IEC 61508 Standard: A Comprehensive Guide

The IEC 61508 standard is a widely recognized international standard for the functional safety of electrical, electronic, and programmable electronic (E/E/PE) systems. Its importance lies in its ability to help industries design systems that are safe, reliable, and in compliance with modern safety standards. This guide provides a detailed overview of the IEC 61508 standard, its structure, technical details, and why it’s crucial for industries dealing with safety-critical systems.

Table of Contents

Table of Contents

What is the IEC 61508 Standard?

The IEC 61508 standard is a foundational document developed by the International Electrotechnical Commission (IEC). It addresses the functional safety of systems that incorporate E/E/PE components and are used in applications where failures could pose significant risks to human life, property, or the environment.

The standard provides a framework for managing risks by defining safety requirements throughout the lifecycle of a product or system. It serves as the benchmark for industries such as energy, manufacturing, transportation, and more.

Key Features of IEC 61508

Risk Assessment: IEC 61508 emphasizes identifying hazards and assessing risks to determine the necessary safety integrity level (SIL).

Lifecycle Approach: The standard covers all phases of a system’s lifecycle, including design, development, operation, and decommissioning.

Safety Integrity Levels (SILs): It categorizes safety requirements into four SILs (1 to 4), where SIL 4 represents the highest level of safety integrity.

Flexibility: IEC 61508 can be applied across various industries, making it adaptable to different safety-critical environments.

Compliance: Many industries use IEC 61508 to demonstrate compliance with regulatory requirements and to ensure product safety.

Structure of IEC 61508 Standard

The IEC 61508 is divided into seven parts, each addressing a specific aspect of functional safety:

Part 1: General requirements—Provides an overview of the standard and defines key concepts such as SILs and safety lifecycle.

Part 2: Requirements for E/E/PE systems—Focuses on hardware safety.

Part 3: Software requirements—Outlines safety considerations for software in safety-critical systems.

Part 4: Definitions—Offers detailed definitions of terms and concepts used in the standard.

Part 5: Safety integrity levels—Explains how to determine and assign SILs.

Part 6: Guidelines on applying Parts 2 and 3—Practical guidance for implementing hardware and software requirements.

Part 7: Overview and examples—Provides illustrative examples and case studies.

Each of these parts contributes to the comprehensive nature of the standard, ensuring a holistic approach to functional safety.

Importance of Safety Integrity Levels (SILs) in IEC 61508

One of the core elements of IEC 61508 is the concept of Safety Integrity Levels (SILs). SILs quantify the reliability of safety functions and help determine the required performance of a safety system.

SIL Levels and Probability of Failure

| SIL Level | Probability of Failure (Per Hour) | Application Example |

|---|---|---|

| SIL 1 | 10⁻¹ – 10⁻² | Basic process controls |

| SIL 2 | 10⁻² – 10⁻³ | Industrial automation |

| SIL 3 | 10⁻³ – 10⁻⁴ | Transportation systems |

| SIL 4 | 10⁻⁴ – 10⁻⁵ | Nuclear safety mechanisms |

Assigning the correct SIL level is essential for mitigating risks effectively and ensuring system reliability. For example, an en 61508-compliant system in the transportation sector would require a higher SIL compared to a basic industrial process control system.

Benefits of IEC 61508 for Industries

The IEC 61508 standard offers numerous benefits for industries, especially those dealing with safety-critical systems:

Risk Mitigation: By following the standard, organizations can systematically identify and address potential hazards.

Regulatory Compliance: Many regulatory bodies require adherence to IEC safety standards, making IEC 61508 a key document for certification.

Improved Reliability: The standard enhances system reliability by setting stringent safety requirements.

Cost Efficiency: Early identification of safety issues reduces long-term costs associated with system failures.

Global Acceptance: As an international standard, IEC 61508 ensures interoperability and consistency across global markets.

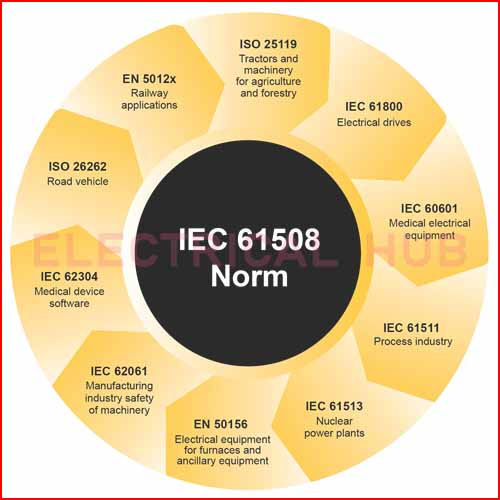

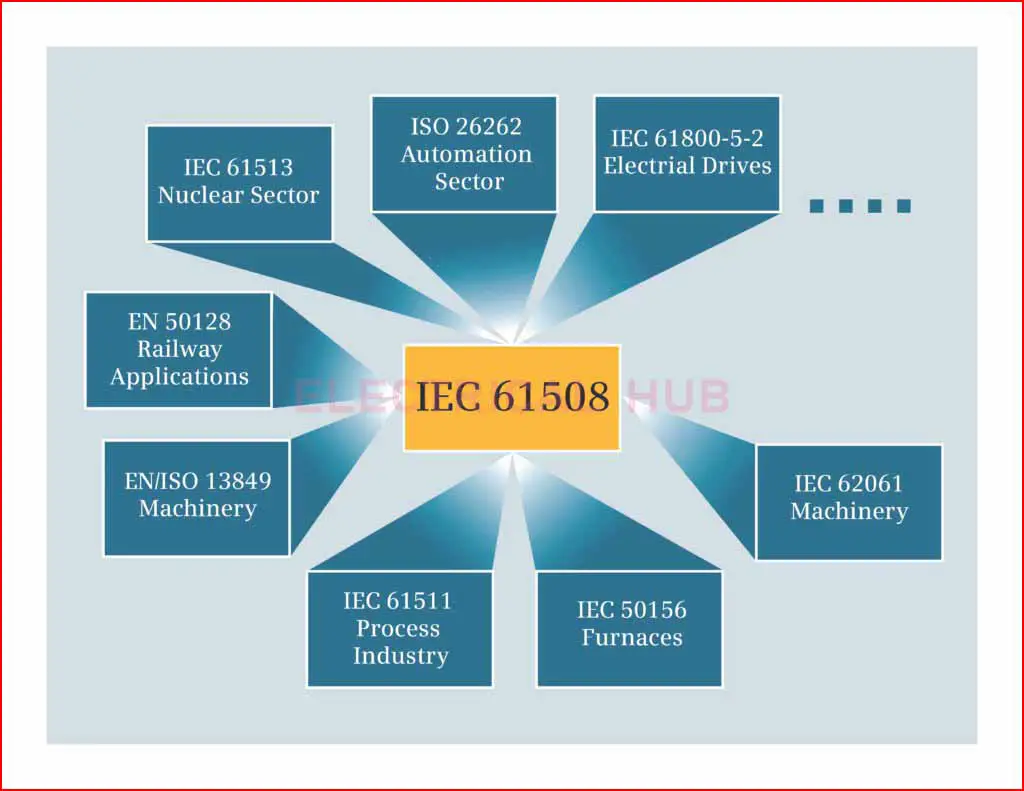

Applications of IEC 61508 Standard

The 61508 IEC standard is used in various industries where functional safety is critical. Some of its primary applications include:

1. Process Industries

The standard is commonly applied in industries such as oil and gas, chemicals, and pharmaceuticals. Here, it ensures the safety of control systems managing hazardous processes.

2. Transportation

From railways to automotive systems, IEC EN 61508 is essential for ensuring the safety of systems such as signaling, braking, and automated driving.

3. Energy and Power

In energy sectors, especially nuclear and renewable energy, iso/iec 61508 compliance ensures the safety of critical systems like turbines, generators, and control panels.

4. Medical Devices

The standard helps ensure that medical devices operate safely, minimizing risks to patients and healthcare professionals.

Challenges in Implementing IEC 61508 Standards

Despite its benefits, implementing the IEC 61508 standards can present certain challenges:

Complexity: Understanding and applying the standard’s requirements across a system’s lifecycle can be complex.

Cost: Achieving compliance often involves significant investment in design, testing, and validation.

Training: Organizations may need to train personnel to understand and implement the standard effectively.

Documentation: Maintaining extensive documentation, as required by the standard, can be time-consuming.

However, overcoming these challenges is worthwhile, given the safety and reliability benefits the standard offers.

How to Get Started with IEC 61508

To implement IEC EN 61508 effectively, follow these steps:

Conduct Risk Assessments: Begin by identifying potential hazards and their associated risks.

Determine SIL Requirements: Use the standard’s guidelines to assign appropriate SIL levels to safety functions.

Develop Safety Plans: Create a comprehensive safety plan covering all lifecycle phases.

Implement Design and Testing: Design and test systems to meet the required SIL levels.

Document Processes: Maintain detailed records to demonstrate compliance.

Continuous Monitoring: Regularly review and update safety measures to ensure ongoing compliance.

By following these steps, organizations can align with the IEC 61508 standard and enhance the safety of their systems.

Related Standards and Resources

The IEC 61508 standard is closely related to several other IEC standards that address specific aspects of safety and reliability. Some of these include:

- IEC 61000 Standards: Focuses on electromagnetic compatibility.

- IEC 60079: Covers equipment used in explosive atmospheres.

- Earthing Cable Size as Per IEC: Provides guidelines for selecting earthing cable sizes.

- IEC 61000-5-2: Details electromagnetic compatibility in installations.

- IEC Standard for Instrument Earthing: Addresses earthing practices for instruments.

- IEC 17025: Defines requirements for testing and calibration laboratories.

- IEC 62443: Focuses on cybersecurity for industrial automation systems.

By exploring these standards, organizations can gain a broader understanding of safety and compliance in their respective fields.

Conclusion

The IEC 61508 standard is an essential tool for industries aiming to ensure the functional safety of their systems. Its comprehensive approach to risk assessment, lifecycle management, and SIL determination makes it a critical resource for safety-critical applications. While implementing the standard may pose challenges, its benefits in terms of safety, reliability, and compliance far outweigh the costs.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IEC61508, #FunctionalSafety, #SafetyStandards, #IndustrialSafety, #IECStandards, #RiskAssessment, #SafetyLifecycle, #SystemReliability, #ComplianceStandards, #ProcessSafety, #SafetyIntegrity, #SafetyManagement, #IndustrialAutomation, #SafetyEngineering, #SafetyCertification

Definitely, what a magnificent blog and illuminating posts, I will bookmark your website.Have an awsome day!