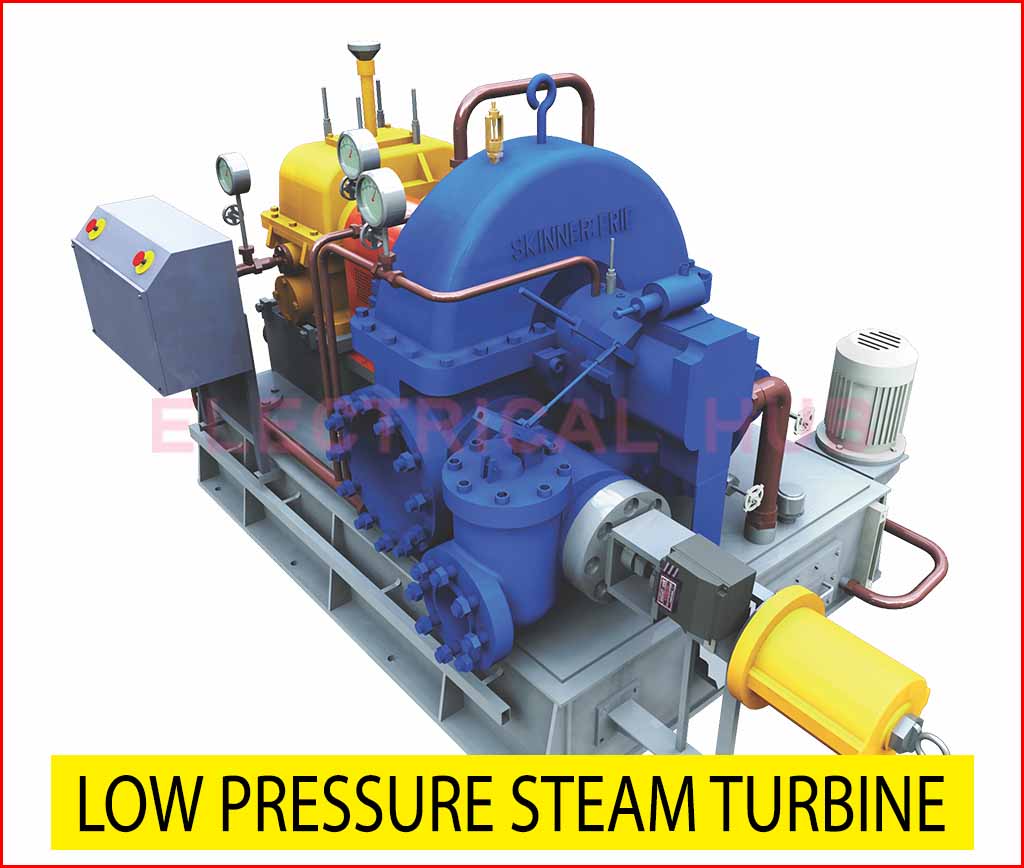

Low Pressure Steam Turbine: The Key to Efficient Power Generation

Low pressure steam turbines play a crucial role in modern power generation systems. They are vital for converting steam energy into mechanical energy to drive electrical generators. These turbines are used across various industries, from power plants to manufacturing facilities.

This article will explore the working principles, components, and advantages of low pressure steam turbines. We’ll also discuss related topics like impulse turbines, reaction turbines, combustion turbine generators, and steam turbine power plants.

Table of Contents

Table of Contents

What Is a Low Pressure Steam Turbine?

A low pressure steam turbine is a type of steam turbine designed to operate using steam at relatively low pressure. These turbines are typically placed in the later stages of a steam power plant cycle, where high-pressure steam has already undergone partial energy extraction. Low pressure turbines play a significant role in improving the efficiency of steam power plants by utilizing leftover energy in the steam.

How Does a Low Pressure Steam Turbine Work?

The working of a low pressure steam turbine can be summarized in a series of steps:

Steam Entry: Steam enters the turbine at low pressure, typically after passing through a high-pressure or intermediate-pressure turbine.

Energy Conversion: The steam flows over the turbine blades, converting thermal energy into mechanical energy. This process involves either impulse action, reaction action, or a combination of both, depending on the turbine type.

Power Generation: The mechanical energy generated by the turbine is transferred to a generator, producing electricity.

Exhaust: The remaining low-energy steam is either released into a condenser for recycling or directly into the atmosphere, depending on the system design.

This seamless conversion process ensures that no energy from the steam goes to waste, maximizing efficiency.

Key Components of a Low Pressure Steam Turbine

A low pressure steam turbine consists of several components that work together to convert steam into mechanical energy effectively.

1. Rotor and Blades

The rotor is a rotating shaft fitted with blades. These blades are designed to maximize the transfer of energy from steam to the turbine. Depending on the steam turbine type, the blades may function based on impulse or reaction principles.

2. Casing

The casing houses the turbine components and ensures that steam flows correctly over the blades. It also helps maintain the required pressure conditions within the turbine.

3. Bearings

Bearings support the rotor and allow it to spin freely while minimizing friction.

4. Nozzles

Nozzles direct the flow of steam onto the turbine blades. For impulse turbines, nozzles are essential in controlling the velocity and pressure of the steam.

5. Condenser

The condenser is used to cool and condense the exhaust steam into water, enabling its reuse in the power cycle.

Advantages of Low Pressure Steam Turbines

Low pressure steam turbines offer several advantages, making them a popular choice in power generation systems.

1. Enhanced Efficiency

By extracting energy from low pressure steam, these turbines ensure minimal energy wastage. They are often used alongside high-pressure and intermediate-pressure turbines to achieve maximum efficiency.

2. Cost-Effective

Installing a low pressure steam turbine in a steam turbine power plant can reduce operational costs by utilizing energy that would otherwise be wasted.

3. Environmentally Friendly

These turbines help reduce greenhouse gas emissions by making steam power plants more energy-efficient.

4. Versatile Applications

Low-pressure steam turbines are compatible with various industrial processes, including those involving combustion turbine generators and cogeneration systems.

5. Durability and Reliability

Modern low-pressure turbines are designed for long operational life and consistent performance, ensuring reliable power generation.

Applications of Low Pressure Steam Turbines

Low-pressure steam turbines find applications in:

Power Plants: They are a crucial component in steam turbine power plants, where they extract energy from steam after it has passed through high-pressure stages.

Industrial Processes: They are used in industries where steam is a byproduct, such as chemical plants and refineries.

Cogeneration Systems: These turbines are part of systems that produce both electricity and heat, improving overall efficiency.

Low Pressure Steam Turbine vs. Other Turbine Types

When comparing low-pressure turbines to other steam turbine types, there are a few key differences:

Operating Pressure: Low-pressure turbines work at lower steam pressures compared to high-pressure or intermediate-pressure turbines.

Efficiency Contribution: They focus on extracting the remaining energy from steam, complementing the earlier stages of a power cycle.

Design: The blade design in low-pressure turbines is optimized for handling large volumes of low-pressure steam.

Impulse turbines and reaction turbines are commonly used in low-pressure applications, with each type having unique design features. Impulse turbines rely on high-speed steam jets, while reaction turbines utilize the pressure drop across the blades for energy transfer.

Steam Turbine Power Plant: The Bigger Picture

In a steam turbine power plant, low-pressure turbines are typically the last stage of the energy conversion process. High-pressure and intermediate-pressure turbines handle the initial energy extraction, while low-pressure turbines maximize efficiency by utilizing the remaining steam energy.

This integration ensures that power plants operate at peak performance, reducing energy losses and improving overall output. By combining technologies like low-pressure turbines and combustion turbine generators, power plants can achieve a balance between efficiency and cost-effectiveness.

Future of Low Pressure Steam Turbines

As the demand for efficient and sustainable energy solutions grows, the role of low-pressure steam turbines will become even more critical. Innovations in turbine materials, blade design, and steam management systems are expected to further enhance their performance.

These turbines will continue to be an integral part of steam turbine power plants, helping industries achieve their energy efficiency and sustainability goals.

Final Thoughts

Low-pressure steam turbines are an essential component of modern power generation systems. By utilizing the leftover energy in steam, these turbines enhance efficiency, reduce costs, and contribute to a more sustainable future.

Their versatility and compatibility with various systems, including impulse turbines, reaction turbines, and combustion turbine generators, make them indispensable for industries worldwide. Whether in a steam turbine power plant or an industrial process, the benefits of low-pressure turbines are undeniable.

By understanding the working, components, and advantages of these turbines, we can appreciate their role in shaping the future of energy production.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#LowPressureSteamTurbine, #SteamTurbine, #TurbineTechnology, #EnergyGeneration, #LowPressureTurbine, #SteamPower, #TurbineEfficiency, #PowerGeneration, #EngineeringInnovation, #RenewableEnergy, #MechanicalEngineering, #EnergySolutions, #IndustrialTurbines, #SteamEngineTech, #TurbineDesign