Difference Between Relay and Contactor: 7 Powerful Reasons This Guide Makes It Easy

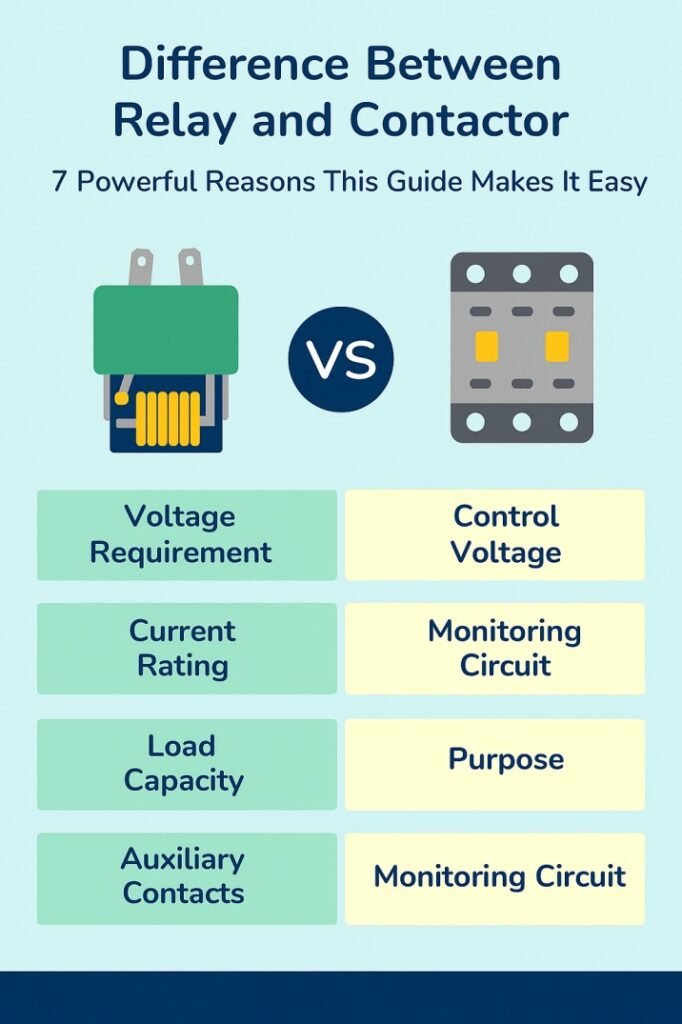

Understanding the Difference Between Relay and Contactor is important for anyone working with electrical panels, automation systems, or power distribution. Both devices control circuits. Both respond to signals. Both switch loads. Yet their functions, designs, and applications are not the same.

Many technicians mix them up because they look similar. But knowing how each device works helps you select the right one for your system. This guide explains the Difference Between Relay and Contactor in a simple and friendly way. You will learn how they operate, where they fit in electrical systems, and why choosing the correct one improves safety.

Table of Contents

This article shares seven powerful reasons that make the Difference Between Relay and Contactor easy to understand. Tables help you compare key features and boost clarity. By the end, you will know exactly which device is right for your application.

What Are Relays?

A relay is an electrically operated switch. It has a coil and contacts. When the coil energizes, the contacts open or close. Relays work in control circuits where signals are low. They are common in automation, electronics, and protection systems.

Relays are compact. They switch low power. They carry small loads like signals, sensors, control logic, and communication lines. They also provide isolation between control and power circuits.

Know more about Working Principle of an Earth Fault Relay: How It Protects Electrical Systems

What Are Contactors?

A contactor is a heavy-duty switch. It is also coil-operated, but it handles high current loads. Contactors are used in power circuits. They control motors, heaters, pumps, compressors, and large three-phase equipment.

Contactors are bigger than relays. They include arc suppression, stronger terminals, and safety accessories. Their design supports repeated switching under heavy current.

Quick Comparison Table

The table below shows the core Difference Between Relay and Contactor in a simple layout.

| Feature | Relay | Contactor |

|---|---|---|

| Main Use | Control circuits | Power circuits |

| Load Capacity | Low | Medium to high |

| Applications | Signals, logic, sensing | Motors, heaters, pumps |

| Size | Small | Larger |

| Contacts | NO, NC | Mostly NO |

| Safety Features | Basic | Arc suppression, auxiliaries |

| Voltage Switching | Low to moderate | High voltage and high current |

Why the Difference Between Relay and Contactor Matters

Understanding the Difference Between Relay and Contactor ensures proper system selection. An incorrect device can fail under load or cause overheating. Using the right device improves performance, safety, and reliability. The next seven reasons make the distinction simple.

Know more about IEC Standards for Transformer Testing – Complete Guide to IEC 60076 and Testing Procedures

1. Purpose of Operation Is Completely Different

A relay switches signals. It works where the current is small. It sends commands to other devices. It acts like a messenger in the system.

A contactor switches power. It controls main loads. It starts motors. It handles high current without damage.

This difference in purpose is the first clear Difference Between Relay and Contactor every technician should know.

2. Load Capacity Separates Them Clearly

Relays handle small loads. Examples include sensors, alarms, PLC signals, and small DC circuits.

Contactors handle large loads. Examples include three-phase motors, industrial heaters, and large pumps.

When choosing between them, load size is the strongest indicator. Using a relay where a contactor is required leads to rapid failure. This is another strong Difference Between Relay and Contactor you should remember.

3. Safety Features Are Not the Same

Relays are simple devices with basic insulation and no arc suppression. They are not designed for high-energy switching.

Contactors include arc chutes, better terminals, and protective accessories. They are built to handle electrical stress safely.

This makes safety a major Difference Between Relay and Contactor during equipment selection.

Know more about IEC Standard for Vacuum Circuit Breaker – IEC 62271 Guidelines, Ratings & Testing Explained

4. Contact Structure and Design Vary a Lot

Relays include NO and NC contacts. They are used for both energizing and de-energizing tasks. They allow complex control logic.

Contactors usually have only NO power contacts. This design prevents accidental power flow. They may include auxiliary contacts for control logic.

This structural design difference is another key Difference Between Relay and Contactor that impacts real-world applications.

5. Durability and Life Expectancy Are Different

Relays are built for small, frequent switching in low-power circuits. Their life is long but only under light load.

Contactors are built for heavy switching. They manage high inrush currents. They withstand heat and repeated cycles under stress.

This durability factor creates a practical Difference Between Relay and Contactor in industrial design.

6. Voltage Handling Capability Sets Them Apart

Relays handle small AC or DC voltages. They operate in logic circuits, PLC outputs, and signal processing sections.

Contactors handle high AC voltages. They manage the startup current of induction motors and resistive heating elements. They operate in main distribution boards.

This voltage difference is an essential Difference Between Relay and Contactor for safe system operation.

Know more about Difference Between VLF and Megger: Best Guide and Applications

7. Applications Clearly Define the Device Required

Relays fit into control systems, communication circuits, automation panels, and electronics.

Contactors fit into motor control centers, industrial plants, HVAC systems, and power distribution setups.

When you study the applications, the Difference Between Relay and Contactor becomes obvious. Each device serves a unique segment of the electrical system.

Comparison Table: Technical Specifications

This table highlights more details that boost your understanding.

| Parameter | Relay | Contactor |

|---|---|---|

| Coil Voltage | 5V to 230V | 24V to 230V |

| Current Rating | 1A to 20A | 9A to 1000A+ |

| Arc Suppression | Not common | Standard feature |

| Usage Frequency | High for small loads | High for heavy loads |

| Control Logic | Yes | Auxiliary-based |

| Back-EMF Protection | Often required | Built-in or optional |

How to Choose Between Relay and Contactor

Choosing between the two depends on the load type and safety needs. Always check the voltage, current, duty cycle, and circuit function. For motors, heaters, and heavy machinery, always pick a contactor. For signals, low-current automation, or logic tasks, pick a relay.

Understanding the Difference Between Relay and Contactor makes this selection simple. The wrong choice leads to contact burning, overheating, and equipment failure. The right choice ensures long life and stable operation.

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

Final Thoughts

The Difference Between Relay and Contactor is easy once you know their purpose, capacity, and structure. Relays work in control circuits. Contactors work in power circuits. Both devices play important roles, but they are not interchangeable. When you understand these seven powerful reasons, choosing the right device becomes simple, safe, and reliable.

If you apply these insights to your electrical systems, you will avoid common mistakes. You will also improve performance and reduce maintenance costs. Knowing the Difference Between Relay and Contactor helps you design better panels and more efficient industrial setups.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#relayvscontactor, #electricalengineering, #powerdistribution, #controlsystems, #industrialautomation, #electricalsafety, #motorcontrol, #engineeringbasics, #electricalcomponents, #techknowledge