IEC Standard for Lead Acid Battery: Essential Compliance Rules Engineers Often Miss

The IEC standard for lead acid battery systems plays a critical role in ensuring safety, reliability, and long service life in industrial, commercial, and utility applications. Yet, many engineers treat these standards as a formality rather than a technical guide that influences real-world performance. From telecom power rooms and substations to UPS systems and renewable energy storage, compliance gaps often appear during installation, testing, or maintenance rather than during design.

Table of Contents

Understanding how the IEC standard for lead acid battery applies across the full battery lifecycle helps engineers avoid hidden risks, premature failures, and costly non-compliance issues. This article explains the most relevant IEC requirements, the intent behind them, and the compliance rules that are frequently overlooked in practice.

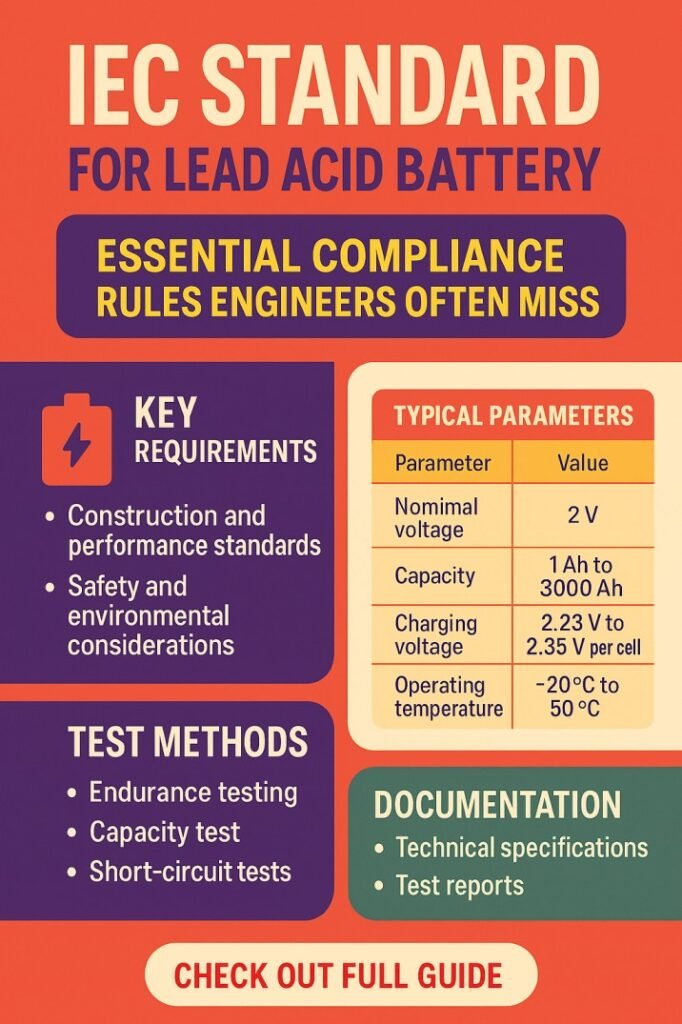

What the IEC Standard for Lead Acid Battery Covers

The IEC standard for lead acid battery is not a single document. It is a family of standards developed by the International Electrotechnical Commission to regulate construction, performance, testing, safety, and installation practices.

These standards apply to both vented and valve regulated lead acid batteries, including AGM and gel types. They cover stationary batteries, industrial batteries, and batteries used in standby power systems.

The most commonly referenced IEC documents include IEC 60896, IEC 61056, IEC 62485, and IEC 61427. Each standard addresses a different technical aspect, but together they define how a compliant lead acid battery system should be designed and operated.

Explore details on ev battery degradation calculator

Key IEC Standards Engineers Should Know

The table below summarizes the most relevant documents associated with the IEC standard for lead acid battery applications.

| IEC Standard | Primary Focus | Typical Application |

|---|---|---|

| IEC 60896 | Stationary lead acid batteries | Substations, UPS, telecom |

| IEC 61056 | General purpose VRLA batteries | Small UPS, control panels |

| IEC 62485 | Safety requirements for battery installations | Battery rooms, enclosures |

| IEC 61427 | Batteries for renewable energy storage | Solar and hybrid systems |

| IEC 60254 | Industrial traction batteries | Forklifts, industrial equipment |

Engineers often reference IEC 60896 for capacity and performance but forget to apply IEC 62485 during layout and ventilation planning, which leads to safety violations. Know more about EV Battery Types Explained for Professionals: Standards, Safety, Costs, and Performance Comparison

Compliance Rule Engineers Often Miss: Installation Environment

One of the most overlooked areas of the IEC standard for lead acid battery compliance is the installation environment. IEC standards specify limits for ambient temperature, humidity, and ventilation to prevent thermal runaway and accelerated aging.

Many battery rooms operate continuously above 25°C. According to IEC guidance, every 10°C rise above nominal temperature can reduce battery life by nearly 50 percent. This is not just a performance issue; it directly affects warranty validity and compliance.

Ventilation requirements are also frequently ignored, especially for VRLA batteries. Even sealed batteries release hydrogen under fault or overcharge conditions. IEC 62485 defines minimum air flow rates based on battery capacity and charging current, but these calculations are rarely documented during commissioning.

Charging and Float Voltage Misinterpretation

Another common compliance gap relates to charging parameters. The IEC standard for lead acid battery clearly defines acceptable ranges for float voltage, equalization voltage, and ripple current.

Engineers often rely on manufacturer defaults without verifying alignment with IEC limits. Excessive float voltage may pass short-term acceptance tests but causes long-term grid corrosion and water loss.

The following table shows typical IEC-aligned voltage ranges for stationary lead acid batteries at 20°C.

| Battery Type | Float Voltage per Cell | Equalization Voltage per Cell |

|---|---|---|

| Vented Lead Acid | 2.23 – 2.25 V | 2.35 – 2.40 V |

| VRLA AGM | 2.25 – 2.30 V | 2.35 – 2.38 V |

| VRLA Gel | 2.23 – 2.27 V | Limited or manufacturer defined |

Failure to temperature-compensate these voltages is another missed rule. IEC standards expect voltage adjustment based on ambient temperature, especially in outdoor or non-air-conditioned sites.

Explore everything about Electric Vehicle Battery Replacement Cost: Real Prices, Lifespan & Smart Savings in 2026

Testing and Capacity Verification Gaps

The IEC standard for lead acid battery defines strict testing methods for capacity verification, including discharge rate, end voltage, and rest periods. However, field testing often deviates from these requirements due to time constraints.

Many engineers perform shortened discharge tests or skip stabilization periods after charging. While this may provide a rough indication of battery health, it does not meet IEC compliance criteria.

IEC 60896 specifies that capacity tests must be conducted at a defined discharge rate, typically C10 or C20, depending on application. End voltage must be monitored per cell, not just at the string level. Ignoring these details can lead to incorrect conclusions about battery condition.

Safety Labeling and Documentation Oversights

Documentation is a silent but critical part of IEC standard for lead acid battery compliance. IEC 62485 requires clear labeling of battery voltage, short-circuit current, hazard warnings, and personal protective equipment requirements.

In many installations, battery racks lack proper signage, and emergency procedures are not displayed. Engineers may assume that safety training compensates for missing labels, but IEC compliance requires physical identification and warning systems. Know more about Why Are Lithium Batteries Dangerous: 7 Hidden Risks You Must Know

Maintenance records are another weak point. IEC standards expect traceable logs for inspections, voltage readings, and corrective actions. Missing or incomplete records can invalidate compliance during audits or incident investigations.

Intercell Connections and Torque Control

Mechanical compliance is often underestimated. The IEC standard for lead acid battery includes guidance on intercell connections, conductor sizing, and tightening torque.

Loose or over-tightened connections increase contact resistance, leading to localized heating and uneven charging. Many failures attributed to battery defects are actually caused by improper torque control during installation.

IEC guidance expects calibrated torque tools and documented tightening values. Visual inspection alone does not meet the intent of the standard.

Application in Renewable Energy Systems

With the rise of solar and hybrid power systems, IEC 61427 has become increasingly important. This part of the IEC standard for lead acid battery addresses cyclic operation rather than float service.

Engineers transitioning from UPS or telecom systems often apply stationary battery assumptions to renewable installations. This mismatch results in incorrect depth of discharge limits, inadequate charge recovery, and premature capacity loss.

Know more about IEC Standard for VRLA Battery – Complete Guide to Design, Testing, and Performance

IEC 61427 emphasizes cycle life testing, partial state of charge behavior, and real load profiles. Ignoring these factors leads to systems that appear compliant on paper but fail in operation.

Why Engineers Miss These Rules

The main reason engineers miss critical IEC requirements is fragmentation. The IEC standard for lead acid battery is spread across multiple documents, each focusing on a specific discipline. Design teams, installers, and maintenance personnel often work in silos, assuming someone else has addressed compliance.

Another factor is over-reliance on manufacturer data. While datasheets are important, IEC standards provide neutral baseline requirements that apply regardless of brand.

Practical Steps to Improve IEC Compliance

To apply the IEC standard for lead acid battery effectively, engineers should integrate compliance checks into every project phase. This includes verifying environmental conditions during site surveys, documenting charging settings during commissioning, and scheduling IEC-aligned testing intervals.

Know everything about Best Solar Batteries for Tesla Powerwall Alternatives

Using standardized checklists based on IEC clauses helps bridge gaps between theory and practice. Regular training on updates to IEC standards also prevents outdated assumptions from persisting in the field.

Final Thoughts

The IEC standard for lead acid battery is more than a regulatory reference. It is a practical engineering framework designed to reduce risk, extend service life, and improve system reliability. The rules engineers often miss are not obscure technicalities but foundational requirements tied to safety and performance.

By treating IEC compliance as a continuous process rather than a one-time approval step, engineers can avoid common mistakes that lead to failures, audits, and reputational damage. A deeper understanding of these standards ultimately results in safer installations and more dependable power systems.

Here is a quick guide where you can find Best Batteries for Solar Panels in UK (2025) – Top Solar Storage Options for Homes

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard,#LeadAcidBattery,#BatterySafetyStandards,#IECCompliance,#ElectricalStandards,#PowerSystems,#BatteryTesting,#EnergyStorage,#ElectricalEngineering,#IndustrialBatteries