High Voltage Gloves Testing Requirements: Essential Standards for Maximum Safety

High voltage gloves are a critical piece of personal protective equipment (PPE) for electricians, linemen, and technicians working with electrical systems. Ensuring these gloves meet strict testing standards is essential for preventing electrical accidents and maintaining workplace safety. Understanding high voltage gloves testing requirements helps professionals choose the right gloves and ensures compliance with safety regulations. This article provides a comprehensive guide to the essential standards, testing procedures, and maintenance practices for high voltage gloves.

Table of Contents

Importance of High Voltage Gloves

High voltage gloves serve as the first line of defense against electric shocks when working with live electrical equipment. The material, thickness, and manufacturing process of these gloves determine their insulation properties. Without proper testing, even high-quality gloves may fail under extreme voltage, putting workers at serious risk. Adhering to high voltage gloves testing requirements ensures gloves can withstand the electrical stress of everyday use.

Standards Governing High Voltage Gloves

Several international and national standards define the testing and classification of high voltage gloves. Compliance with these standards ensures gloves are safe for specific voltage levels. The most widely recognized standards include:

Find all about VLF Tan Delta Testing of MV Cables: Ensure Reliable High-Voltage Cable Performance

- ASTM D120: Defines the minimum requirements for insulating gloves used in electrical work in the United States.

- IEC 60903: International standard for electrical insulating gloves, covering design, testing, and performance.

- EN 60903: European equivalent of the IEC standard, ensuring gloves meet safety requirements in Europe.

These standards classify gloves according to their voltage rating, material, and testing procedures. Meeting these standards is mandatory for professional electricians and industrial workers.

Classification and Voltage Ratings

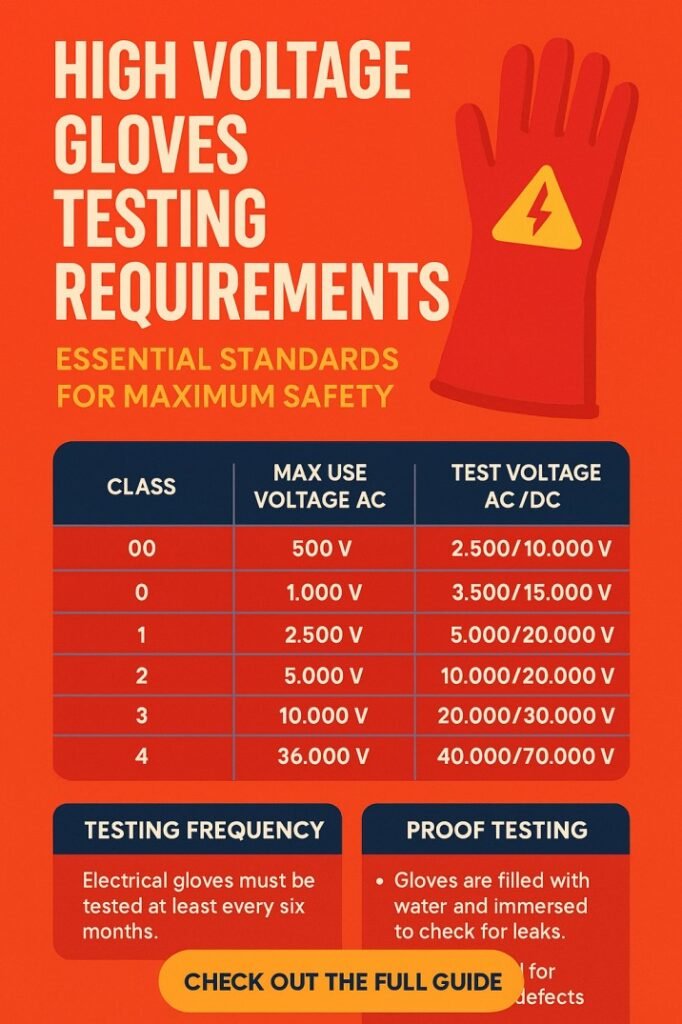

High voltage gloves are classified based on the maximum voltage they can safely handle. The following table summarizes the common classes:

| Class | Maximum Use Voltage (AC) | Maximum Use Voltage (DC) | Typical Applications |

|---|---|---|---|

| 00 | 500 V | 750 V | Low-voltage maintenance, residential wiring |

| 0 | 1,000 V | 1,500 V | Commercial electrical work, control panels |

| 1 | 7,500 V | 11,250 V | Industrial electrical maintenance, motors |

| 2 | 17,000 V | 25,500 V | Utility work, distribution lines |

| 3 | 26,500 V | 39,750 V | High-voltage industrial systems |

| 4 | 36,000 V | 54,000 V | Transmission lines, high-voltage labs |

Understanding these classifications is crucial for selecting gloves that match the voltage levels in your work environment. Using gloves rated lower than required increases the risk of electric shock and serious injury.

Explore all about Top 15 High Voltage Testing Services Indiana – Trusted Experts for Reliable Power Systems

Testing Procedures for High Voltage Gloves

High voltage gloves undergo rigorous testing to verify their insulating properties and durability. The main testing procedures include:

1. Dielectric Testing

Dielectric testing evaluates the glove’s ability to withstand high voltage without breakdown. Gloves are submerged in water or tested in air while a high-voltage source is applied. The procedure checks for leaks or punctures that could compromise safety. This test is mandatory under both ASTM D120 and IEC 60903 standards.

2. Air and Water Tests

Two common methods for detecting defects in gloves are:

- Air Test: The glove is inflated with air and submerged in water. Any bubbles indicate pinholes or weak areas.

- Water Leak Test: Water is used as a medium to detect leakage while the glove is under voltage stress.

These tests ensure the gloves are free from manufacturing defects that could lead to electrical accidents.

3. Physical and Visual Inspection

Before electrical testing, gloves are visually inspected for cuts, cracks, or signs of wear. Physical inspections also include checking for flexibility, thickness, and proper cuff length. Regular inspections are critical because even minor damage can compromise insulation.

Find all about Partial Discharge vs Tan Delta Cable Testing: Important Key Differences Every Engineer Must Know

4. Routine Field Testing

Even after passing standard tests, gloves require periodic field testing. Workers must test gloves daily before use using an air test or similar procedure to detect unnoticed damage. Routine field testing maintains consistent safety and extends the service life of gloves.

Material Considerations

High voltage gloves are typically made of natural rubber, synthetic rubber, or a combination. Each material has specific properties:

- Natural Rubber: Excellent elasticity and insulation, but can degrade in extreme temperatures or when exposed to chemicals.

- Synthetic Rubber (Neoprene, Nitrile): Offers higher resistance to ozone, UV light, and chemicals while maintaining insulating properties.

Material choice affects both comfort and durability, and it is important to follow high voltage gloves testing requirements that consider the specific material used.

Storage and Maintenance

Proper storage and maintenance prolong glove life and maintain electrical safety. Gloves should be stored in a cool, dry place away from direct sunlight and ozone sources. Avoid folding or creasing gloves, as this can weaken insulation. Using leather protectors over gloves reduces wear and prevents mechanical damage. Regular cleaning with mild soap and water removes dirt and chemicals that could degrade the rubber.

Explore details on High Voltage Cable Testing Procedure: Step-by-Step Guide for Safe & Accurate HV Cable Testing

Frequency of Testing

Testing frequency is determined by regulatory standards and glove usage. ASTM D120 recommends:

- Before each use: Visual inspection and air test.

- Every 6 months: Dielectric testing for gloves in regular use.

- Annually: Comprehensive inspection and electrical testing for gloves in frequent or harsh use.

Maintaining a testing log ensures compliance and allows tracking of glove performance over time.

Common Mistakes in Glove Testing

Even trained professionals sometimes make mistakes that compromise glove safety. Common errors include:

- Using gloves beyond their rated voltage class.

- Skipping pre-use inspections or air tests.

- Exposing gloves to chemicals or UV light without proper protection.

- Storing gloves improperly, leading to cracking or loss of elasticity.

Following high voltage gloves testing requirements and training workers on proper usage reduces these risks significantly.

Explore all about vlf testing procedure

Enhancing Safety Through Education

Education and training are key components of workplace electrical safety. Workers should be trained to:

- Recognize different glove classes and voltage ratings.

- Conduct proper pre-use and routine testing.

- Store, maintain, and replace gloves as needed.

- Understand the limitations of insulating gloves and use additional PPE if necessary.

Employers who invest in regular safety training reduce accidents and ensure compliance with industry standards.

Conclusion

Understanding high voltage gloves testing requirements is essential for anyone working in electrical environments. Compliance with ASTM D120, IEC 60903, and EN 60903 standards ensures that gloves can withstand electrical stress and protect workers from harm. Regular dielectric testing, visual inspection, proper storage, and employee training all contribute to maximum safety.

Find all about High Voltage Cable Testing Standards: Complete Guide for Engineers

Choosing the right gloves, adhering to testing schedules, and educating staff can significantly reduce electrical accidents and improve workplace safety. High voltage gloves are not just a protective tool—they are a vital component of electrical safety culture.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#HighVoltageGloves, #ElectricalSafety, #GloveTesting, #InsulatedGloves, #SafetyStandards, #HVGloves, #ElectricalProtection, #WorkerSafety, #VoltageTesting, #SafetyCompliance