How to Select Overload Relay for Motor – Expert Sizing Rules, Settings & Common Mistakes

Knowing how to select overload relay for motor protection is one of the most important skills for electrical engineers, technicians, and industrial electricians. An incorrectly selected overload relay can cause nuisance tripping, overheating, motor winding damage, or complete motor failure. Despite its importance, overload relay selection is often done using guesswork rather than proper engineering rules.

This detailed guide explains how to select overload relay for motor applications using practical sizing rules, correct current settings, motor data interpretation, and real-world mistakes to avoid. The approach is field-tested, standards-aligned, and written for practical implementation.

Table of Contents

What Is an Overload Relay and Why It Matters

An overload relay is a protective device designed to safeguard motors against prolonged overcurrent conditions. Unlike short circuits, overloads are moderate overcurrents that persist over time, causing gradual heating of the motor windings.

When you select overload relay for motor protection correctly, it performs three critical functions:

- Detects thermal stress due to excess current

- Trips the control circuit before insulation damage occurs

- Allows safe motor operation during temporary starting current

Overload relays do not protect against short circuits. They work alongside fuses or circuit breakers, forming a complete motor protection system.

Know more about Motor Overload Protection Chart: Important Concepts

Understanding Motor Nameplate Data Before Selection

Before attempting to select overload relay for motor use, the motor nameplate must be studied carefully. The overload relay setting depends directly on rated motor current and operating conditions.

Key nameplate parameters include:

- Rated current (FLA or rated amps)

- Voltage and frequency

- Power factor

- Efficiency class

- Service factor

- Duty type

The rated current is the most important value when sizing an overload relay.

Types of Overload Relays Used in Motor Protection

Different industrial applications require different overload relay technologies. Understanding these types helps you select overload relay for motor systems more accurately.

Thermal Overload Relays

Thermal overload relays use bimetallic strips that bend when heated by motor current. They are simple, reliable, and widely used in conventional motor starters.

Know more about Thermal Overload Relay: Working Principle, Types and Important Settings Calculation

Electronic Overload Relays

Electronic overload relays use current transformers and microelectronics to measure current precisely. They offer better accuracy, phase loss detection, and adjustable trip classes.

Solid State Overload Relays

Solid state relays provide fast response, digital settings, and integration with PLC and SCADA systems. These are common in modern automation panels.

How to Select Overload Relay for Motor Step by Step

To select overload relay for motor applications correctly, follow this structured method.

Step 1: Identify Motor Full Load Current

Always use the motor nameplate current instead of calculating it manually unless the nameplate is unavailable. Nameplate current already accounts for efficiency and power factor.

Step 2: Choose the Correct Overload Relay Range

Overload relays are manufactured with adjustable current ranges. The motor rated current must fall within the middle of this range for accurate operation.

Step 3: Consider Motor Service Factor

Service factor affects how the overload relay should be set. Motors with higher service factors can tolerate slightly higher current before tripping.

Step 4: Select Appropriate Trip Class

Trip class defines how fast the overload relay responds to overcurrent. This selection depends on motor starting characteristics.

Know more about What Are the Applications of Overcurrent Relays in Power Systems?

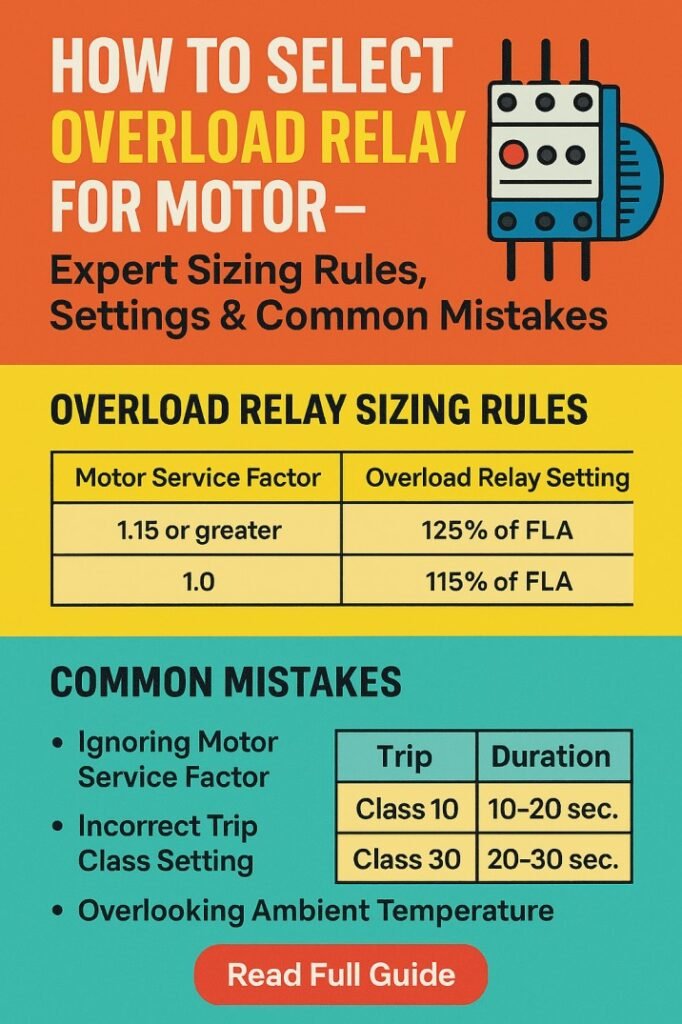

Overload Relay Sizing Rules Explained Clearly

The following table summarizes standard industry rules used to select overload relay for motor protection.

| Motor Condition | Overload Relay Setting |

|---|---|

| Continuous duty, SF ≥ 1.15 | 125% of rated current |

| Continuous duty, SF < 1.15 | 115% of rated current |

| Intermittent duty motor | 110% to 115% |

| High inertia load | Use higher trip class |

| Frequent starts | Electronic relay preferred |

These values are aligned with IEC and NEC recommendations and work well in practical installations.

Example Calculation for Overload Relay Selection

Assume a three-phase motor with the following data:

| Parameter | Value |

|---|---|

| Rated power | 11 kW |

| Voltage | 415 V |

| Rated current | 21 A |

| Service factor | 1.15 |

| Duty | Continuous |

Since the service factor is 1.15, the overload relay setting should be:

21 A × 1.25 = 26.25 A

To select overload relay for motor protection in this case, choose a relay with an adjustable range of 24–32 A and set it to 26 A.

Know more about What Are Different Types of Overcurrent Relays? Best Guide

Selecting the Correct Trip Class for Motors

Trip class selection is often ignored, leading to startup trips or delayed protection.

| Trip Class | Typical Application |

|---|---|

| Class 10 | Standard motors, pumps |

| Class 20 | Conveyors, compressors |

| Class 30 | High inertia loads, crushers |

When you select overload relay for motor applications with heavy loads, a higher trip class prevents nuisance tripping during startup.

Single Phasing and Phase Imbalance Protection

Modern overload relays offer phase failure and imbalance protection. These features are critical for three-phase motors, as single phasing can damage motors within minutes.

Electronic overload relays detect:

- Phase loss

- Current imbalance

- Extended underload conditions

Including these protections improves motor life and system reliability.

Common Mistakes While Selecting Overload Relay for Motor

Even experienced technicians make avoidable errors when selecting overload relays. Understanding these mistakes helps ensure reliable motor protection.

- Setting overload relay equal to breaker rating

- Ignoring service factor value

- Using calculated current instead of nameplate current

- Selecting too wide current range

- Choosing wrong trip class

- Bypassing overload relay during testing and forgetting to reconnect

Avoiding these mistakes significantly improves motor safety.

Use our online tool Motor Overload Setting Calculator for Single and Three Phase Motors

Overload Relay Coordination with MCCB and Contactor

Proper coordination ensures that only the faulty section trips during a fault. When you select overload relay for motor systems, ensure the following coordination:

- MCCB handles short circuits

- Contactor switches load current

- Overload relay handles thermal protection

The overload relay should always trip before motor insulation damage but after normal starting current subsides.

Environmental and Installation Factors

Environmental conditions affect overload relay performance and should be considered during selection.

Factors include:

- Ambient temperature

- Panel ventilation

- Mounting orientation

- Altitude above sea level

Electronic overload relays perform better in varying temperatures compared to thermal types.

Maintenance and Testing Best Practices

Even after you select overload relay for motor protection correctly, periodic testing is essential.

Recommended practices:

- Verify current settings annually

- Check trip function during shutdown

- Inspect wiring and terminals

- Review motor load conditions

Regular maintenance ensures consistent protection throughout the motor’s life.

Know everything about 3 Phase Motor Overload Relay Setting – Accurate Protection for Your Motor

Final Thoughts on Overload Relay Selection

Learning how to select overload relay for motor protection is not just about matching current values. It requires understanding motor behavior, operating conditions, and protection coordination. When selected and set properly, an overload relay becomes the motor’s first line of defense against thermal damage.

By following the sizing rules, setting guidelines, and practical tips explained in this guide, you can confidently select overload relay for motor applications in industrial, commercial, and utility environments with long-term reliability and safety.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#HowToSelectOverloadRelayForMotor, #OverloadRelaySelection, #MotorProtectionGuide, #ElectricalEngineeringTips, #MotorOverloadRelay, #IndustrialElectrical, #MotorSafety, #ElectricalDesign, #ControlPanelDesign, #AutomationEngineering