Earth Cable Size Australia Calculator

Understanding earth cable size Australia is essential for ensuring electrical safety in residential, commercial, and industrial installations. The proper sizing of earth cables protects both people and equipment from electrical faults. It helps provide a clear path for fault current to flow safely into the ground. This article breaks down the technical details behind earth cable sizing in Australia, in a simple, easy-to-read format.

In Australia, earthing systems must follow the standards laid out in AS/NZS 3000, commonly known as the Australian Wiring Rules. These rules define the minimum requirements for safety in electrical installations. Proper earthing is critical not only for fault protection but also for voltage stability and equipment integrity.

Importance of Earth Cable Size Australia

Choosing the correct earth cable size Australia depends on several factors. These include system voltage, prospective fault current, cable length, and the material of the conductor. Copper and aluminium are the most common materials used. Copper is more conductive, so smaller cross-sectional areas are needed compared to aluminium.

If an earth cable is undersized, it may not handle the fault current. This could cause the cable to overheat, melt, or even start a fire. On the other hand, oversizing increases material cost unnecessarily. This is why accurate calculation is important.

Factors Affecting Earth Cable Size Australia

To determine the earth cable size Australia, professionals consider several parameters:

- Maximum fault current

- Duration of fault (until protection disconnects)

- Type of earthing system (TN, TT, IT)

- Cable installation method

- Cable material (copper or aluminium)

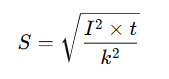

The equation used to calculate the minimum size is based on the adiabatic equation:

Where:

- S = minimum cross-sectional area in mm²

- I = fault current in amperes

- t = fault duration in seconds

- k = material constant (e.g. 143 for copper, 94 for aluminium)

This formula helps ensure the cable can carry the fault current without excessive temperature rise. Use our free Earth Cable Size Calculator below to calculate the earth cable size.

Earth Cable Size Table (Copper, Based on AS/NZS 3008)

Below is a general table showing typical earth cable size Australia recommendations for copper conductors in common scenarios. This table assumes fault duration of 0.4 seconds.

| Fault Current (A) | Minimum Earth Cable Size (mm²) |

|---|---|

| 1,000 | 10 |

| 2,000 | 16 |

| 5,000 | 35 |

| 10,000 | 70 |

| 15,000 | 95 |

| 20,000 | 120 |

| 25,000 | 150 |

These values are only indicative. Always use a proper Earth Cable Size Calculator or consult a licensed electrician to comply with AS/NZS 3000.

Copper vs Aluminium in Earth Cable Size Australia

In Australian installations, copper is more commonly used for earthing. However, aluminium is still permitted, especially in larger systems where weight and cost are factors. Since aluminium has higher resistance, larger cable sizes are needed compared to copper.

Here’s a simple comparison:

| Cable Material | Conductivity (% IACS) | Relative Size Needed |

|---|---|---|

| Copper | 100% | Base Reference |

| Aluminium | ~61% | ~1.6 times larger |

When aluminium is used, the Earthing Cable Size as Per IEC or AS/NZS must be strictly followed to avoid undersizing.

Earth Cable Size for Residential Installations

For domestic settings in Australia, most circuits use 2.5 mm² or 4 mm² copper for earthing. The main earth cable, connecting to the earth electrode or grid, is usually 6 mm² or larger, depending on the installation’s total fault current potential.

For example:

- Light circuits (10A or 16A): 1.5 mm² – 2.5 mm² CPC (Circuit Protective Conductor)

- Power circuits (20A – 32A): 2.5 mm² – 4 mm² CPC

- Main earth cable: 6 mm² – 16 mm² depending on main supply size

The exact size should be calculated, not guessed. Tools like an Earth Cable Size Calculator are helpful for this.

Earth Cable Size Australia in Commercial Installations

In commercial projects, the complexity increases. Higher fault currents and longer cable runs require more precise sizing. Often, earthing and bonding are part of a comprehensive bonding and grounding strategy. Earth bars, equipotential bonding, and multiple earth electrodes may be used.

An example from a commercial site:

- Transformer capacity: 500 kVA

- Fault current: 10 kA

- Fault duration: 1 second

- Required earth cable size (Copper): ~70 mm²

In such cases, engineers often follow the instrument earthing IEC standard and AS/NZS guidelines to coordinate between protective devices and earth conductors.

Voltage Drop and Earth Cable Size

Although voltage drop is more often a concern for active conductors, it’s still relevant in earthing. A high-resistance earth path might delay the operation of protective devices. That’s why keeping earth conductor lengths short and sizes appropriate is crucial.

For long cable runs in rural areas, even the Earthing Cable Size as Per IEC might need to be increased to maintain low earth loop impedance.

Installation Practices in Australia

When installing earth cables, the method affects performance. For example:

- Buried directly in soil: must be insulated and UV-resistant

- Inside conduit: easier to upgrade later

- Exposed to air: must be mechanically protected

Proper labeling, separation from active conductors, and earthing connections must comply with AS/NZS 3000. Grounding terminals, earthing pits, and bonding points should all be accessible and documented.

Earthing for Lightning and Surge Protection

In high-risk areas, such as telecom sites or tall buildings, additional measures are taken. Surge protectors, grounding rods, and mesh grounding systems are used. These installations often require much larger cable sizes — up to 120 mm² or more.

These setups usually align with both Australian regulations and instrument earthing IEC standard for sensitive electronics and signal lines.

Grounding Resistance Considerations

Earth cable size affects grounding resistance. To achieve low resistance (under 1 ohm is ideal for sensitive equipment), larger conductors, parallel runs, or enhanced electrodes are used.

If a single earth rod doesn’t suffice, more rods or chemical electrodes might be needed. The size and quality of the earth conductor play a direct role in maintaining this low resistance.

Final Thoughts on Earth Cable Size Australia

Properly sizing the earth cable size Australia is essential for any electrical installation. It ensures safety, equipment protection, and compliance with legal standards. Whether you’re wiring a small house or a large commercial facility, the key is to follow standards and perform accurate calculations.

Use an Earth Cable Size Calculator to start. Follow guidelines from AS/NZS 3000 and refer to IEC when needed. In sensitive installations, always check instrument earthing IEC standard to avoid errors.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#EarthCableSize, #AustraliaWiring, #ElectricalStandardsAU, #CableSizingGuide, #AS3000Compliance, #GroundingCable, #ElectricalSafety, #EarthingSystems, #CableInstallationAU, #WireGaugeAustralia, #ElectricalDesignAU, #ElectriciansAustralia, #CableSelection, #EarthingCableSize, #VoltageDropAustralia