IEC 61000-5-2 Electromagnetic Compatibility(EMC): Best Guide

IEC 61000-5-2

IEC 61000-5-2 is an international standard that provides guidelines for characterizing the immunity of industrial environments against voltage dips, short interruptions, and voltage variations on the electrical supply. This standard is a part of the IEC 61000 series, which addresses electromagnetic compatibility (EMC) issues.

Table of Contents

This Standard ensures that electrical and electronic equipment can operate without disruption in the presence of electromagnetic disturbances. IEC 61000-5-2 specifically focuses on the voltage quality of power supply systems in industrial environments.

Key Components of IEC 61000-5-2

Voltage Variations: IEC 61000-5-2 specifies the magnitude, duration, and frequency of voltage variations that industrial equipment should withstand without operational disruption. These variations include voltage dips, short interruptions, and voltage variations.

Voltage Test Levels: The standard defines various test levels for voltage variations, categorizing them based on their severity. It sets limits for the voltage levels at which equipment should still operate correctly.

Test Procedures: IEC 61000-5-2 outlines the test procedures and conditions for evaluating equipment’s immunity to voltage variations. The tests are conducted in specialized EMC laboratories, following rigorous protocols.

Example of Voltage Dip Immunity Testing

Let’s consider an example of voltage dip immunity testing based on IEC 61000-5-2 for a piece of industrial equipment. In this case, the equipment is rated to operate at a nominal voltage of 400V, and the standard specifies a voltage dip test with the following parameters:

- Test Voltage: 230V

- Test Duration: 10ms

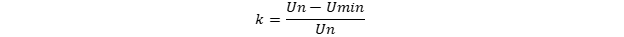

Step 1: Voltage Dip Severity Level Calculation

The first step is to calculate the severity level (k-factor) of the voltage dip. The k-factor is determined using the formula:

Where:

- Un is the nominal voltage (400V).

- Umin is the minimum voltage during the dip (230V).

Calculating k:

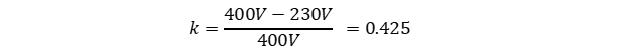

Step 2: Test Voltage Calculation

The test voltage (Udip) during the dip is determined using the formula:

Calculating Udip:

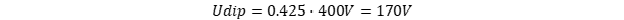

Step 3: Verify Equipment Immunity

The equipment is subjected to a voltage dip test where the voltage is reduced to 170V for a duration of 10ms. If the equipment continues to operate without disruption and remains within its specified performance limits, it complies with the standard’s requirements for voltage dip immunity.

IEC 61000-5-2 provides a comprehensive framework for evaluating and ensuring the robustness of industrial equipment in the face of electrical supply disturbances. Compliance with this standard is crucial for industries where uninterrupted operation is critical, such as manufacturing, process control, and critical infrastructure.

Related Books on IEC 61000-5-2

[wptb id=11110]

Limitations of IEC 61000-5-2

IEC 61000-5-2 is like a guardian for industrial environments, making sure that the electrical supply doesn’t throw equipment off balance. It’s not about “limits” per se; it’s more about setting the rules for how much voltage fluctuation equipment can handle without losing its cool.

The standard categorizes these voltage variations into test levels, kind of like grading the severity of the disturbance. For instance, here are some made-up examples to give you an idea:

- Test Level 1: A voltage dip down to 70% of the nominal voltage for 10 milliseconds.

- Test Level 2: A shorter dip to 40% of the nominal voltage for just 1 millisecond.

- Test Level 3: An even deeper dip to 20% of the nominal voltage, but it’s tolerated for a longer 100 milliseconds.

These test levels depend on the sensitivity of the equipment and the specific application. So, it’s like setting different hurdles for different runners in a race.

The goal of IEC 61000-5-2 is to ensure that industrial equipment keeps chugging along within its specified performance limits, even when the power supply acts a bit wonky. Compliance with these test levels means your equipment won’t get flustered by power supply hiccups.

To get the precise test levels and requirements for your setup, you’d want to check the latest version of the standard or chat with an EMC engineer who can provide guidance tailored to your equipment and the environment it operates.

Follow us on LinkedIn”Electrical Insights” to get the latest updates in Electrical Engineering. You can also Follow us on LinkedIn and Facebook to see our latest posts on Electrical Engineering Topics.

Worth Read Posts

- Methods of Electrical Earthing

- Electrical Earthing Important Types

- Earthing Cable Size as Per IEC

- Plant Factor, Plant Capacity Factor, and Load Factor

- Difference Between Demand Factor and Diversity Factor

- Buck Converter Interview Questions

- DC DC Converter Interview Questions

- Transformer Electrical Interview

- Top 30 Op Amp Interview Questions

- Power Electronics Interview Questions

What is the purpose of IEC 61000-5-2 in simple terms?

Think of it as the rulebook for industrial equipment to stay cool under pressure. It sets the standards for handling voltage fluctuations without breaking a sweat.

Do IEC 61000-5-2 limits vary for different types of equipment?

Absolutely. It’s like tailoring a suit – the standards depend on the sensitivity of the gear. Heavy-duty machinery might have different tolerances than a control panel.

How do I figure out the specific test levels for my equipment?

It’s like getting a custom recipe – consult the latest version of the standard, or chat with an EMC expert who’ll help you tailor it to your gear and environment.

Can you give an example of a voltage dip test level?

Sure, it’s like setting the bar in a high jump. Test Level 1 could be a voltage dip down to 70% of the normal voltage for 10 milliseconds. The higher the level, the tougher the test

Why should I care about IEC 61000-5-2 for my industrial equipment?

Think of it as ensuring your equipment doesn’t panic when things get a little electrically stormy. Compliance keeps your machinery running smoothly even when the power supply isn’t playing nice.

What is IEC 61000-5-2, and why is it important?

IEC 61000-5-2 is part of a series of standards for electromagnetic compatibility. It’s vital for ensuring industrial equipment can operate reliably in the presence of electrical disturbances.

Does IEC 61000-5-2 specify voltage limits for industrial environments?

No, the standard doesn’t provide specific voltage limits. Instead, it defines test levels and criteria for equipment immunity to voltage variations.

How do I know which test levels apply to my equipment?

Test levels are determined based on equipment sensitivity. Consult the standard or an EMC expert for guidance tailored to your specific needs.

Is compliance with IEC 61000-5-2 about preventing equipment damage or just operational disruptions?

It’s about both. Compliance ensures equipment doesn’t get damaged or disrupted by voltage variations in industrial settings.

Is there a standard for residential or commercial equipment similar to IEC 61000-5-2?

Yes, there are other standards like IEC 61000-4 series that address EMC for various environments, including residential and commercial.