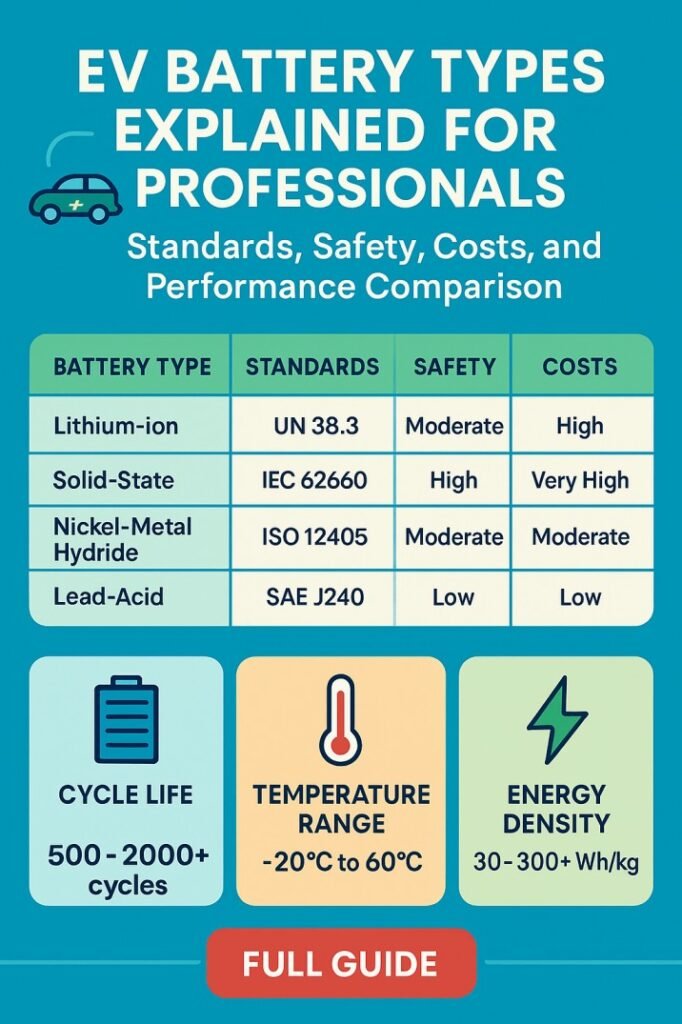

EV Battery Types Explained for Professionals: Standards, Safety, Costs, and Performance Comparison

Electric vehicles are transforming transport, and understanding ev battery types is now essential for engineers, designers, and energy professionals. Battery chemistry directly affects vehicle range, charging speed, thermal behavior, lifecycle cost, and safety compliance. As global standards evolve and performance expectations rise, professionals must evaluate batteries not only by energy density but also by durability, supply chain stability, and regulatory alignment.

Table of Contents

This guide provides a practical technical breakdown of ev battery types, focusing on real-world engineering tradeoffs rather than marketing claims.

Use our online tool for free Battery Cable Size Calculator – Instantly Find the Right Wire Gauge for Any Battery Setup

Why EV Battery Chemistry Matters in System Design

Battery selection influences the entire vehicle architecture. Pack voltage, cooling strategy, battery management system logic, and even crash structures depend on chemistry choice. Different ev battery types offer different internal resistance, thermal runaway characteristics, and depth of discharge limits. These parameters affect drivetrain efficiency, warranty modeling, and homologation testing.

For commercial fleets, chemistry also impacts total cost of ownership. For passenger vehicles, energy density and safety margins often take priority. Professionals must balance these competing requirements.

Main EV Battery Types Used Today

Several lithium-ion variants dominate the market. While solid-state technology is emerging, most current vehicles rely on mature liquid-electrolyte cells.

Know more about IEC Standard for VRLA Battery – Complete Guide to Design, Testing, and Performance

Comparison of Major EV Battery Types

| Battery Chemistry | Common Abbreviation | Energy Density (Wh/kg) | Cycle Life | Thermal Stability | Cost Level | Typical Applications |

|---|---|---|---|---|---|---|

| Lithium Iron Phosphate | LFP | 120–160 | Very High | Excellent | Low | Buses, entry EVs, fleet cars |

| Nickel Manganese Cobalt | NMC | 150–220 | High | Moderate | Medium | Passenger EVs |

| Nickel Cobalt Aluminum | NCA | 200–260 | Medium | Moderate | High | Long-range EVs |

| Lithium Titanate | LTO | 70–90 | Extremely High | Outstanding | Very High | Fast-charge fleets |

| Solid-State (Emerging) | SSB | 300+ (target) | Unknown | Potentially High | Very High | Future premium EVs |

Each of these ev battery types presents distinct advantages depending on performance goals and regulatory requirements.

Know more about Why Are Lithium Batteries Dangerous: 7 Hidden Risks You Must Know

Lithium Iron Phosphate Batteries

LFP chemistry has gained strong momentum in recent years. It uses iron and phosphate instead of cobalt or nickel, reducing cost volatility and ethical sourcing concerns. Among current ev battery types, LFP offers superior thermal stability and long cycle life. Discover everything about How to Recycle Lithium Ion Batteries: 7 Powerful Steps for a Cleaner Future

Key Characteristics

- Lower energy density compared to NMC and NCA

- Strong resistance to thermal runaway

- Long lifespan under frequent charging

- Lower raw material cost

LFP packs are heavier for the same range, but their safety profile simplifies cooling system design. Many manufacturers now use LFP in standard-range vehicles and commercial fleets where durability outweighs maximum range.

Learn more about tesla insurance in florida

Nickel Manganese Cobalt Batteries

NMC remains one of the most balanced ev battery types. By adjusting nickel, manganese, and cobalt ratios, manufacturers can tune energy density and lifespan.

Technical Strengths

- Good balance of power and energy density

- Suitable for both short and long range vehicles

- Mature manufacturing ecosystem

However, NMC cells are more sensitive to overheating than LFP. Thermal management systems must be robust. Cobalt supply constraints also influence long-term cost forecasts. Know more about The Rise of LFP Batteries: Are They the Future of EVs?

Nickel Cobalt Aluminum Batteries

NCA chemistry delivers some of the highest energy density among commercial ev battery types. It is widely used in premium long-range electric vehicles.

Engineering Considerations

- High specific energy supports longer driving range

- Requires precise battery management

- Greater sensitivity to overcharge and overheating

Cooling design, cell balancing, and voltage monitoring are critical. NCA is attractive where performance matters most, but safety engineering must be meticulous.

Get complete information about level 2 charger home installation cost

Lithium Titanate Batteries

LTO is a niche but technically impressive option among ev battery types. It replaces the graphite anode with lithium titanate, enabling extremely fast charging and exceptional cycle life.

Performance Profile

- Ultra-fast charging capability

- Very long lifespan

- Wide operating temperature range

The drawback is low energy density, making packs bulky. LTO suits buses, industrial vehicles, and applications where downtime must be minimized.

Use our online tool EV Range Calculator: Instantly Estimate Your Electric Car Driving Distance

Emerging Solid-State Batteries

Solid-state designs replace liquid electrolyte with a solid material. These next-generation ev battery types promise major improvements in energy density and safety.

Potential Benefits

- Higher theoretical energy density

- Lower fire risk

- Reduced cooling requirements

Manufacturing scalability and interface stability remain challenges. Commercial adoption is expected later this decade.

Safety Standards Governing EV Battery Types

Safety compliance is non-negotiable. Different ev battery types must pass international abuse and performance tests before entering production.

Important Standards

- UN 38.3 for transport safety

- IEC 62660 for performance testing

- ISO 26262 for functional safety

- SAE J2464 for abuse testing

- UL 2580 for EV battery systems

LFP often performs better in nail penetration and thermal propagation tests. High-nickel chemistries require more advanced containment strategies.

Uncover insights on ev charger for hotels

Thermal Management Requirements

Heat generation varies significantly across ev battery types. Thermal design affects charging rates, aging, and safety.

| Chemistry | Heat Generation | Cooling Complexity | Thermal Runaway Risk |

|---|---|---|---|

| LFP | Low | Simple | Low |

| NMC | Medium | Moderate | Medium |

| NCA | High | Advanced | Medium to High |

| LTO | Low | Simple | Very Low |

Efficient cooling improves cycle life and reduces degradation. Liquid cooling remains standard in high-energy packs.

Cost Comparison of EV Battery Types

Battery cost per kilowatt-hour depends on raw materials, manufacturing scale, and pack design.

| Chemistry | Material Cost Trend | Pack Cost Level | Lifecycle Cost |

|---|---|---|---|

| LFP | Stable | Low | Very Favorable |

| NMC | Fluctuating | Medium | Moderate |

| NCA | High Nickel Exposure | High | Moderate |

| LTO | Expensive Materials | Very High | Favorable for High Cycles |

LFP currently leads in cost efficiency for high-volume production.

Dive deeper into ev charger not working

Performance Comparison in Real Applications

Performance depends on driving profile, climate, and charging behavior. Among ev battery types, tradeoffs appear in range, power delivery, and aging.

Range and Energy Density

- NCA typically provides the longest range

- NMC offers balanced range and cost

- LFP provides shorter range but longer life

Charging Speed

- LTO supports the fastest charging

- NMC and NCA allow fast charging with proper cooling

- LFP fast charging is improving with new cell designs

Degradation Behavior

LFP degrades more slowly under frequent cycling. High-nickel chemistries may lose capacity faster at high temperatures.

Explore details on ev battery degradation calculator

Environmental and Supply Chain Considerations

Material sourcing affects sustainability. Among ev battery types, cobalt-free chemistries reduce ethical and geopolitical risks.

- LFP avoids cobalt and nickel

- NMC and NCA depend on critical minerals

- Recycling technologies are improving recovery rates

Regulations in Europe increasingly require lifecycle transparency and recycling efficiency.

Choosing the Right Battery Type for a Project

Selection should follow engineering priorities rather than trends. When comparing ev battery types, professionals should evaluate:

- Required vehicle range

- Weight limitations

- Charging infrastructure

- Safety certification targets

- Expected duty cycle

- Total cost of ownership

Fleet operators often choose LFP for durability. Premium vehicles may favor NCA for range.

Find out more about home ev charging station installation

Future Outlook for EV Battery Types

Battery innovation is accelerating. Silicon anodes, lithium metal cells, and solid electrolytes may redefine ev battery types in the coming decade. However, incremental improvements to LFP and NMC are likely to dominate near-term production.

Manufacturers are also optimizing pack structures such as cell-to-pack and structural battery designs, which influence overall vehicle efficiency regardless of chemistry.

Final Technical Takeaway

Understanding ev battery types requires a system-level perspective. Energy density alone does not determine suitability. Safety behavior, thermal management needs, supply chain risk, and lifecycle economics are equally critical. LFP leads in safety and cost stability. NMC provides balance. NCA maximizes range. LTO excels in fast charging and longevity. Solid-state remains a future solution with high potential.

Try our free online tool today ev charger cable size calculator

For engineering professionals, the best battery choice is the one aligned with performance targets, regulatory demands, and long-term operational strategy.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#EVBatteryTypes, #ElectricVehicleBatteries, #BatteryStandards, #LithiumIonBatteries, #EVEngineering, #BatterySizing, #EnergyStorageSystems, #EVSafetyCodes, #AutomotiveBatteryTech, #HighVoltageSystems

I just like the helpful information you provide in your articles