Electrical Panel Design Calculations: A Complete Guide

Understanding Electrical Panel Design Calculations

Electrical panel design calculations are essential for ensuring safe and efficient power distribution. A well-designed electrical panel prevents overloads, minimizes energy losses, and improves system reliability.

Designing an electrical panel involves multiple calculations, including load estimation, breaker sizing, conductor sizing, and voltage drop analysis. These calculations are necessary for industrial, commercial, and residential installations.

This guide covers electrical panel design calculations, step-by-step, ensuring compliance with safety standards and energy efficiency requirements.

Table of Contents

Table of Contents

Importance of Electrical Panel Design Calculations

Electrical panel design calculations help in:

- Determining circuit breaker ratings for overload and short-circuit protection.

- Selecting wire sizes to handle the expected load.

- Ensuring proper voltage levels at connected devices.

- Preventing overheating and electrical faults.

- Complying with NEC, IEC, and IEEE standards.

Accurate calculations improve system reliability and reduce electrical failures.

Key Electrical Panel Design Calculations

1. Load Calculation for Electrical Panel

The first step in electrical panel design calculations is determining the total electrical load.

The formula for calculating total load is:

Use an Electricity Load Calculator in kW for Home to simplify this process for residential applications.

Factors Affecting Load Calculation

- Connected Load: The sum of all electrical devices.

- Demand Factor: A percentage of the total connected load that is expected to run simultaneously.

- Diversity Factor: The ratio of total load to maximum demand at a given time.

A Solar Power Load Calculator helps determine additional solar power contributions for hybrid electrical systems.

2. Circuit Breaker Sizing

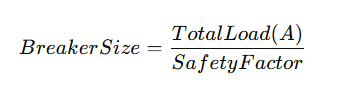

Selecting the right circuit breaker prevents overloading and short circuits. The breaker size is calculated as:

For most applications, the safety factor is 1.25 (or 125%).

Example: If a circuit has a load of 80A, the breaker size should be: 80A×1.25=100A

Using an Electrical Service Calculator ensures proper breaker selection for service panels.

3. Wire Size Calculation

Selecting the correct wire size is essential to prevent voltage drop and overheating. The formula is:

A Wiring Size Calculator simplifies this process for different applications.

Key Factors in Wire Sizing:

- Current Load (Amps)

- Distance from Source (ft)

- Voltage Drop Limit (usually 3%)

- Conductor Material (Copper or Aluminum)

Larger loads and longer distances require thicker conductors to maintain efficiency.

4. Voltage Drop Calculation

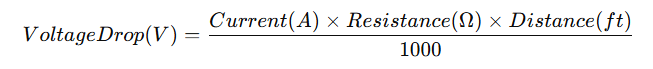

Voltage drop must be kept below 3% for efficiency. The voltage drop formula is:

Excessive voltage drop leads to poor performance and energy loss.

For long distances, consider:

- Increasing conductor size

- Using higher voltage distribution

An Electrical Load Calculator helps estimate the correct wire sizes for voltage drop minimization.

5. Generator Sizing for Electrical Panels

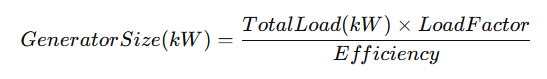

When designing an electrical panel for backup power, proper generator sizing is crucial. The generator size is calculated as:

Use a Generator Size Calculator to determine the right generator capacity.

Key Considerations:

- Starting vs. Running Load: Motors require extra power at startup.

- Load Type: Resistive loads (heaters) vs. Inductive loads (motors, transformers).

- Phase and Voltage Compatibility: Match with panel requirements.

For commercial and industrial setups, a Select Electrical Load Calculator and Generator Sizing tool ensures accurate calculations.

Electrical Panel Layout and Component Selection

1. Busbar and Conductor Sizing

Busbars distribute power inside the panel. Their size depends on:

- Current Rating (A)

- Material (Copper or Aluminum)

- Short Circuit Withstand Capacity

2. Protection Devices

Every electrical panel requires protection against faults:

- MCBs (Miniature Circuit Breakers): Protect against overloads and short circuits.

- MCCBs (Molded Case Circuit Breakers): Suitable for higher loads.

- RCCBs (Residual Current Circuit Breakers): Prevent electrical shocks.

3. Enclosure Selection

The panel enclosure should match environmental conditions:

- NEMA 1: Indoor use.

- NEMA 3/4/12: Outdoor, dustproof, or waterproof enclosures.

- NEMA 7/9: Explosion-proof panels for hazardous areas.

Final Steps in Electrical Panel Design

1. Short Circuit and Fault Current Calculation

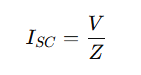

Short circuit current is calculated using:

Where:

- V = System voltage

- Z = Total impedance of the system

Fault current calculations ensure proper breaker and conductor selection. Read more about fault current calculation and steps involved in calculation in detail here.

2. Compliance with Electrical Codes

Electrical panel design must comply with:

- National Electrical Code (NEC)

- International Electrotechnical Commission (IEC)

- IEEE Standards

Using an Electrical Service Calculator ensures panels meet regulations.

Conclusion

Electrical panel design calculations are critical for safe and efficient power distribution. By following proper load calculations, breaker sizing, wire selection, and voltage drop considerations, you can design a reliable electrical panel.

You can use the below tools for estimating your Electrical Panel Design Calculations.

- Wiring Size Calculator

- Generator Size Calculator

- Electrical Service Calculator

- Electricity Load Calculator in kW for Home

- Solar Power Load Calculator

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights to get the latest updates in Electrical Engineering.

ElectricalPanelDesign, #PanelDesignCalculations, #ElectricalEngineering, #ControlPanelDesign, #PowerDistribution, #ElectricalSafety, #LoadCalculation, #CircuitDesign, #Switchgear, #IndustrialElectrical, #ElectricalPanels, #PowerSystemDesign, #ElectricalLoad, #PanelBoard, #Automation