Bus Bar Current Rating Calculation: Practical Method for Accurate Sizing and Load Capacity

Introduction

Busbars carry the full load current inside switchboards, distribution panels, and motor control centers. A wrong size selection can cause overheating, voltage drop, insulation damage, and even shutdown of critical equipment. This is why every engineer must understand the bus bar current rating calculation process and apply it with practical field considerations.

Table of Contents

A reliable bus bar current rating calculation ensures that the conductor can safely handle the expected load without exceeding the allowable temperature rise. It also helps optimize material cost while maintaining long-term reliability. Instead of depending only on thumb rules, engineers should combine standards, temperature limits, and installation conditions.

Find all about Busbar Bending Calculation

Understanding Busbar Current Carrying Capacity

The current carrying capacity of a busbar depends mainly on its cross-sectional area, material, cooling conditions, and permissible temperature rise. Copper and aluminum are the most common materials used because of their conductivity and mechanical strength.

When performing a bus bar current rating calculation, the designer must check how heat is generated due to I²R losses and how effectively it dissipates into the surrounding air. If heat removal is poor, even a large busbar can fail under continuous load.

Key factors that influence ampacity include:

- Busbar material conductivity

- Ambient temperature inside the panel

- Mounting arrangement and spacing

- Surface finish and plating

- Ventilation or forced cooling

Ignoring any of these can result in underestimating the required size during bus bar current rating calculation.

Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

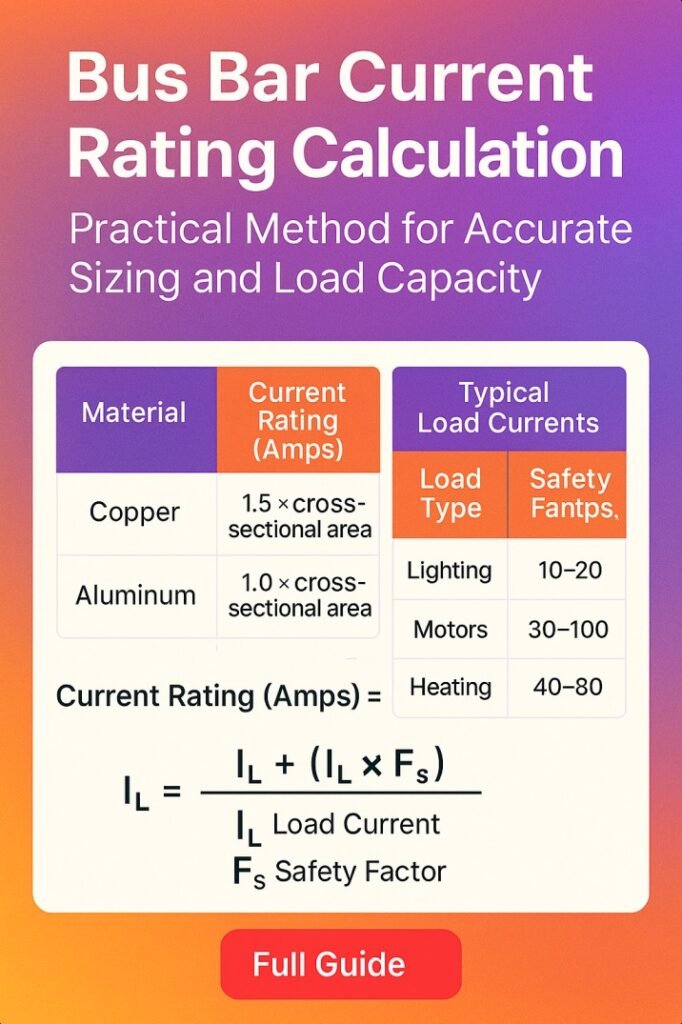

Material Comparison for Busbars

Copper busbars offer higher conductivity and better short circuit withstand capability. Aluminum busbars are lighter and cost effective but require larger cross section for the same current.

| Property | Copper Busbar | Aluminum Busbar |

|---|---|---|

| Conductivity | Very High | Moderate |

| Mechanical Strength | High | Medium |

| Cost | Higher | Lower |

| Corrosion Resistance | Good | Needs protection |

| Required Cross Section | Smaller | Larger |

During bus bar current rating calculation, material selection directly affects the final dimensions and installation cost.

Standard Current Density Method

A practical approach used by panel manufacturers is the current density method. Current density is defined as current per unit cross-sectional area of the busbar.

Typical design values:

| Busbar Material | Current Density (A/mm²) | Application Condition |

|---|---|---|

| Copper | 1.2 – 1.6 | Enclosed panel |

| Copper | 1.6 – 2.0 | Open air |

| Aluminum | 0.8 – 1.2 | Enclosed panel |

| Aluminum | 1.0 – 1.4 | Open air |

Using this table, engineers can quickly perform an initial bus bar current rating calculation before refining the design with temperature rise verification.

Find out more about High Impedance Busbar Protection Explained with Example Calculations

Step-by-Step Practical Calculation Example

Assume a panel requires a continuous load current of 1600 A using copper busbars in an enclosed switchboard.

- Select a conservative current density of 1.4 A/mm².

- Required cross-sectional area:

Area = Current / Current Density

Area = 1600 / 1.4

Area ≈ 1143 mm²

- Choose a standard busbar size combination such as:

50 mm × 10 mm = 500 mm² per bar

Using three parallel bars gives 1500 mm² total.

This method ensures the bus bar current rating calculation remains practical and includes a safety margin.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Temperature Rise and Heat Dissipation Check

After selecting the physical size, the next step is to confirm that the busbar temperature does not exceed the permissible limit, usually 70°C to 90°C depending on insulation class.

Heat generation depends on resistance, which decreases with larger cross-section. Proper spacing between phases improves air circulation and heat dissipation.

Factors improving cooling:

- Vertical mounting orientation

- Adequate clearance between phases

- Ventilated enclosure

- Tin plating to reduce oxidation

A refined bus bar current rating calculation always verifies temperature rise under continuous load conditions.

Effect of Installation Conditions

Busbars installed in compact panels experience reduced heat dissipation. Grouping multiple bars closely also increases temperature.

Correction factors are often applied:

| Installation Condition | Derating Factor |

|---|---|

| Poor Ventilation | 0.85 |

| High Ambient (45°C+) | 0.90 |

| Multiple Bars in Close Spacing | 0.95 |

Adjusted current capacity = Rated Current × Derating Factor

Including these corrections makes the bus bar current rating calculation more accurate for real operating environments.

Find out more about iec 61439 busbar clearance

Voltage Drop Consideration

Although busbars are short conductors, high current flow can still produce measurable voltage drop. Maintaining low resistance helps improve system efficiency.

Voltage drop can be estimated using:

Voltage Drop = I × R

Where resistance depends on length, material resistivity, and cross-sectional area. Increasing thickness or adding parallel bars reduces losses. A well executed bus bar current rating calculation ensures both thermal and electrical performance remain within limits.

Short Circuit Withstand Capability

Electrical Busbars must survive fault currents for a specified duration, usually 1 second. Mechanical forces during short circuit conditions can bend or damage inadequately sized bars.

Short circuit withstand current depends on:

- Material strength

- Support spacing

- Busbar thickness

Engineers often verify the electrodynamic stress after completing the bus bar current rating calculation so the system remains safe during faults.

Get complete information about iec standard for busbar sizing

Common Mistakes in Busbar Sizing

Even experienced designers sometimes rely on oversimplified rules. Typical errors include:

- Ignoring enclosure temperature rise

- Selecting aluminum without increasing cross section

- Not applying derating for grouped bars

- Overlooking short circuit forces

Avoiding these mistakes improves the reliability of every bus bar current rating calculation performed for industrial panels.

Recommended Practical Selection Guide

The following quick reference helps during preliminary design:

| Load Current (A) | Suggested Copper Busbar Size |

|---|---|

| 400 A | 25 × 5 mm |

| 800 A | 40 × 5 mm |

| 1600 A | 50 × 10 mm (multiple bars) |

| 2500 A | 80 × 10 mm (parallel arrangement) |

This guide should always be validated with a detailed bus bar current rating calculation before final approval.

Read in detail about iec 61439 busbar calculation

Final Thoughts

Accurate busbar sizing is essential for safe and efficient power distribution. Engineers must evaluate current density, temperature rise, ventilation, and fault withstand capability before selecting dimensions. A structured bus bar current rating calculation prevents overheating, reduces energy losses, and extends equipment life.

By combining standard tables with real installation conditions, designers can achieve the correct balance between performance and cost. In modern electrical panels, attention to detail during bus bar current rating calculation directly translates into higher reliability and fewer maintenance issues over the equipment lifecycle. Know more about IEC Standard for Busbar Clearance

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BusBarCurrentRatingCalculation, #BusbarSizing, #ElectricalDesign, #SwitchgearEngineering, #AmpacityCalculation, #PowerDistribution, #PanelDesign, #ElectricalEngineering, #BusbarSelection, #LoadCalculation