Transformer Tan Delta Test Procedure: Step-by-Step Guide to Ensure Insulation Health

Maintaining the health of a transformer’s insulation is crucial for the reliability and longevity of power systems. One of the most effective ways to assess insulation condition is through the transformer tan delta test procedure. This test helps engineers identify insulation deterioration, moisture content, and potential defects before they lead to catastrophic failures. In this guide, we will cover a step-by-step approach to performing a tan delta test on transformers, explaining each stage and providing practical insights for engineers.

Table of Contents

What is the Transformer Tan Delta Test?

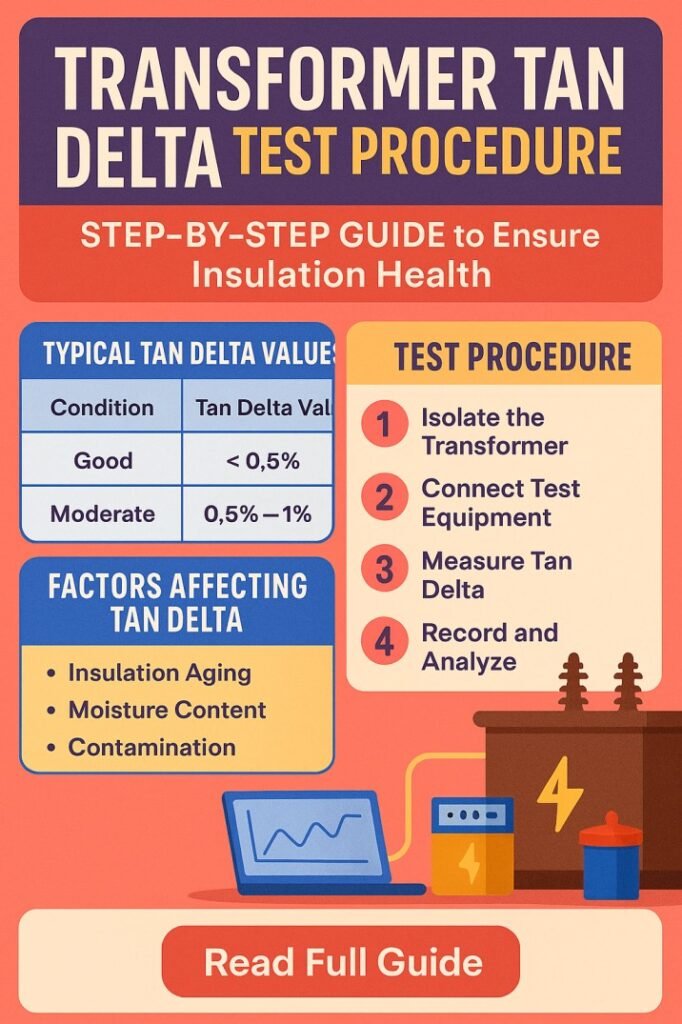

The transformer tan delta test procedure measures the dielectric losses in the insulation system of a transformer. Tan delta, also known as the loss angle, is the ratio of resistive current to capacitive current in the insulation. Essentially, it indicates how much energy is lost as heat when the transformer is energized at a test voltage. A high tan delta value signifies that the insulation is degrading, while a low and stable value indicates healthy insulation.

This test is widely used during commissioning, routine maintenance, and after severe electrical events like lightning strikes or short circuits. Regular testing ensures that transformers operate efficiently and safely without unexpected outages.

Explore all about Top 15 High Voltage Testing Services Indiana – Trusted Experts for Reliable Power Systems

Importance of Performing the Tan Delta Test

Conducting a transformer tan delta test procedure provides several critical benefits:

- Detects insulation deterioration due to moisture, aging, or contamination.

- Helps prevent catastrophic transformer failures.

- Assists in predictive maintenance by monitoring insulation trends over time.

- Confirms the quality of newly installed transformers during commissioning.

- Supports compliance with international standards and best practices.

By identifying potential issues early, utilities and industrial operators can schedule maintenance proactively, reducing downtime and repair costs.

Equipment Required for Tan Delta Testing

Before starting the transformer tan delta test procedure, gather the following equipment:

| Equipment | Purpose |

|---|---|

| High-voltage AC test set | To apply controlled test voltage to transformer windings |

| Measuring instrument with tan delta function | To measure insulation losses accurately |

| Cables and connections | To safely connect the test device to transformer terminals |

| Earthing and safety devices | To ensure operator safety during the test |

| Data logging system | To record and analyze results |

Proper calibration and verification of instruments are essential to ensure the accuracy of the test.

Find all about Partial Discharge vs Tan Delta Cable Testing: Important Key Differences Every Engineer Must Know

Safety Precautions Before Testing

Safety is paramount when performing a transformer tan delta test procedure. High voltages are involved, and improper handling can result in severe injury. Key precautions include:

- Ensure the transformer is completely de-energized.

- Ground all connections and verify the test area is safe.

- Use appropriate personal protective equipment (PPE), including gloves, safety glasses, and insulated mats.

- Isolate the transformer from other equipment and circuits.

- Follow manufacturer guidelines and standard operating procedures strictly.

Adhering to these precautions minimizes risks and ensures accurate test results.

Step-by-Step Transformer Tan Delta Test Procedure

The transformer tan delta test procedure can be divided into systematic steps for clarity and effectiveness.

Step 1: Preliminary Inspection

Start by inspecting the transformer physically. Look for signs of oil leaks, corrosion, or damaged bushings. This visual inspection helps identify any immediate issues that could affect the test results.

Step 2: Connect the Test Equipment

Carefully connect the high-voltage AC test set to the transformer winding terminals. Ensure proper polarity and secure connections. Use shielded cables to minimize interference and maintain safety.

Explore details on High Voltage Cable Testing Procedure: Step-by-Step Guide for Safe & Accurate HV Cable Testing

Step 3: Apply the Test Voltage

Gradually increase the AC test voltage to the rated test level. Do not exceed the maximum recommended voltage. Apply the voltage in steps to prevent sudden stress on the insulation. Observe the current and tan delta readings continuously.

Step 4: Measure Tan Delta Values

Record the tan delta and capacitance values for each winding. For transformers with multiple windings, measure phase-to-phase and phase-to-ground values. Typical acceptable tan delta values vary depending on transformer type, age, and manufacturer specifications.

| Transformer Winding | Test Voltage (kV) | Capacitance (nF) | Tan Delta (°) | Remarks |

|---|---|---|---|---|

| HV Winding | 10 | 500 | 0.5 | Healthy |

| LV Winding | 5 | 1200 | 0.7 | Slightly high |

| Tertiary Winding | 2 | 300 | 0.4 | Normal |

Monitoring these readings allows engineers to detect abnormal insulation behavior and moisture content.

Explore all about vlf testing procedure

Step 5: Compare with Baseline

Compare the measured values with previous records or baseline values provided by the manufacturer. An increasing trend in tan delta over time indicates insulation deterioration and may require maintenance or further investigation.

Step 6: Analyze Phase Differences

Analyze the differences between phases. Significant variation in tan delta readings between phases may indicate localized insulation problems, such as contamination or partial discharge activity. A uniform distribution generally confirms healthy insulation.

Step 7: Complete the Test and Disconnect

After completing the measurements, gradually reduce the test voltage to zero. Disconnect the test equipment carefully, ensuring all safety protocols are followed. Ground all terminals before leaving the site.

Find all about High Voltage Cable Testing Standards: Complete Guide for Engineers

Factors Affecting Tan Delta Readings

Several factors can influence the results of the transformer tan delta test procedure:

- Moisture Content: Higher moisture in insulation increases tan delta values.

- Temperature: Insulation losses vary with temperature; testing should consider temperature corrections.

- Aging: Older transformers may show naturally higher tan delta readings.

- Contaminants: Dust, oil degradation, and chemical residues can affect readings.

- Test Frequency: Standard test frequencies are typically 50 Hz or 60 Hz; deviations can alter results.

Understanding these factors helps engineers interpret results more accurately and make informed maintenance decisions.

Advantages of the Tan Delta Test

The transformer tan delta test procedure offers several advantages over other insulation testing methods:

- Non-destructive and safe for in-service transformers.

- Provides quantitative assessment of insulation condition.

- Detects early signs of deterioration, reducing unexpected failures.

- Supports trend analysis for predictive maintenance programs.

- Can be performed on both oil-filled and dry-type transformers.

Know more about VLF Testing vs Hipot: Best Guide on Key Differences and Applications

Limitations and Considerations

While the tan delta test is highly effective, engineers should be aware of certain limitations:

- It does not pinpoint exact defect locations; further tests like partial discharge analysis may be required.

- Environmental factors such as temperature and humidity can influence results.

- Interpretation requires experience and comparison with historical data.

- Not a standalone test for completely assessing insulation health; it should be combined with other diagnostic methods.

Maintenance Based on Test Results

After completing the transformer tan delta test procedure, engineers can take appropriate maintenance actions based on the readings:

| Tan Delta Value | Condition | Recommended Action |

|---|---|---|

| 0.1 – 0.5 | Normal | Continue routine monitoring |

| 0.5 – 1.0 | Slightly high | Inspect for moisture and oil quality |

| 1.0 – 2.0 | High | Schedule maintenance, check for contamination |

| >2.0 | Critical | Immediate repair or replacement |

Regular monitoring ensures transformers remain reliable and safe while extending service life.

Know more about High Voltage Testing Procedures for Electrical Panels: Step by Step

Conclusion

The transformer tan delta test procedure is a vital diagnostic tool for evaluating the insulation condition of transformers. By following a systematic, step-by-step approach, engineers can accurately detect early signs of deterioration, moisture intrusion, or contamination. Combining tan delta measurements with proper maintenance planning ensures transformer reliability, reduces downtime, and enhances the safety of power systems. Regular implementation of this test, along with careful record-keeping and trend analysis, allows utilities and industrial operators to make informed decisions, maintain optimal performance, and prevent unexpected failures.

By adhering to this comprehensive guide, professionals can confidently perform the transformer tan delta test procedure, ensuring insulation health and extending transformer life for years to come.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TransformerTanDeltaTest, #TanDeltaTesting, #TransformerMaintenance, #ElectricalTesting, #PowerTransformer, #InsulationTesting, #HighVoltageTesting, #TransformerHealth, #ElectricalEngineering, #TanDeltaProcedure