How to Wire a Motor Starter with Overloads – Step-by-Step Wiring Guide for Safe Motor Control

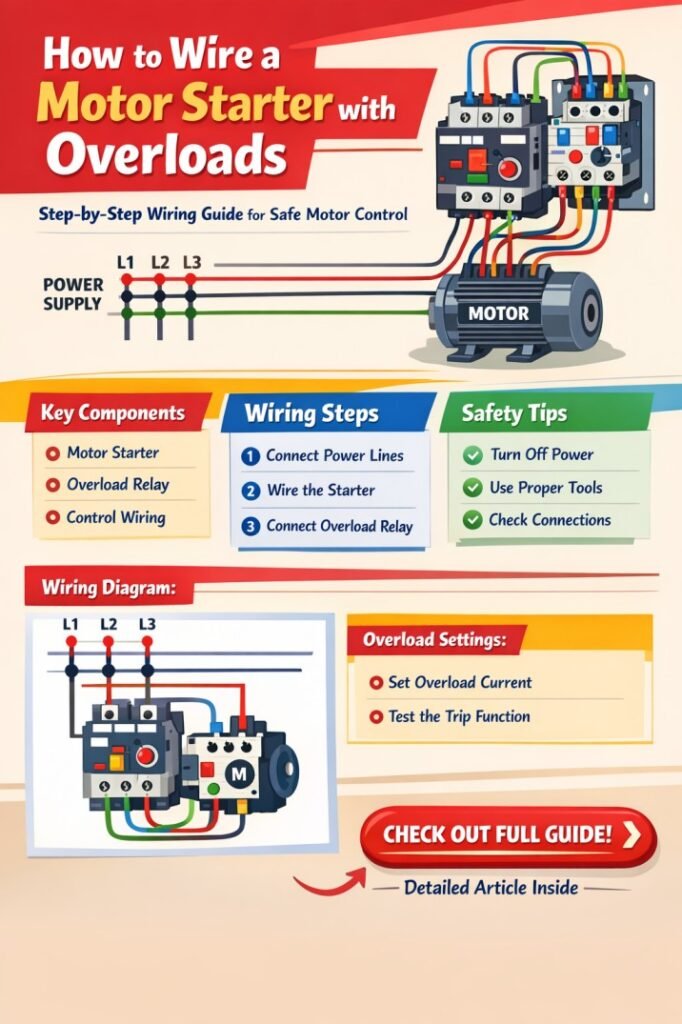

Learning how to wire a motor starter with overloads is a core skill for electricians, maintenance engineers, and industrial technicians. A properly wired motor starter protects the motor from overcurrent, overheating, and electrical faults while ensuring smooth and reliable operation. Incorrect wiring, on the other hand, can cause frequent trips, motor damage, or even serious safety hazards.

This detailed guide explains how to wire a motor starter with overloads in a clear, practical, and safe manner. The focus is on real-world wiring practices used in industrial and commercial installations, with attention to readability and long-term reliability.

Table of Contents

Understanding a Motor Starter and Overloads

Before you wire a motor starter with overloads, it is important to understand what each component does and why it matters in a motor control circuit.

A motor starter is a combination of a contactor and an overload relay. The contactor controls the switching of power to the motor, while the overload relay protects the motor from excessive current over a period of time.

Key functions of a motor starter include:

- Safe starting and stopping of the motor

- Protection against overload conditions

- Isolation of control and power circuits

- Improved motor lifespan

The overload relay does not trip instantly like a circuit breaker. Instead, it responds to sustained overcurrent that can overheat motor windings.

Know more about Difference Between Star Delta and DOL Starter: A Comprehensive Guide

Components Required to Wire a Motor Starter with Overloads

The table below lists the essential components commonly used in a standard direct-on-line motor starter circuit.

| Component | Purpose |

|---|---|

| Contactor | Switches motor power ON and OFF |

| Overload Relay | Protects motor from overload current |

| Start Push Button (NO) | Energizes the control circuit |

| Stop Push Button (NC) | De-energizes the control circuit |

| Control Fuse or MCB | Protects the control wiring |

| Three-Phase Motor | Electrical load |

| Control Transformer (if needed) | Steps down control voltage |

Having the correct components ensures that when you wire a motor starter with overloads, the circuit remains safe and compliant with electrical standards.

Safety Precautions Before Wiring

Safety should always come first. Even experienced professionals follow strict precautions before starting work.

- Isolate the power supply and lock it out

- Verify zero voltage using a tester

- Use properly rated cables and terminals

- Follow local electrical codes and standards

- Wear insulated gloves and safety glasses

These steps reduce the risk of electric shock and equipment damage when you wire a motor starter with overloads.

Know more about Motor Overload Protection Chart: Important Concepts

Power Circuit Wiring Explained

The power circuit carries the main current to the motor. It must be wired correctly to handle the motor’s full load current.

Steps for wiring the power circuit:

- Connect the three-phase supply to the contactor line terminals (L1, L2, L3)

- Connect the contactor load terminals (T1, T2, T3) to the overload relay input

- Connect the overload relay output terminals to the motor terminals

- Ensure proper earthing of the motor body

The overload relay must always be placed between the contactor and the motor. This positioning allows it to sense the actual motor current.

Control Circuit Wiring Step by Step

The control circuit operates at a lower current and controls the contactor coil. This is where many wiring mistakes happen, so attention to detail is important.

Follow these steps to wire a motor starter with overloads in the control circuit:

- Connect the control supply phase to the stop push button (NC)

- From the stop button, connect to the start push button (NO)

- From the start button, connect to the contactor coil terminal A1

- Connect the auxiliary holding contact of the contactor parallel to the start button

- Route the circuit through the overload relay NC contact

- Connect coil terminal A2 to the control neutral or return phase

This arrangement ensures that if an overload occurs, the overload contact opens and de-energizes the contactor coil.

Know more about Thermal Overload Relay: Working Principle, Types and Important Settings Calculation

Typical Control Circuit Logic

Understanding the logic helps troubleshoot issues later.

| Condition | Contactor State | Motor Status |

|---|---|---|

| Start button pressed | Energized | Running |

| Start button released | Held by auxiliary contact | Running |

| Stop button pressed | De-energized | Stopped |

| Overload trip | De-energized | Stopped |

This logic is standard in most industrial motor control panels.

Setting the Overload Relay Correctly

Proper overload setting is just as important as correct wiring. Incorrect settings can lead to nuisance tripping or motor damage.

General guidelines:

- Set overload current to motor full load current from nameplate

- Use thermal class recommended by the motor manufacturer

- Reset mode should be manual for critical applications

- Test overload trip function after wiring

When you wire a motor starter with overloads, always verify the settings before energizing the motor.

Know more about How does the star delta starter reduce starting current? Important Concepts

Common Wiring Mistakes to Avoid

Many failures occur due to simple but avoidable mistakes.

- Skipping the overload NC contact in control wiring

- Loose terminal connections

- Incorrect control voltage applied to coil

- Overload relay set too low or too high

- Mixing control and power wiring routes

Avoiding these errors improves system reliability and safety.

Testing and Commissioning the Motor Starter

After you wire a motor starter with overloads, proper testing ensures the system works as intended.

Recommended testing steps:

- Check continuity of control circuit

- Verify correct phase sequence

- Test start and stop operation without load

- Simulate overload trip to confirm shutdown

- Monitor motor current during first run

Testing reduces downtime and protects both equipment and personnel.

Know more about Motor Starter Types: A Powerful Guide with 7 Key Options You’ll Appreciate

Applications of Motor Starters with Overloads

Motor starters with overload protection are used in many industries.

Common applications include:

- Pumps and compressors

- Conveyor systems

- HVAC motors

- Machine tools

- Industrial fans and blowers

In all these applications, knowing how to wire a motor starter with overloads is a valuable and practical skill.

Maintenance Tips for Long-Term Reliability

Routine inspection keeps motor starters functioning properly.

- Tighten terminals periodically

- Inspect contactor contacts for wear

- Check overload relay calibration annually

- Clean dust and debris from panels

- Record trip events for analysis

Regular maintenance ensures that the system continues to perform safely.

Know more about Motor Starter Size Chart: 7 Essential Insights for Better Selection

Final Thoughts

Understanding how to wire a motor starter with overloads is essential for safe motor control in any electrical installation. By following correct wiring practices, setting the overload accurately, and testing the system thoroughly, you can protect motors from damage and ensure reliable operation.

Whether you are installing a new motor or troubleshooting an existing panel, applying the principles explained in this guide will help you wire a motor starter with overloads confidently and professionally. Know more about VFD vs Soft Starter: Key Differences You Must Know for Motor Control

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#HowToWireAMotorStarter,#MotorStarterWiring,#OverloadRelayWiring,#ElectricalControlWiring,#IndustrialElectrical,#MotorProtection,#ElectricalEngineering,#ControlPanelWiring,#ThreePhaseMotor,#ElectricalTips