Best PLC Programming Software 2026 – Top Tools Compared for Faster Automation Projects

Choosing the best PLC programming software in 2026 is no longer a simple decision. Automation systems are becoming more complex, projects are more time-sensitive, and industries expect faster commissioning with fewer errors. A good PLC software platform now directly impacts productivity, troubleshooting time, and long-term maintenance costs.

This guide is written from a practical automation engineering perspective. It compares leading PLC programming tools used globally in manufacturing, process industries, utilities, and renewable energy projects. If you are an electrical engineer, automation technician, or system integrator, this article will help you select the right tool based on real-world usage, not marketing claims.

Table of Contents

What Defines the Best PLC Programming Software in 2026

Before comparing tools, it is important to understand what makes a PLC platform stand out today. The best PLC programming software is not only about brand popularity. It must support modern automation workflows and engineering efficiency.

Know more about Remote Monitoring with PLC and IoT Integration

Key evaluation factors include

• Compliance with IEC 61131-3 programming standards

• Support for ladder logic, function block, structured text, and SFC

• Simulation and offline testing capabilities

• Integration with SCADA, HMI, and industrial networks

• Licensing cost and long-term scalability

• Ease of debugging and diagnostics

Engineers now prefer software that reduces development time and simplifies maintenance across multi-vendor environments.

Top PLC Programming Software Compared for 2026

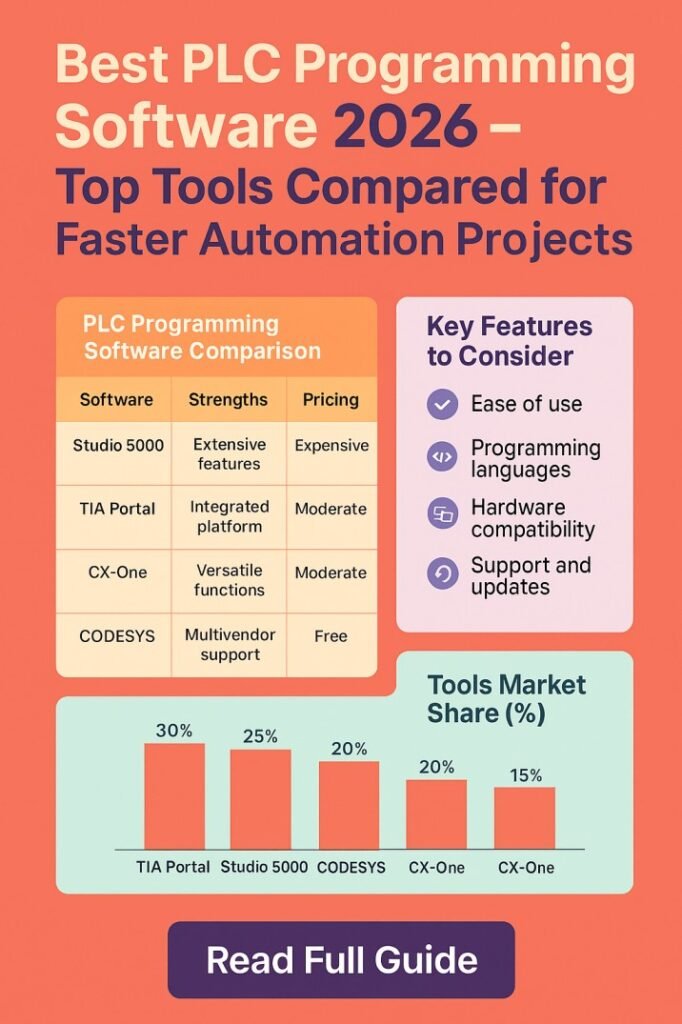

The following table provides a high-level comparison of the most widely used PLC platforms in industrial automation.

| PLC Software | Manufacturer | Supported Languages | Best Use Case | Skill Level |

|---|---|---|---|---|

| TIA Portal | Siemens | LAD, FBD, STL, SCL | Large industrial plants | Intermediate to Advanced |

| Studio 5000 | Rockwell Automation | LAD, FBD, ST, SFC | North American factories | Advanced |

| EcoStruxure Control Expert | Schneider Electric | LD, FBD, ST, IL | Process and energy systems | Advanced |

| GX Works3 | Mitsubishi Electric | LAD, FBD, ST | High-speed machine control | Intermediate |

| CX-Programmer | Omron | Ladder, ST | Packaging and robotics | Intermediate |

| Codesys | Codesys GmbH | All IEC 61131-3 | Vendor-neutral automation | Beginner to Advanced |

Each of these platforms qualifies as best PLC programming software for specific project types. The sections below explain them in detail.

Know more about Top SCADA Software Platforms for Energy Sector

Siemens TIA Portal

Siemens TIA Portal remains a strong choice in 2026 for integrated automation systems. It combines PLC programming, HMI configuration, drive control, and diagnostics in a single environment.

TIA Portal supports modular programming and advanced structured text, making it suitable for complex industrial applications. Engineers working with Siemens S7-1200 and S7-1500 controllers benefit from powerful debugging and system diagnostics.

Advantages include

• Seamless PLC and HMI integration

• Strong hardware diagnostics

• Excellent support for industrial networking

Limitations include higher licensing costs and a steeper learning curve for beginners.

For large projects, TIA Portal continues to be considered among the best PLC programming software options available. Know more about PLC Programming Salary 2026 – Experience-Wise Pay, Country Comparison & Skills That Boost Income

Rockwell Studio 5000 Logix Designer

Studio 5000 is the standard PLC software for Allen-Bradley controllers. It is widely used in automotive, food processing, and pharmaceutical plants, especially in North America.

The software emphasizes tag-based programming and modular design. It works closely with FactoryTalk SCADA systems, making it ideal for Rockwell-centric automation environments.

Key strengths

• Powerful motion control integration

• Reliable online editing

• Strong ecosystem support

However, Studio 5000 licensing is expensive, and hardware dependency limits flexibility. Still, for Rockwell systems, it remains one of the best PLC programming software choices.

Schneider EcoStruxure Control Expert

Formerly known as Unity Pro, EcoStruxure Control Expert is widely used in process automation and energy systems. It supports complex control strategies and high-availability architectures.

The software is preferred in oil and gas, water treatment, and power generation facilities where reliability is critical.

Notable features

• Advanced process control functions

• High-performance redundancy support

• Strong cybersecurity integration

Know more about HMI vs SCADA: Which System Should You Choose?

Its interface is less intuitive for new engineers, but experienced users consider it one of the best PLC programming software tools for mission-critical applications.

Mitsubishi GX Works3

GX Works3 is designed for Mitsubishi iQ-R and iQ-F PLC series. It is optimized for high-speed control and machine automation.

The software provides excellent motion control and real-time monitoring features. It is commonly used in robotics, CNC systems, and packaging machinery.

Benefits include

• Fast program execution

• Compact project structure

• Efficient troubleshooting tools

GX Works3 may feel restrictive outside Mitsubishi hardware, but within its ecosystem, it ranks among the best PLC programming software options.

Omron CX-Programmer

CX-Programmer remains popular in mid-scale automation projects, especially in Asia and Europe. It offers reliable ladder logic programming with good simulation features.

Omron software is known for its stability and ease of maintenance, making it suitable for packaging lines and assembly systems.

Highlights

• Simple ladder logic interface

• Strong PLC-HMI communication

• Lower learning curve

While not as modern as some platforms, it still qualifies as best PLC programming software for medium complexity systems.

Know more about Industrial IoT Sensors in Automation: Cost and Integration

Codesys – Vendor-Neutral PLC Programming

Codesys stands out in 2026 due to its hardware-independent architecture. Many PLC manufacturers use Codesys as their core programming platform.

It fully supports IEC 61131-3 languages and is widely used in IIoT and Industry 4.0 applications.

Why engineers prefer Codesys

• Works across multiple PLC brands

• Excellent structured text support

• Cost-effective licensing

For engineers seeking flexibility, Codesys is often considered the best PLC programming software for long-term scalability.

Feature Comparison for Faster Automation Projects

The table below compares productivity-focused features that impact project delivery speed.

| Feature | TIA Portal | Studio 5000 | EcoStruxure | GX Works3 | Codesys |

|---|---|---|---|---|---|

| Offline Simulation | Yes | Limited | Yes | Yes | Yes |

| Structured Text Power | High | High | High | Medium | Very High |

| Multi-Vendor Support | No | No | Limited | No | Yes |

| Learning Curve | Medium | High | High | Medium | Low to Medium |

| Cost Efficiency | Medium | Low | Medium | Medium | High |

This comparison helps identify the best PLC programming software based on engineering efficiency rather than brand loyalty.

Know more about OPC UA vs MQTT: Protocol Comparison for Industrial Control

How to Choose the Right PLC Software in 2026

Selecting the right platform depends on project scope and future expansion plans. Consider these practical guidelines

• Match software with installed PLC hardware

• Evaluate long-term licensing costs

• Consider availability of skilled engineers

• Ensure SCADA and network compatibility

The best PLC programming software is the one that aligns with both technical and business requirements.

Final Verdict

In 2026, there is no single universal winner. Siemens TIA Portal and Rockwell Studio 5000 dominate large industrial plants. Schneider and Mitsubishi excel in process and machine automation. Codesys leads in flexibility and future-ready automation.

Know more about Modbus Communication Protocol: Master-Slave Explained

Engineers who prioritize faster commissioning, easier troubleshooting, and scalable design will benefit most by carefully matching their project needs with the best PLC programming software available today.

A well-chosen PLC platform not only speeds up automation projects but also reduces lifecycle costs and improves system reliability for years to come.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BestPLCProgrammingSoftware2026, #PLCSoftware2026, #PLCProgrammingTools, #IndustrialAutomation, #AutomationSoftware, #PLCDevelopment, #SCADASoftware, #ControlSystems, #ElectricalEngineering, #AutomationEngineers