Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

Busbars are the backbone of power distribution systems in substations, switchgear, and industrial plants. Their mechanical and thermal strength directly affects system safety, reliability, and fault performance. A properly conducted busbar stability test ensures that busbars can withstand short-circuit forces, thermal stress, and operational loads without deformation or failure. This article explains the complete procedure in a practical, step-by-step manner, focusing on field applicability and compliance with engineering standards.

Table of Contents

A stability test is not just a formality. It is a critical verification process that protects equipment, personnel, and continuity of power supply, especially in high-fault-current environments.

What Is a Busbar Stability Test

A busbar stability test evaluates the ability of busbars to remain mechanically and thermally stable under normal operating conditions and during short-circuit events. During faults, very high electromagnetic forces act on busbars, causing bending, vibration, or displacement. If the design or installation is weak, this can lead to insulation failure or catastrophic damage.

Find out more about iec 61439 busbar clearance

The busbar stability test confirms that the busbar system can safely handle these stresses within allowable limits defined by international standards and design calculations.

Importance of Busbar Stability Testing

The significance of a busbar stability test increases with system voltage and fault level. In modern power systems, short-circuit currents can reach extremely high values within milliseconds.

Key reasons for performing a stability test include:

- Verification of mechanical strength against electrodynamic forces

- Confirmation of thermal withstand capability during faults

- Prevention of busbar displacement and insulation damage

- Compliance with IEC and IEEE standards

- Increased reliability and service life of switchgear

Without a proper busbar stability test, even a well-designed electrical system can fail under fault conditions.

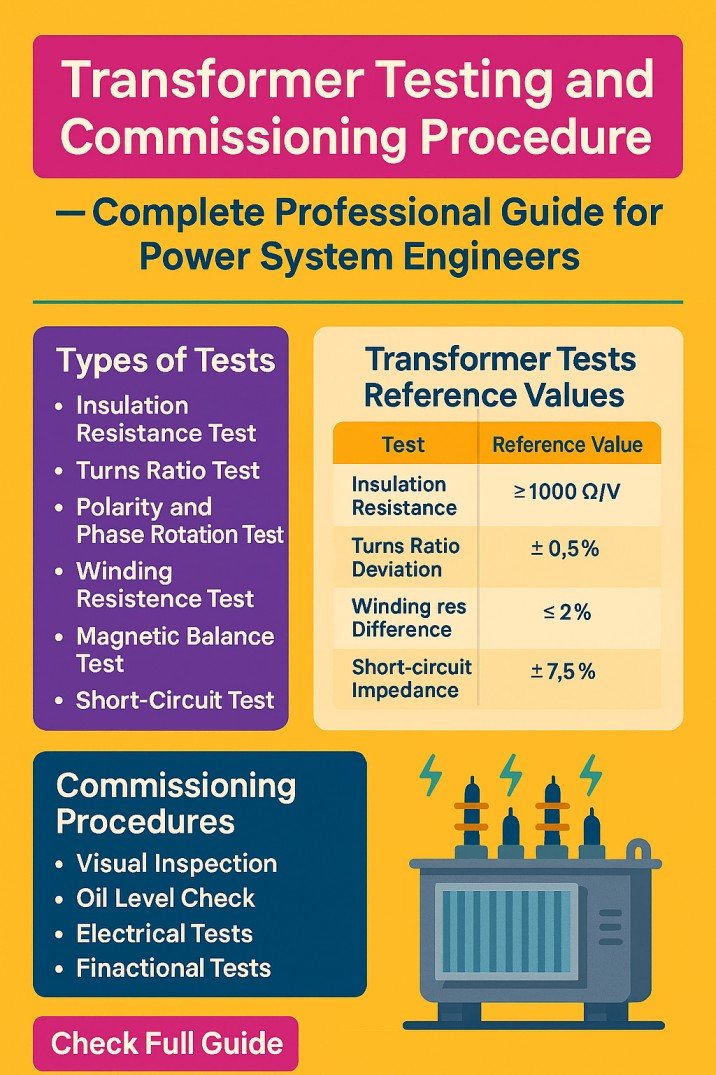

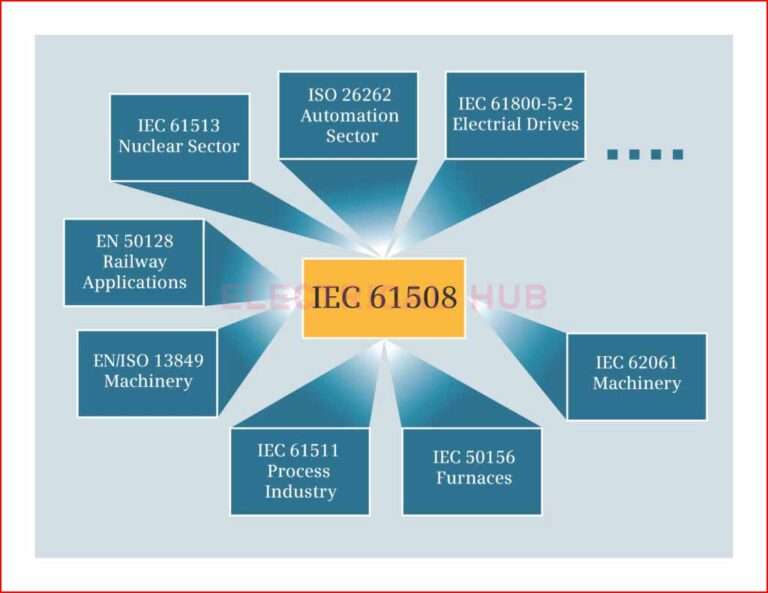

Applicable Standards for Busbar Stability Test

The procedure and acceptance criteria for a stability test are defined in recognized international standards. These standards ensure consistency and safety across installations.

| Standard | Description |

|---|---|

| IEC 61439 | Low-voltage switchgear and controlgear assemblies |

| IEC 62271 | High-voltage switchgear and controlgear |

| IEEE C37 | Power switchgear testing and performance |

| IEC 60865 | Short-circuit forces on busbars |

Following these standards ensures that the busbar stability test results are technically valid and globally acceptable.

Get complete information about iec standard for busbar sizing

Types of Busbar Stability Considered

A complete busbar stability test considers more than one aspect of performance. Each type of stability addresses a different stress condition.

- Mechanical stability

- Thermal stability

- Electrodynamic stability

Mechanical stability focuses on physical strength, while thermal stability checks temperature rise during faults. Electrodynamic stability evaluates forces generated by high short-circuit currents.

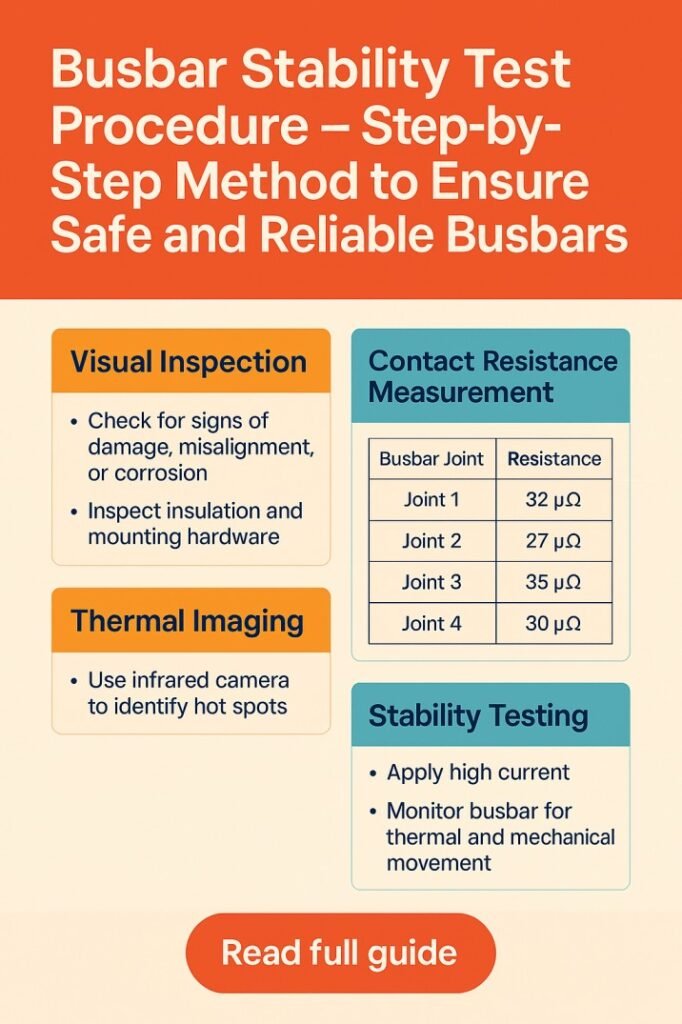

Pre-Test Preparation and Inspection

Before performing a stability test, proper preparation is essential. Skipping this stage can lead to inaccurate results or unsafe testing conditions.

Initial checks include:

- Verification of busbar material, size, and spacing

- Inspection of supports, clamps, and insulators

- Confirmation of tightening torque for all connections

- Review of design drawings and short-circuit calculations

These steps ensure that the busbar system is installed exactly as designed before applying test conditions.

Read in detail about iec 61439 busbar calculation

Step-by-Step Busbar Stability Test Procedure

The following step-by-step method explains how a busbar stability test is typically conducted in laboratories or simulated through calculations for site installations.

Step 1: Short-Circuit Current Assessment

The first step in a busbar stability test is determining the prospective short-circuit current at the installation point. This value depends on transformer rating, system impedance, and network configuration.

Accurate short-circuit current data is critical because all force and temperature calculations are based on it.

Step 2: Calculation of Electrodynamic Forces

During a short circuit, parallel busbars experience repulsive or attractive forces. These forces are calculated using standardized formulas provided in IEC 60865.

The stability test checks whether the busbars and their supports can withstand these forces without permanent deformation.

Step 3: Thermal Withstand Evaluation

Thermal stability is evaluated by calculating the temperature rise caused by short-circuit current over a specified duration, usually 1 second.

This part of the busbar stability test ensures that:

- The busbar does not exceed permissible temperature limits

- Insulation materials remain intact

- No annealing or loss of mechanical strength occurs

Know more about IEC Standard for Busbar Clearance

Step 4: Mechanical Support Verification

Busbar supports play a major role in stability. The stability test includes checking:

- Spacing between supports

- Strength of insulating materials

- Fixing methods and hardware

Supports must resist bending moments and vibrations during fault conditions.

Step 5: Physical Test or Type Test (If Applicable)

In type-tested assemblies, a physical busbar stability test may be conducted in a certified laboratory. A controlled short-circuit current is applied, and the busbars are inspected afterward.

Acceptance criteria include:

- No visible deformation

- No cracks in insulators

- No loosening of connections

Step 6: Post-Test Inspection and Documentation

After completing the stability test, a detailed inspection is performed. All observations, measurements, and calculations are documented for future reference and audits.

Find out more about contact resistance test acceptable value for busbar

Typical Acceptance Criteria

Acceptance criteria define whether a busbar stability test is successful. These limits are based on standards and design assumptions.

| Parameter | Acceptance Limit |

|---|---|

| Mechanical deformation | No permanent deformation |

| Temperature rise | Within standard limits |

| Insulator condition | No cracks or damage |

| Connection tightness | No loosening |

Meeting these criteria confirms that the busbar system is safe and reliable.

Common Issues Found During Busbar Stability Test

A stability test often reveals design or installation weaknesses that may not be visible during normal operation.

Common issues include:

- Insufficient support spacing

- Undersized busbar cross-section

- Poor-quality insulating materials

- Improper tightening of joints

Identifying these issues early prevents costly failures in service.

Best Practices for Reliable Busbar Stability

To ensure long-term reliability, engineers should integrate busbar stability test considerations at the design stage rather than treating them as an afterthought.

Recommended best practices:

- Use conservative short-circuit current assumptions

- Select high-strength support materials

- Maintain uniform spacing between busbars

- Periodically inspect busbar systems in service

These practices enhance the effectiveness of any stability test.

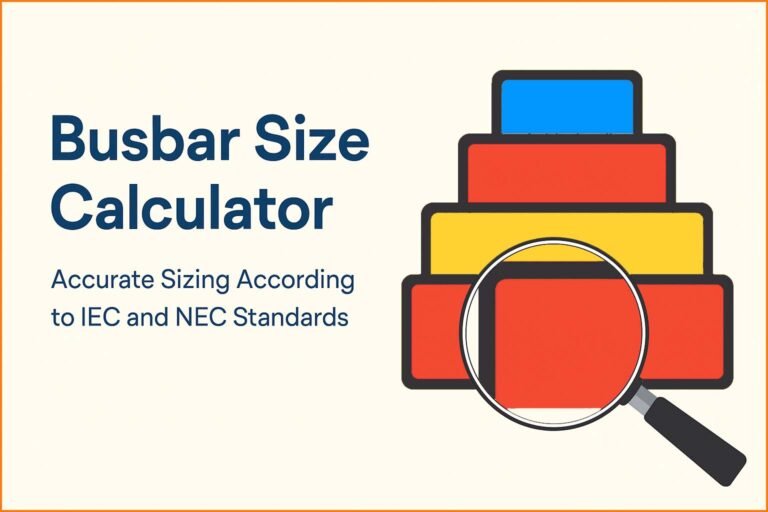

Use our online tool Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Difference Between Design Calculation and Physical Testing

In many installations, a stability test is verified through calculations instead of physical testing. Both methods are acceptable when performed correctly.

| Method | Application |

|---|---|

| Design calculation | Site-installed or custom systems |

| Physical type test | Standardized switchgear assemblies |

Calculations are practical for most projects, while physical tests provide higher confidence for mass-produced systems.

Conclusion

A busbar stability test is a vital engineering process that ensures power distribution systems can withstand extreme electrical and mechanical stresses. By following a structured step-by-step procedure, engineers can verify mechanical strength, thermal performance, and overall reliability of busbars.

From initial short-circuit assessment to post-test inspection, each stage of the stability test contributes to system safety and compliance. Proper testing not only prevents failures but also extends equipment life and improves operational confidence.

Find out more about High Impedance Busbar Protection Explained with Example Calculations

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BusbarStabilityTest,#BusbarStabilityTestProcedure,#BusbarTesting,#ElectricalBusbar,#SubstationTesting,#PowerSystemTesting,#BusbarDesign,#ElectricalEngineering,#ShortCircuitTest,#HVTesting