Cable Bus vs Bus Duct: Complete Comparison, Advantages & Best Applications

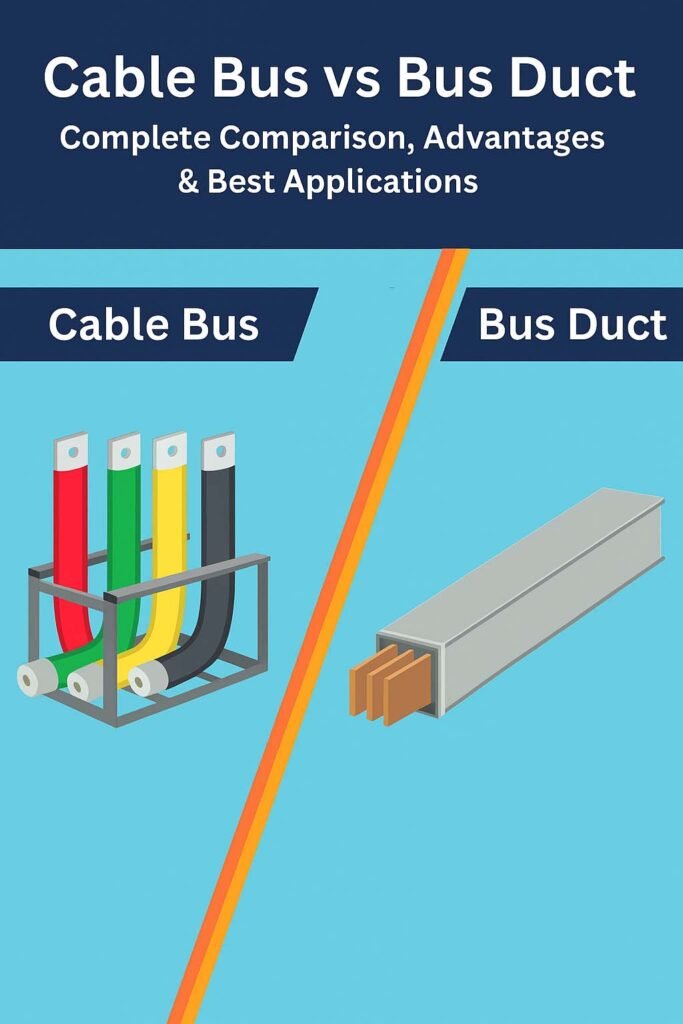

Understanding the difference between a cable bus and a bus duct is important when designing electrical distribution systems for industrial, commercial, or utility projects. Many engineers search for clear guidance on cable bus vs bus duct because both systems look similar at first glance.

Table of Contents

Yet their construction, installation method, performance, and long-term reliability are different. This detailed guide explains these differences in simple language. It includes practical examples, technical insights, and real-world considerations to help you select the right system for your project.

Cable Bus vs Bus Duct: What Makes Them Different

Cable bus is an open or ventilated power distribution system that uses multiple parallel conductors arranged in a tray-like structure. The cables are mounted with proper spacing to ensure balanced impedance and reduced heating. On the other hand, a bus duct is an enclosed system where busbars carry power inside a metal casing. This difference in structure leads to variations in performance, cooling, safety, price, and installation. Use our online tool 3 phase cable size calculator

Cable bus systems are flexible. They can route easily around bends. They reduce fault stress by spreading current across multiple parallel cables. Bus duct systems are compact and rigid. They offer a clean structural appearance. They are commonly used in commercial buildings where space and aesthetics matter.

When comparing cable bus vs bus duct, the choice depends on load current, installation environment, mechanical strength, and future expansion needs. Both systems have strengths. Both can handle high ampere ratings. But the right option depends on the project’s priorities. Try our free online tool today ev charger cable size calculator

Construction Differences in Cable Bus vs Bus Duct

Cable bus consists of insulated power cables laid on a support structure. These supports maintain proper spacing. The system remains ventilated, allowing heat to escape easily. The cables are standard power cables, making replacement and extension easier.

Explore our professional online tool for quick calculations kw to cable size calculator

Bus duct uses rigid copper or aluminum busbars. These conductors are installed inside a grounded metal housing. The system may also include tap-offs, elbows, and special fittings. Bus ducts often require factory-made sections because customization on-site is limited. Access our powerful online calculator now star delta motor cable size calculator

Here is a comparison table that shows the construction differences clearly:

Construction Comparison Table

| Feature | Cable Bus | Bus Duct |

|---|---|---|

| Conductor Type | Parallel power cables | Rigid copper or aluminum busbars |

| Structure | Open or ventilated | Fully enclosed metal housing |

| Heat Dissipation | Natural ventilation | Limited ventilation |

| Flexibility | High | Low |

| Customization | Easy on-site | Mostly factory-built |

Installation Factors in Cable Bus vs Bus Duct

Cable bus installation is straightforward. Installers route cables within the support system. The system is adaptable around corners and obstacles. Since standard power cables are used, local availability is high and lead times are short.

Bus duct installation is more complex. Each section must be aligned properly. Misalignment can cause mechanical stress. The rigid structure needs careful planning. Fittings must be ordered in advance, especially for non-standard angles.

Cable bus allows long continuous runs. Bus ducts usually come in fixed lengths. Transportation and handling can also be challenging due to weight. Get instant results with our online tool earth cable size calculator

Installation Comparison Table

| Factor | Cable Bus | Bus Duct |

|---|---|---|

| Installation Complexity | Low | Medium to High |

| Required Space | More due to spacing | Less due to compact body |

| Flexibility During Routing | Excellent | Limited |

| On-Site Modifications | Easy | Difficult |

Performance Differences in Cable Bus vs Bus Duct

A major reason engineers compare cable bus vs bus duct is their performance under high current and fault conditions. Cable bus distributes current over multiple cables. This reduces the thermal stress during faults. The system stays cooler due to ventilation.

Bus duct, however, offers strong mechanical protection. The enclosure shields the conductors from environmental damage. Fault currents are handled by strong busbars and insulated housing.

Cable bus systems typically provide better heat dissipation and lower operating temperatures. Bus ducts offer enhanced short-circuit strength. Engineers choose based on priorities like cooling, durability, and system size. Start using our easy-to-use online tool earthing cable size calculator

Performance Comparison Table

| Parameter | Cable Bus | Bus Duct |

|---|---|---|

| Heat Management | Excellent | Moderate |

| Short-Circuit Strength | Moderate to High | High |

| Mechanical Protection | Medium | Very High |

| Maintenance Needs | Low | Medium |

Cost Differences Between Cable Bus vs Bus Duct

Cable bus is usually more cost-effective for long runs and high ampacity applications. The use of standard cables reduces material cost. Installation cost is also lower due to easier handling.

Bus ducts cost more. They require custom fabrication, precise installation, and heavier fittings. But in high-rise buildings or tight spaces, their compact size reduces structural cost.

Make your task simple with our online tool electrical cable size calculator

Cable bus is favored for substations, power plants, and large industrial facilities. Bus ducts are preferred in malls, office towers, factories, and commercial settings.

Reliability and Maintenance in Cable Bus vs Bus Duct

Cable bus has fewer points of failure. Each cable is independent, so a single conductor failure does not collapse the entire system. Inspection is simple because the system is visible and accessible.

Bus duct offers a protected design. But failures inside the enclosure may not be visible. In some cases, overheating or insulation issues remain hidden.

Cable bus systems offer easy expansion. Adding more cables or replacing damaged ones is simple. Bus duct modifications require new sections from the manufacturer. Calculate instantly with our smart online tool cable size calculator australia

When to Choose Cable Bus vs Bus Duct

Choose cable bus when your priority is ventilation, long runs, reduced installation cost, and easy expansion. It works well in power plants, industrial plants, renewable energy stations, and transformer to switchgear connections.

Choose bus duct when you need compact routing, high mechanical security, and a clean appearance. It is ideal for commercial buildings, data centers, and manufacturing floors.

Final Thoughts on Cable Bus vs Bus Duct

The comparison of cable bus vs bus duct shows that both systems have strong advantages. Neither option is right for every project. Cable bus gives better cooling, lower costs, and easier modifications. Bus duct gives stronger protection, compact design, and clean routing. Your final choice should depend on electrical load, installation environment, available space, and long-term maintenance plans. When selected correctly, both systems provide safe and reliable power distribution for many years. Experience fast and accurate results using our online tool cable size calculator uk

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#CableBusVsBusDuct, #CableBus, #BusDuct, #ElectricalSystems, #PowerDistribution, #IndustrialElectrical, #IECStandards, #NECStandards, #ElectricalDesign, #PowerEngineering, #ElectricalSafety, #CableTray, #BuswaySystem, #ElectricalInstallation, #EngineeringComparison