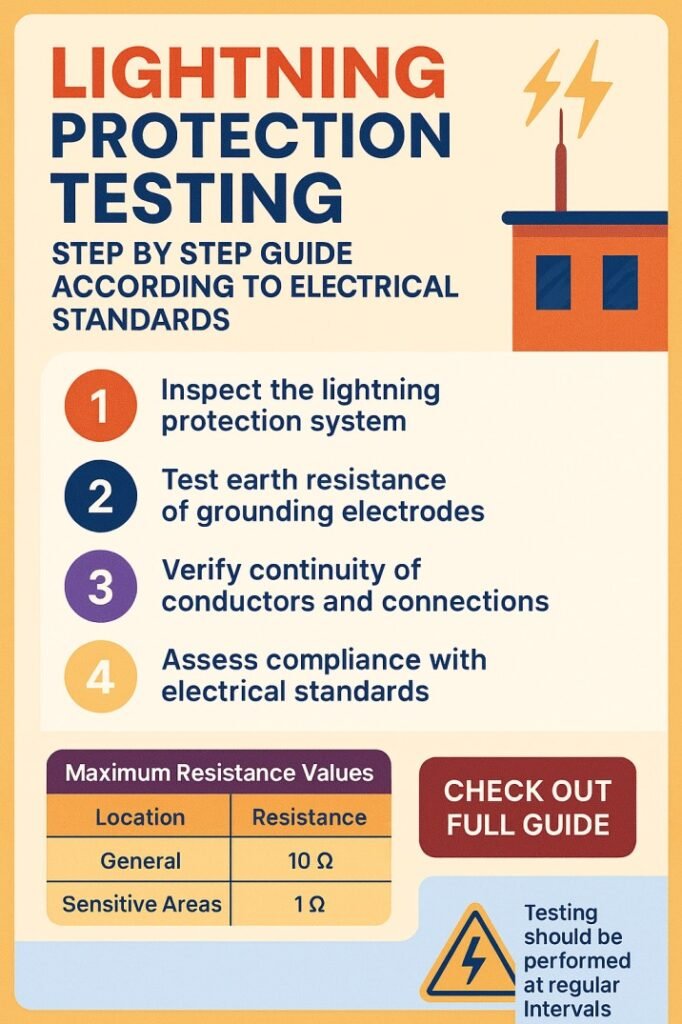

Lightning Protection Testing: Step by Step Guide According to Electrical Standards

Lightning strikes are one of the most dangerous natural phenomena that can cause severe damage to buildings, electrical systems, and sensitive equipment. Ensuring the safety of structures against lightning involves not only installing a proper lightning protection system but also conducting thorough lightning protection testing. Regular testing guarantees that the system functions correctly during an actual lightning event and complies with international electrical standards.

Table of Contents

This guide provides a step-by-step approach to lightning protection testing, helping professionals, engineers, and technicians maintain effective protection.

Understanding Lightning Protection Systems

A lightning protection system is designed to intercept, conduct, and safely dissipate lightning currents into the ground. It typically includes air terminals (lightning rods), conductors, bonding to structural elements, and ground electrodes. The system is classified into external and internal protection: external for shielding the structure and internal for safeguarding electrical equipment from surges caused by lightning. Testing these systems ensures that all components are installed correctly, remain in good condition, and comply with standards such as IEC 62305 or NFPA 780.

Importance of Lightning Protection Testing

Regular lightning protection testing is critical for several reasons. First, it identifies any degradation in the system due to corrosion, physical damage, or improper installation. Second, it ensures compliance with electrical safety regulations, which is mandatory in many regions. Finally, it provides confidence that the structure is safeguarded against potential lightning strikes, reducing risks of fire, structural damage, and equipment failure.

Know more about What Is Early Streamer Emission A Practical Guide for Engineers, Standards, and Lightning Protection Design

Tools and Equipment Required for Testing

Before performing lightning protection testing, it is essential to gather the proper tools and equipment. The following list includes commonly used devices:

| Equipment | Purpose |

|---|---|

| Insulation Resistance Tester (Megger) | Measures insulation resistance of conductors and connections |

| Continuity Tester | Checks the integrity of conductors and bonding |

| Earth Resistance Tester | Determines the effectiveness of grounding electrodes |

| Clamp Meter | Measures current carrying capacity in conductors |

| Visual Inspection Tools | Detects physical damage, corrosion, and loose connections |

| Surge Protection Test Device | Verifies the performance of surge protective devices (SPDs) |

Using these tools allows professionals to perform comprehensive testing, ensuring that each component of the lightning protection system functions optimally.

Know more about What Is Air Terminal in Lightning Protection? Function, Types & Installation Explained

Step 1: Visual Inspection

The first step in lightning protection testing is a detailed visual inspection. Inspect all external and internal components, including:

- Lightning rods and air terminals for corrosion, loosened mounts, or bent tips.

- Conductors for physical damage or improper routing.

- Grounding electrodes for corrosion or detachment.

- Bonding connections to structural elements.

Documenting all observations ensures that any issues are addressed before proceeding to electrical testing. Proper visual inspection prevents false readings and ensures the reliability of subsequent tests.

Step 2: Continuity Testing

Continuity testing verifies that all conductors in the lightning protection system are properly connected. Using a continuity tester, check the connection from the air terminals to the ground electrodes. Every joint, clamp, and bonding point must demonstrate low resistance, typically less than 1 ohm, as per IEC 62305 guidelines. Poor continuity can cause lightning currents to take unintended paths, risking structural damage and equipment failure.

Know more about Earth Cable Size for Lightning Protection

Step 3: Insulation Resistance Testing

Insulation resistance testing ensures that conductors are isolated from non-conductive surfaces and structural materials. This test is performed using a megger or insulation resistance tester. A high resistance value indicates proper insulation, while low resistance suggests a risk of current leakage, which can be hazardous during a lightning strike. Generally, insulation resistance should be above 1 MΩ for reliable operation.

Step 4: Ground Resistance Measurement

Effective grounding is crucial for a lightning protection system. The ground resistance of electrodes must be measured to ensure safe dissipation of lightning currents. The standard method uses an earth resistance tester or a three-point fall-of-potential test. According to IEC 62305, the acceptable ground resistance should typically be below 10 ohms for general structures, but critical facilities often require 2–5 ohms for enhanced protection. Maintaining low resistance ensures the system can safely carry high currents without causing damage.

| Ground Resistance | Recommended Value |

|---|---|

| Residential Buildings | <10 Ω |

| Commercial/Industrial | 5–10 Ω |

| Critical Infrastructure | 2–5 Ω |

Know more about Leakage Current in Lightning Arrester: Best Guide

Step 5: Surge Protection Device Testing

Lightning strikes often induce high-voltage surges that can damage sensitive equipment. Surge Protective Devices (SPDs) are installed in electrical panels to mitigate this risk. Testing SPDs involves applying controlled voltage surges to confirm that they operate within specified limits. Malfunctioning SPDs should be replaced immediately, as they are the last line of defense for internal electrical systems.

Step 6: Bonding and Equipotential Testing

Equipotential bonding ensures that all conductive parts of a structure, including metallic roofs, water pipes, and electrical systems, are at the same potential. Testing involves measuring resistance between bonded parts to ensure they are below 1 ohm. Proper bonding reduces the risk of dangerous step and touch voltages during a lightning strike.

Step 7: Documentation and Compliance

After completing all tests, documenting the results is essential. This includes:

- Test methods and standards followed

- Measured values of continuity, insulation, ground resistance, and bonding

- Observations and corrective actions taken

Proper documentation is not only a regulatory requirement but also provides a reference for future inspections and maintenance schedules. It confirms compliance with standards such as IEC 62305, NFPA 780, and local electrical regulations.

Know more about IEC Standard for Lightning Protection: A Complete Technical Guide

Step 8: Maintenance and Periodic Testing

Lightning protection testing is not a one-time activity. Systems should undergo periodic inspections and testing, typically every 1–3 years depending on environmental conditions and building type. Regular maintenance includes cleaning air terminals, tightening connections, replacing corroded parts, and verifying grounding effectiveness. Routine testing ensures long-term reliability and safety.

| Testing Interval | Recommended Action |

|---|---|

| Every 12 months | Visual inspection and continuity test |

| Every 2–3 years | Full system testing including insulation and ground resistance |

| After Severe Storms | Immediate inspection for damage or deterioration |

Common Challenges in Lightning Protection Testing

Despite following proper procedures, professionals may encounter certain challenges:

- Corroded conductors or clamps: Can increase resistance and reduce protection efficiency.

- Complex grounding networks: Multiple electrodes may require specialized testing methods.

- Access difficulties: Tall structures or difficult-to-reach areas can complicate inspections and measurements.

- Environmental factors: Moisture, soil resistivity, and temperature can affect test results and system performance.

Addressing these challenges requires trained personnel, proper equipment, and adherence to electrical standards.

Know more about IEC Standard for Lightning Arrester – IEC 60099 Guide for Surge and Overvoltage Protection

Conclusion

Lightning protection testing is an essential practice to ensure the safety and effectiveness of a lightning protection system. Following a structured step-by-step approach—including visual inspection, continuity testing, insulation resistance measurement, ground resistance verification, SPD testing, and bonding checks—guarantees compliance with electrical standards and reduces risks associated with lightning strikes. Regular testing, proper documentation, and timely maintenance are the keys to reliable protection.

By implementing these procedures, engineers and technicians can confidently safeguard structures, equipment, and human life against one of nature’s most powerful forces.

Know more about Top 10 Lightning Protection Design Softwares: Best Guide

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#LightningProtectionTesting, #SurgeProtection, #ElectricalSafety, #LightningSafety, #BuildingProtection, #GroundingSystems, #ElectricalInspection, #LightningRiskAssessment, #ProtectYourBuilding, #SafetyStandards