Cable Size Calculation Thumb Rule – Fast, Practical Method Engineers Use for Accurate Wire Sizing

Electrical professionals often need a quick answer on site. Drawings may not be available, and software tools are not always practical during installation or inspection. In such situations, the cable size calculation thumb rule becomes a reliable method for selecting a safe and practical conductor size without long calculations.

Table of Contents

The cable size calculation thumb rule is widely used by field engineers, maintenance teams, and electrical supervisors. It offers a fast estimate that is close enough to detailed design values when applied correctly. While it does not replace full load calculations, it helps prevent undersized cables, overheating, and excessive voltage drop.

Understanding how this cable size calculation thumb rule works can save time, reduce installation errors, and improve overall electrical safety.

Why Engineers Use Thumb Rules for Cable Sizing

In real projects, decisions are often made under time pressure. Motors trip, panels overheat, or temporary supplies are needed. Engineers cannot always open design manuals or run detailed simulations.

That is where the cable size calculation thumb rule becomes useful. It provides a quick relationship between current and conductor cross-sectional area. This helps in choosing a cable that can safely carry load current without exceeding temperature limits.

Thumb rules are based on practical experience, standard installation methods, and typical insulation ratings. When used with engineering judgment, they offer dependable results for most low-voltage systems.

Try this tool out to save time and effort for easy conversions Amps to Wire Size Calculator – Choose the Right Cable for 10A, 20A, 40A Loads

Basic Concept Behind the Thumb Rule

Every cable has a current carrying capacity, also called ampacity. This depends on conductor material, insulation type, installation method, and ambient temperature. The cable size calculation thumb rule simplifies these variables into easy numbers that engineers can remember.

For copper conductors in low-voltage systems, a common field assumption is:

1 sq.mm copper ≈ 4 to 6 amperes (depending on installation)

This range allows engineers to quickly estimate cable size without detailed tables.

For aluminium conductors, the current capacity is lower because aluminium has higher resistance. A practical approximation used in the cable size calculation thumb rule is:

1 sq.mm aluminium ≈ 3 to 4 amperes

These values are not exact design limits, but they are very useful for first-level sizing.

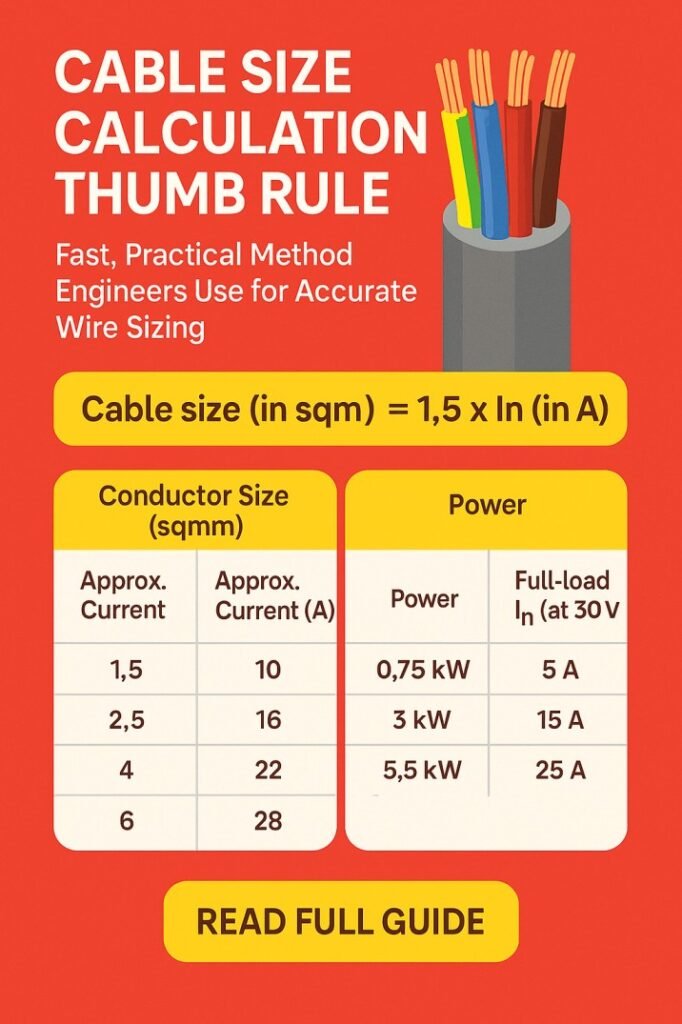

Quick Reference Table for Copper Cables

Below is a practical table many engineers rely on when applying the cable size calculation thumb rule in buildings and industrial plants.

| Load Current (A) | Approx Copper Cable Size (sq.mm) | Typical Application |

|---|---|---|

| 10 A | 1.5 sq.mm | Lighting circuits |

| 16 A | 2.5 sq.mm | Socket outlets |

| 25 A | 4 sq.mm | Small appliances |

| 32 A | 6 sq.mm | AC units |

| 40 A | 10 sq.mm | Sub-distribution |

| 63 A | 16 sq.mm | Small feeders |

| 80 A | 25 sq.mm | Distribution board |

| 100 A | 35 sq.mm | Main feeder |

This table is derived from the cable size calculation thumb rule and assumes standard PVC insulated copper cables installed in conduit or cable trays under normal temperature.

We recommend this tool for anyone struggling with the sizing of subpanels. Try here Wire Size Calculator for Subpanels and Feeders – NEC Guidelines Included

Thumb Rule Formula Engineers Remember

Many engineers prefer a simple formula instead of memorizing tables. A widely used version of the cable size calculation thumb rule for copper is:

Cable size (sq.mm) ≈ Load current (A) ÷ 5

This assumes a mid-range value of 5 A per sq.mm. For example, if the load current is 50 A:

50 ÷ 5 = 10 sq.mm cable

This result matches closely with standard ampacity charts for common installation methods. The cable size calculation thumb rule works best for low-voltage distribution, motor feeders, and building wiring.

For aluminium conductors, engineers often modify the rule:

Cable size (sq.mm) ≈ Load current (A) ÷ 3

Because aluminium carries less current per unit area, this adjustment improves accuracy.

Considering Voltage Drop with Thumb Rules

Current capacity is not the only factor. Voltage drop is also important, especially for long cable runs. A cable may carry the current safely but still cause low voltage at the load end.

A practical extension of the cable size calculation thumb rule is to increase the cable size by one standard step if the cable length exceeds 30 meters for power circuits. For motor loads, engineers are even more careful because starting current can cause higher voltage drop.

Take a look at this tool for a smarter way to handle feeder wire sizing Feeder Wire Size Calculator – Accurate Guide for Electricians and Homeowners

Here is a simple field guide:

| Cable Length | Thumb Rule Adjustment |

|---|---|

| Up to 30 m | Use calculated size |

| 30–60 m | Go one size higher |

| Above 60 m | Check voltage drop properly |

This approach keeps the cable size calculation thumb rule safe for longer distances without complex formulas.

Motor Load Thumb Rule

Motors draw high starting current. That is why cable sizing for motors must be slightly conservative. A common practice linked with the cable size calculation thumb rule is to size the cable at 125% of full load current.

Example:

Motor full load current = 32 A

Design current = 32 × 1.25 = 40 A

Using the thumb rule:

40 ÷ 5 = 8 sq.mm → Select next standard size 10 sq.mm

This method ensures the cable can handle starting conditions and continuous operation.

This tool can help you get the job done more efficiently Solar Wire Size Calculator (DC): Best Solar Cable Sizing Tool

Ambient Temperature and Grouping Effect

The cable size calculation thumb rule assumes normal ambient temperature around 30°C and single cable installation. In real sites, cables may be grouped in trays or installed in hot environments.

In such cases, heat cannot dissipate easily. Engineers then increase the cable size by one step as a safety margin. For example, if the thumb rule suggests 16 sq.mm, they may choose 25 sq.mm when multiple cables run together.

This adjustment keeps conductor temperature within insulation limits and avoids premature insulation failure.

When Thumb Rules Should Not Be Used Alone

Although the cable size calculation thumb rule is very practical, it is not meant for final design of critical systems. Large industrial feeders, long underground runs, and high fault level systems require detailed calculations.

Protection coordination, short circuit rating, and derating factors must be checked using standards and manufacturer data. The thumb rule is best used for quick estimation, troubleshooting, and preliminary sizing.

Engineers often start with the cable size calculation thumb rule and then verify with proper ampacity charts and voltage drop calculations before final approval.

Explore this tool here to simplify your work instantly Neutral Conductor Sizing Calculator – Accurate Neutral Wire Size for Electrical Circuits

Common Mistakes to Avoid

Some mistakes reduce the accuracy of the cable size calculation thumb rule. One common error is ignoring aluminium and copper differences. Using the same factor for both can lead to undersized aluminium cables.

Another mistake is forgetting future load expansion. If a feeder may carry more load later, engineers usually select the next larger size. This small step prevents costly cable replacement.

Ignoring installation method is also risky. Cables buried underground or installed in insulation need different derating compared to open air installation.

Practical Summary Table

| Situation | Thumb Rule Action |

|---|---|

| Normal building wiring | Current ÷ 5 for copper |

| Aluminium conductor | Current ÷ 3 |

| Long cable run | Increase one size |

| Motor feeder | Use 125% of FLC first |

| High temperature area | Increase one size |

These simple steps make the cable size calculation thumb rule a powerful tool for daily electrical work.

You might find this tool useful for tackling similar tasks Sub Panel Wire Size Calculator – Accurate Wire Gauge & Load Sizing Tool

Final Thoughts

The cable size calculation thumb rule is not just a shortcut. It is a field-tested method built on years of engineering practice. When applied with awareness of voltage drop, temperature, and installation conditions, it provides safe and efficient cable selection.

Engineers who master this cable size calculation thumb rule can make quick, confident decisions during installation and maintenance. It reduces guesswork, improves safety, and ensures electrical systems perform reliably under real operating conditions.

Check out this tool that makes the process much easier and faster MM to AWG Wire Size Calculator According to IEC and NEC

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#CableSizeCalculation #ElectricalDesign #WireSizing #ElectricalEngineering #PowerDistribution #VoltageDrop #CableSelection #MEPDesign #ElectricalStandards #EngineeringBasics