Hysteresis Loss and Eddy Current Loss: Important Differences

Difference between Hysteresis loss and eddy current loss can be simplified by understanding the types of losses. Hysteresis loss and eddy current loss are two distinct mechanisms of energy dissipation in different situations.

Find Differences Below

Let’s explore the differences between these two types of losses in detail:

Cause and Mechanism

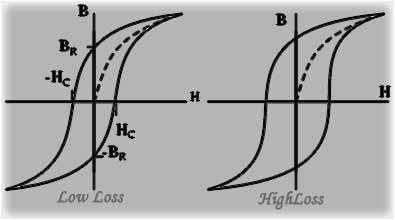

Hysteresis Loss: Hysteresis loss occurs in ferromagnetic materials when they are subjected to cyclic magnetic fields. It is primarily caused by the lag or delay in the alignment and realignment of the magnetic domains within the material with the changing magnetic field.

This lag results in energy dissipation as heat due to the internal friction and resistance within the material as the domains undergo repeated magnetic polarization.

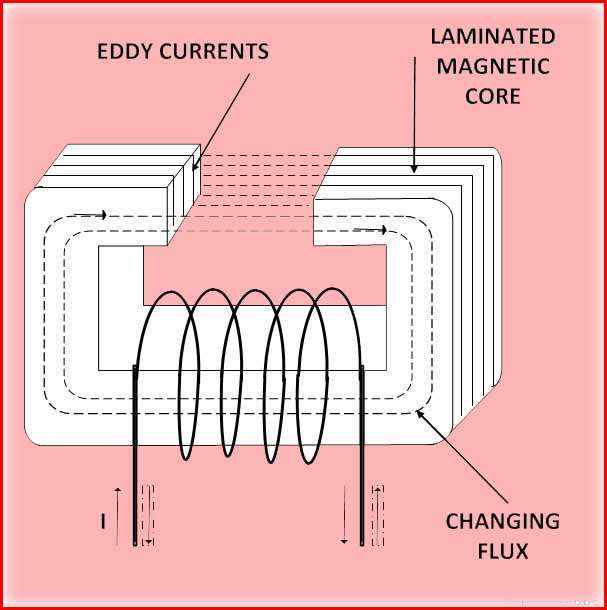

Eddy Current Loss: Eddy current loss, on the other hand, is induced by the presence of changing magnetic fields and occurs in conductive materials. When a conductor is exposed to a varying magnetic field, circulating currents, known as eddy currents, are generated within the conductor.

These eddy currents encounter resistance, leading to Joule heating and the dissipation of energy as heat.

Nature of Materials

Hysteresis Loss: Hysteresis loss occurs specifically in ferromagnetic materials, such as iron and its alloys. These materials possess a unique property called hysteresis, characterized by the lag in magnetization during changes in the external magnetic field.

Eddy Current Loss: Eddy current loss can occur in any conductive material, including both ferromagnetic and non-ferromagnetic materials. The magnitude of eddy current loss depends on the electrical conductivity of the material, with higher conductivity resulting in larger eddy currents and consequently higher losses.

Time Dependency

Hysteresis Loss: Hysteresis loss is dependent on the frequency and magnitude of the changing magnetic field. As the frequency increases or the magnetic field changes more rapidly, the hysteresis loss tends to increase.

Eddy Current Loss: Eddy current loss is directly proportional to the frequency of the varying magnetic field. Higher frequencies result in larger eddy currents and, subsequently, increased energy dissipation.

Mitigation Techniques

Hysteresis Loss: To reduce hysteresis loss, materials with low coercivity (ability to resist magnetization) are typically chosen, such as silicon steel or ferrites, for applications where hysteresis loss needs to be minimized. These materials have a narrower hysteresis loop, indicating lower energy dissipation during each cycle.

Eddy Current Loss: Eddy current losses can be mitigated using various techniques. Laminated cores are commonly used in transformers and electrical machines to confine eddy currents to individual layers, reducing their magnitude and associated losses. Additionally, the use of magnetic materials with high electrical resistivity, such as ferrites, can minimize eddy current losses by limiting the magnitude of the circulating currents.

In summary, hysteresis loss and eddy current loss are distinct mechanisms of energy dissipation occurring in different materials and under different circumstances. Hysteresis loss is specific to ferromagnetic materials and is caused by the lag in magnetization during cyclic magnetic field changes. Eddy current loss, on the other hand, occurs in conductive materials due to the generation of circulating currents induced by changing magnetic fields. Understanding these differences between Hysteresis loss and eddy current loss is crucial for designing efficient electrical systems and optimizing energy utilization. Discover more topics below to understand the transformer losses in detail.

More Related Posts:

- What is Hysteresis loss?

- Eddy Current Loss: Important Application

- Transformers: Important Types, Features

- Transformer Oil Testing: 9 Important Tests

- 10 Transformer Tests Before Commissioning

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.