Motor Service Factor With VFD: NEC Guidance, Proper Sizing Methods, and Professional Application Standards

Understanding Motor Service Factor in Modern Drive Systems

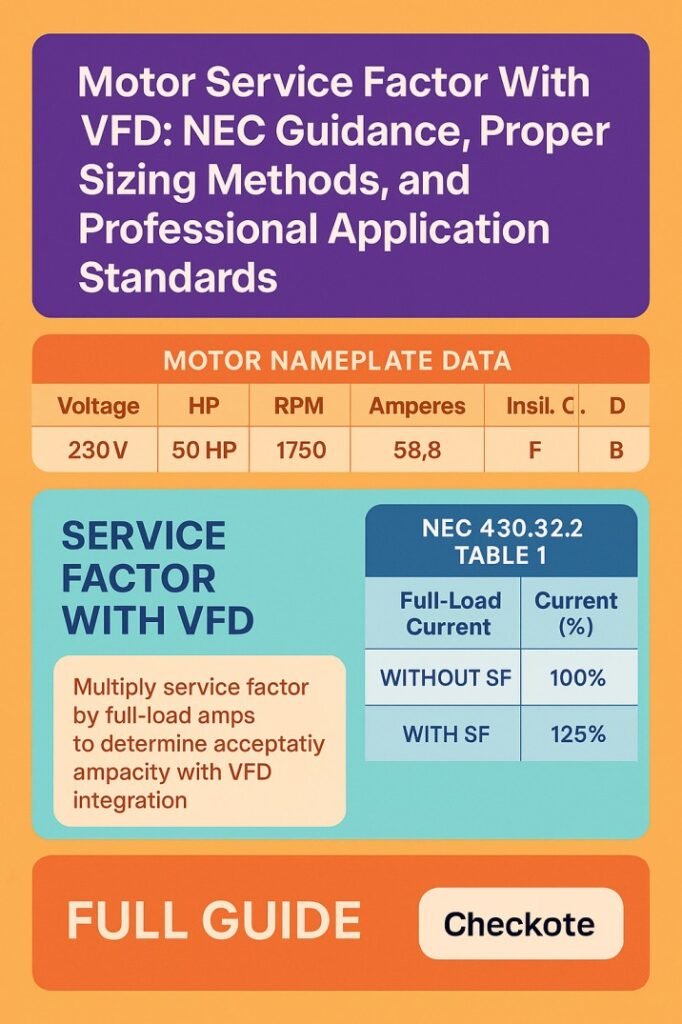

Motor service factor with VFD is a topic that often creates confusion in industrial and commercial installations. A motor service factor traditionally allows a motor to operate above its rated horsepower for short periods under specific conditions. Standard NEMA motors often have a service factor of 1.15, meaning a 10 HP motor could handle 11.5 HP under ideal voltage and temperature limits. However, when a variable frequency drive is involved, electrical and thermal stresses change significantly.

Table of Contents

A VFD modifies the power waveform supplied to the motor. Instead of smooth sinusoidal power, the motor receives pulse width modulated voltage. This introduces additional heating, insulation stress, and harmonic content. Because of these factors, the usable motor service factor with VFD operation is usually reduced compared to across-the-line starting. Ignoring this detail is a common cause of premature motor failure.

NEC and Industry Guidance

The National Electrical Code does not directly redefine motor service factor with VFD, but it provides rules that affect conductor sizing, overload protection, and motor protection. NEC Article 430 remains the foundation for motor installations, while Article 100 and 430.122 address adjustable-speed drive systems.

Know more about Coincidence Factor vs Diversity Factor: The Load Calculation Mistake Engineers Still Make

Key NEC-related considerations include:

- Conductors feeding a VFD must be sized based on the drive’s input current rating, not just motor nameplate current

- Overload protection is typically provided electronically inside the VFD rather than by traditional thermal overload relays

- Motor overtemperature protection becomes more critical because VFD operation can reduce cooling at low speeds

Most drive manufacturers clearly state that the full nameplate service factor should not be assumed when operating on a VFD unless the motor is specifically rated for inverter duty. This is where motor service factor with VFD becomes a design decision rather than a simple nameplate value.

Why Service Factor Changes With a VFD

At low speeds, a motor’s shaft-mounted fan moves less air. Cooling drops while current may remain high, especially in constant torque loads like conveyors or compressors. This leads to higher winding temperatures even when the motor is not overloaded in the traditional sense.

Additional heating sources include:

- Harmonic currents caused by PWM switching

- Higher dv/dt stressing motor insulation

- Circulating bearing currents in some installations

Because temperature rise is the main limiter of service factor usage, motor service factor with VFD must be treated conservatively unless the motor has Class F or H insulation and is labeled inverter duty.

Know more about Difference Between Relay and Contactor: 7 Powerful Reasons This Guide Makes It Easy

Proper Motor and Drive Sizing Methods

Correct sizing ensures reliability and compliance. The process should consider load type, duty cycle, ambient temperature, and enclosure.

| Parameter | Across-the-Line Motor | Motor on VFD |

|---|---|---|

| Cooling effectiveness | Full at rated speed | Reduced at low speed |

| Usable service factor | Often 1.15 | Often limited to 1.0 |

| Heating from harmonics | Minimal | Moderate to high |

| Overload handling | Thermal overload relay | Electronic model in VFD |

When evaluating motor service factor with VFD, professionals often follow these steps:

- Select an inverter-duty motor whenever continuous low-speed operation is expected

- Size the motor so normal load does not exceed 100% of nameplate amps at required speed

- Avoid relying on service factor for continuous operation under VFD control

- Verify that the VFD current rating exceeds the motor full load current at the required overload level

This approach reduces thermal stress and extends insulation life.

Know more about Power Factor vs Crest Factor: Important Differences & Comparison

Professional Application Standards

Industry best practice treats motor service factor with VFD as an emergency or short-duration margin, not a routine operating condition. IEEE, NEMA MG-1 Part 31, and major drive manufacturers all recommend conservative loading when motors are powered by adjustable frequency drives.

Professional installations often include:

- Shaft grounding rings to reduce bearing damage

- Output reactors or dv/dt filters for long cable runs

- Separate motor cooling blowers in constant torque, low-speed applications

These measures address the extra electrical stress introduced by VFD systems and protect the motor beyond what service factor alone can handle.

Field Example and Practical Limits

Consider a 15 HP pump motor with a 1.15 service factor. Across the line, occasional loading up to 17.25 HP may be acceptable if voltage and temperature stay within limits. Under VFD control, especially at reduced speeds, the safe continuous limit is usually kept at or below 15 HP. In this case, motor service factor with VFD is reserved only for brief overloads during transients such as startup or process spikes.

Know more about What is Demand Factor and Diversity Factor? Quick Concepts

Ignoring this derating often leads to nuisance trips, overheated windings, or shortened insulation life. Maintenance data from industrial plants consistently shows higher failure rates when motors are run into their service factor under drive control.

Final Design Recommendations

For reliable installations, motor service factor with VFD should never be assumed equal to across-the-line capability. Instead, designers should prioritize thermal margin, inverter-duty construction, and correct drive sizing.

Best practice summary:

- Treat service factor as temporary capacity, not continuous rating

- Use inverter-duty motors for VFD applications

- Confirm NEC-compliant conductor and protection sizing

- Add thermal and bearing protection where needed

Following these professional standards ensures longer motor life, fewer shutdowns, and safer electrical systems in modern variable speed applications.

Know more about Coincidence Factor vs Demand Factor

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#MotorServiceFactor, #VFDApplications, #ElectricMotorSizing, #NECCompliance, #IndustrialDrives, #MotorEngineering, #ElectricalStandards, #DriveSystemDesign, #MotorProtection, #PowerSystemDesign