Difference Between VLF and Megger: Best Guide and Applications

When it comes to testing the insulation of electrical cables and equipment, two commonly used methods are VLF testing and Megger testing. Both serve the same purpose; to check the insulation health; but they work in very different ways. Understanding the difference between VLF and Megger helps electrical engineers, maintenance teams, and technicians choose the right testing method for specific applications. This article explains their purpose, principle, test voltage levels, advantages, and limitations in detail.

Table of Contents

What Is VLF Testing?

VLF stands for Very Low Frequency testing. It is a high-voltage AC test method used primarily for medium- and high-voltage power cables. The test applies a sinusoidal or square-wave voltage at a frequency much lower than the normal 50 or 60 Hz power frequency; typically between 0.01 Hz and 0.1 Hz.

The main idea behind VLF testing is to stress the insulation of cables in a controlled manner, simulating real operating conditions without causing damage. Since the frequency is low, the capacitive current of the cable is small, allowing the test set to produce high voltage with low power demand.

VLF testing is commonly used for:

- Power cables rated from 6 kV up to 132 kV

- Cross-linked polyethylene (XLPE) and ethylene propylene rubber (EPR) insulated cables

- Acceptance tests after cable installation

- Diagnostic testing to evaluate insulation aging or partial discharge

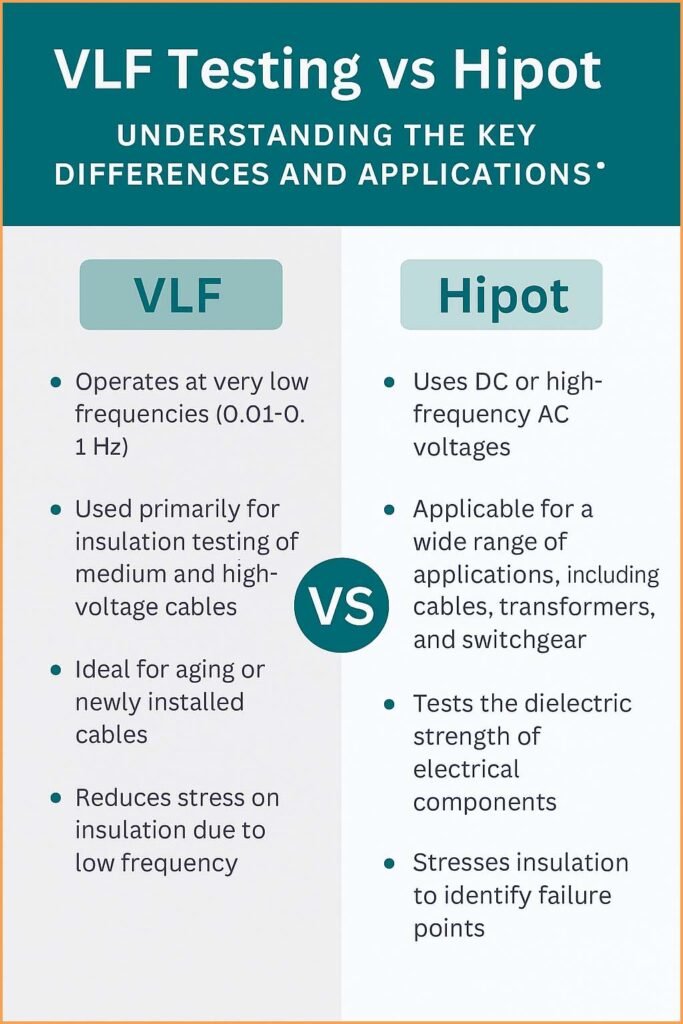

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

This method is widely preferred in field testing because it provides accurate insulation assessment without over-stressing the dielectric material.

What Is Megger Testing?

Megger testing, on the other hand, is a DC insulation resistance test. The name “Megger” actually comes from the popular brand of insulation resistance testers but is commonly used to describe the test itself.

A Megger applies a high DC voltage; typically 500V, 1000V, 2500V, or even 5000V. To measure the insulation resistance between conductors and earth or between conductors themselves. The resistance is measured in megaohms (MΩ), indicating how effectively the insulation resists electrical current leakage.

Know more about Best Megger Testers for Industrial Use (2025)

Megger testing is primarily used for:

- Low and medium-voltage cables

- Motors and generators

- Transformers

- Switchgear and circuit breakers

- Electrical installations during commissioning or maintenance

It is a quick and simple method to identify moisture ingress, insulation deterioration, or contamination in electrical systems.

The Main Difference Between VLF and Megger

The difference between VLF and Megger lies in the type of voltage applied, the frequency of operation, and the depth of diagnostic information they provide. While both test insulation integrity, they are suited for different voltage levels and purposes.

Table: Key Difference Between VLF and Megger

| Parameter | VLF Testing | Megger Testing |

|---|---|---|

| Full Form | Very Low Frequency Test | Insulation Resistance Test (Megger) |

| Type of Voltage | AC (Alternating Current) | DC (Direct Current) |

| Frequency Range | 0.01 Hz to 0.1 Hz | 0 Hz (Pure DC) |

| Measurement | Insulation withstand capability | Insulation resistance in megaohms |

| Equipment Tested | Medium to high-voltage cables | Low to medium-voltage cables, motors, transformers |

| Test Duration | 15 minutes to 1 hour | Few seconds to a few minutes |

| Output | Pass/Fail, leakage current, tan delta | Resistance value (MΩ) |

| Risk of Damage | Low (AC simulates real operation) | Higher for XLPE cables (DC stress can cause damage) |

| Application Type | Diagnostic and withstand test | Preventive maintenance and quick insulation check |

As seen in the table above, VLF testing provides a more realistic assessment of cable insulation health because it uses alternating voltage similar to operating conditions. Megger testing is more of a go/no-go test, giving a simple resistance value that indicates whether the insulation is good or degraded.

Know more about High Voltage Cable Testing Standards: Complete Guide for Engineers

Why VLF Testing Is Preferred for High Voltage Cables

In modern cable testing practices, VLF testing has largely replaced DC Megger tests for medium and high-voltage XLPE cables. The main reason is the effect of DC voltage on polymer insulation. When DC voltage is applied to polymer-based insulation, trapped charges can remain in the dielectric material, potentially causing premature failure during normal AC operation.

VLF testing eliminates this risk because it uses an alternating voltage at low frequency. It subjects the insulation to alternating stress, similar to real-life conditions, while limiting the overall energy stress on the dielectric.

Moreover, VLF testing allows advanced diagnostic techniques such as:

- Tan delta testing (to measure dielectric losses)

- Partial discharge testing (to detect localized insulation defects)

These diagnostics provide early warning of insulation aging and allow maintenance teams to plan replacements before catastrophic failure occurs.

When to Use Megger Testing

Megger testing remains an essential tool in electrical maintenance. It is quick, portable, and effective for lower-voltage systems and routine checks. For example, maintenance technicians use Megger tests to ensure the insulation of motors, transformers, and switchgear remains within acceptable limits.

The Megger test helps detect issues like:

- Moisture ingress

- Surface contamination

- Insulation deterioration due to aging

- Poor termination or connection insulation

Since the test is non-destructive, it can be performed frequently as part of preventive maintenance programs.

Advantages and Limitations of Each

Although both tests serve the same goal, they have unique advantages and limitations.

Advantages of VLF Testing

- Simulates real AC stress conditions

- Safe for modern XLPE and EPR cables

- Suitable for long cable runs with high capacitance

- Enables advanced diagnostics like tan delta and PD testing

Advantages of Megger Testing

- Simple, fast, and easy to perform

- Portable and low-cost equipment

- Ideal for low-voltage systems and periodic checks

- Immediate insulation resistance readings

Limitations

VLF testing requires heavier equipment and more setup time. It may not be ideal for small-scale maintenance jobs. Megger testing, while convenient, provides limited diagnostic detail and may over-stress polymeric insulation if used improperly on high-voltage cables.

Know more about IEC Standard for VRLA Battery – Complete Guide to Design, Testing, and Performance

Choosing Between VLF and Megger

Choosing the right test depends on the voltage level, insulation type, and purpose of testing. If the goal is to evaluate the long-term reliability of medium or high-voltage cables, VLF testing is the preferred method. If you just need a quick insulation resistance check on low-voltage systems or electrical equipment, Megger testing is sufficient.

Table: When to Choose Each Test

| Application Type | Recommended Test |

|---|---|

| High-voltage XLPE or EPR cables | VLF Test |

| Low-voltage power cables | Megger Test |

| Transformer insulation | Megger Test |

| Cable commissioning test | VLF Test |

| Routine maintenance check | Megger Test |

| Diagnostic or tan delta measurement | VLF Test |

Conclusion

Understanding the difference between VLF and Megger is vital for ensuring safe, reliable electrical installations. VLF testing uses low-frequency AC voltage to accurately assess insulation performance under realistic conditions, making it ideal for high-voltage cables. Megger testing, using DC voltage, remains invaluable for quick insulation resistance checks in motors, transformers, and low-voltage systems.

Know more about IEC Standard for Generator Protection – Key Guidelines and Compliance Requirements

In summary, VLF testing offers deep diagnostic insights and long-term reliability assurance, while Megger testing provides simplicity and speed for regular maintenance tasks. Selecting the right method ensures better insulation health monitoring and reduces the risk of unexpected electrical failures.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#VLFTesting, #MeggerTest, #CableTesting, #HighVoltageTesting, #ElectricalMaintenance, #InsulationTesting, #PowerCableTesting, #DielectricTesting, #ElectricalEngineering, #TestingEquipment, #HVTesting, #VLFvsMegger, #ElectricalSafety, #TransformerTesting, #PreventiveMaintenance