended changes can be rolled back if required.

Standardized documentation also simplifies audits and system upgrades. When new engineers join a project, they can quickly understand logic flow without extensive handover sessions.

Testing, Validation, and Commissioning Practices

Testing procedures are a critical part of the iec standard for plc programming. Before deploying logic to live equipment, engineers perform simulation, offline testing, and functional verification.

Simulation tools allow engineers to validate sequences without energizing physical devices. This reduces commissioning risks and prevents equipment damage.

Know more about SCADA HMI Software Cost in 2026 – Pricing, Licenses & Best Value Options

During site commissioning, validation includes I/O checks, alarm verification, and sequence confirmation. Each function block is tested under normal and fault conditions.

Table: Typical PLC Validation Steps

| Stage | Objective | Outcome |

|---|---|---|

| Simulation Testing | Verify logic operation | Early error detection |

| Factory Acceptance Test | Confirm functional requirements | Customer approval |

| Site Commissioning | Validate field wiring | Reliable startup |

| Performance Monitoring | Ensure long-term stability | Reduced downtime |

Following structured validation procedures ensures that control systems operate safely from the first production cycle.

Cybersecurity and Network Integration Considerations

Modern automation systems are increasingly connected through industrial Ethernet, SCADA platforms, and remote diagnostics. The iec standard for plc programming aligns with secure design principles that protect control logic from unauthorized access.

Know more about PLC vs DCS: Main Differences for Industrial Automation

Access control, password management, and user role definitions help prevent accidental or malicious changes. Secure communication protocols ensure data integrity between PLCs and supervisory systems.

Network segmentation is another recommended practice. Separating control networks from corporate IT reduces exposure to external threats. Engineers implementing standardized security measures maintain both operational continuity and regulatory compliance.

Practical Benefits for Maintenance and Lifecycle Management

The long-term value of the iec standard for plc programming becomes clear during maintenance and upgrades. Plants that follow structured programming experience faster fault resolution and lower lifecycle costs.

Standardized code allows spare PLCs or upgraded controllers to be integrated without rewriting entire projects. Training requirements are also reduced because engineers encounter familiar program structures across different installations.

Consistency across multiple production lines enables centralized monitoring and analytics. Data collected from standardized tags can be compared across facilities, supporting predictive maintenance strategies.

Ultimately, adherence to the standard improves reliability while reducing engineering risk. It transforms PLC logic from isolated code into a documented, scalable asset that supports operational excellence.

Common Implementation Challenges and How Engineers Address Them

Despite its advantages, adopting the iec standard for plc programming can present challenges. Legacy systems may use vendor-specific conventions that do not align with modern practices. Migration requires careful planning to avoid production disruption.

Explore everything about Automation Engineer Certification Cost in 2026 – Fees, Duration & Best Value Programs

Another challenge is maintaining discipline during fast-paced projects. Engineers sometimes bypass naming rules or documentation to save time. However, experienced teams establish templates and libraries that enforce compliance automatically.

Training also plays a major role. Organizations that invest in structured PLC programming education see faster adoption and fewer configuration errors. Over time, standardized workflows become part of normal engineering culture.

Conclusion

The iec standard for plc programming provides a proven framework that improves consistency, safety, and maintainability in industrial automation. By defining programming languages, modular architecture, execution models, documentation practices, and validation procedures, it ensures that PLC systems remain reliable throughout their lifecycle.

Find all about SCADA vs DCS Comparison: Best Professional Guide for Engineers

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard, #PLCProgramming, #IndustrialAutomation, #IEC61131, #ControlSystems, #AutomationEngineering, #PLCBasics, #ElectricalEngineering, #AutomationStandards, #IndustrialControl