Busbar Sizing Rule of Thumb: Practical Engineer’s Guide for Accurate Panel Busbar Selection

Electrical panels depend on reliable current distribution, and the busbar sizing rule of thumb remains a trusted starting point for engineers working under real project constraints. This practical method helps estimate conductor cross-section quickly while maintaining safe temperature rise and acceptable voltage drop. When used with sound engineering judgment, it prevents costly undersizing and reduces design iterations during panel fabrication.

Table of Contents

Why Busbar Sizing Matters in Real Installations

A panel busbar carries the full load current and often operates continuously. If the cross-section is too small, excessive heat builds up, insulation life reduces, and system reliability suffers. Oversizing, on the other hand, increases copper or aluminum cost and panel footprint. The busbar sizing rule of thumb offers a balanced approach that aligns with current density limits and thermal performance without waiting for detailed simulations. Read in detail about iec 61439 busbar calculation

In practical switchboards, engineers must also consider enclosure ventilation, ambient temperature, and duty cycle. These real-world variables influence allowable current density, which is the foundation of quick sizing estimates.

Get complete information about iec standard for busbar sizing

Understanding the Current Density Concept

The basic idea behind the busbar sizing rule of thumb is to select a cross-sectional area that keeps current density within safe limits. Current density is simply the load current divided by the busbar area. For most indoor LV panels with adequate ventilation, commonly accepted values fall within a predictable range.

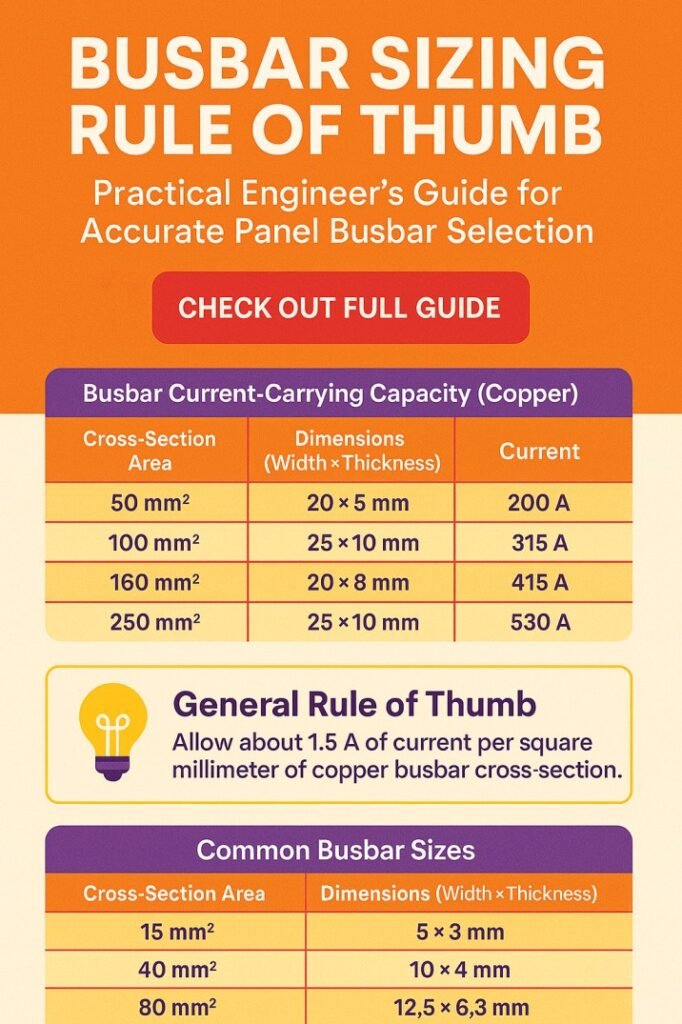

Typical guidance used in workshops and field design reviews is summarized below.

Table 1: Common Current Density Values for Panel Busbars

| Busbar Material | Typical Current Density (A/mm²) | Application Notes |

|---|---|---|

| Copper | 1.2 to 1.6 | Enclosed panels, continuous duty |

| Copper | 1.6 to 2.0 | Open air or well-ventilated boards |

| Aluminum | 0.8 to 1.2 | Enclosed panels with moderate temperature |

| Aluminum | 1.2 to 1.5 | Short duty or improved cooling |

These ranges support a quick decision during early panel design. Final selection should always be verified against temperature rise limits and manufacturer data.

Find out more about iec 61439 busbar clearance

Applying the Busbar Sizing Rule of Thumb Step by Step

In practice, engineers first determine the maximum load current expected on the main bus. Next, they select a conservative current density based on material and enclosure conditions. Dividing the current by the chosen density provides the required cross-sectional area.

For example, assume a main incomer current of 1600 A using copper in a typical indoor switchboard. If a current density of 1.4 A/mm² is selected, the required area becomes:

Required Area = 1600 ÷ 1.4 ≈ 1143 mm²

The engineer can then choose a standard flat bar arrangement that meets or exceeds this value. This workflow demonstrates how the busbar sizing rule of thumb speeds up design while keeping safety margins intact.

Find out more about Busbar Size Calculator – Accurate Sizing According to IEC and NEC Standards

Selecting Standard Busbar Dimensions

After calculating area, the next task is mapping the result to available bar sizes. Standard copper flats are commonly available in widths from 25 mm to 100 mm with varying thickness.

Table 2: Example Standard Copper Busbar Combinations

| Width (mm) | Thickness (mm) | Area per Bar (mm²) | Quantity | Total Area (mm²) |

|---|---|---|---|---|

| 50 | 10 | 500 | 2 | 1000 |

| 60 | 10 | 600 | 2 | 1200 |

| 80 | 10 | 800 | 2 | 1600 |

| 100 | 10 | 1000 | 2 | 2000 |

In the earlier example, two bars of 60 × 10 mm provide 1200 mm², which exceeds the calculated requirement and supports thermal stability.

Factors That Influence the Final Selection

While the electrical busbar sizing rule of thumb is reliable, experienced engineers adjust the estimate using practical considerations. Ambient temperature above 40°C requires derating because heat dissipation becomes less effective. Enclosures with poor airflow also demand lower current density.

Short circuit withstand capability is another important parameter. The busbar must survive thermal and mechanical stress during fault conditions. Increasing thickness or using multiple bars per phase improves rigidity and reduces electrodynamic forces. Surface finish and spacing between phases also affect heat dissipation and creepage distance.

Find all about Busbar Bending Calculation

Voltage drop is usually minimal across short panel busbars, yet high current feeders or long bus runs may require verification. In such cases, checking resistance per meter ensures compliance with design limits.

Copper Versus Aluminum Busbars in Panel Design

Material selection directly impacts the chosen current density. Copper offers lower resistivity, better thermal conductivity, and compact dimensions. Aluminum provides cost savings and lighter weight but requires larger cross-section to carry the same current safely.

When applying the busbar sizing rule of thumb with aluminum, engineers often increase area by 30 to 50 percent compared with copper. Proper joint preparation and use of bi-metallic connectors also become essential to prevent oxidation and heating at terminations.

Installation Practices That Support Accurate Sizing

Correct installation ensures that the estimated size performs as expected in service. Maintain uniform spacing between phases to enhance cooling and reduce magnetic interaction. Tighten all joints to specified torque values to minimize contact resistance. Use suitable insulation supports that withstand operating temperature and fault forces.

Find out more about Busbar Stability Test Procedure – Step-by-Step Method to Ensure Safe and Reliable Busbars

Routine thermographic inspection during commissioning helps validate that the chosen cross-section operates within acceptable temperature rise. If hot spots appear, additional bars or improved ventilation may be required.

When to Move Beyond the Rule of Thumb

Large switchgear assemblies, high ambient sites, or critical process loads often demand detailed thermal calculations or manufacturer verification tests. Software-based temperature rise analysis provides more precise results for complex busbar geometries. Even then, the busbar sizing rule of thumb remains a dependable preliminary check that aligns early design decisions with industry practice.

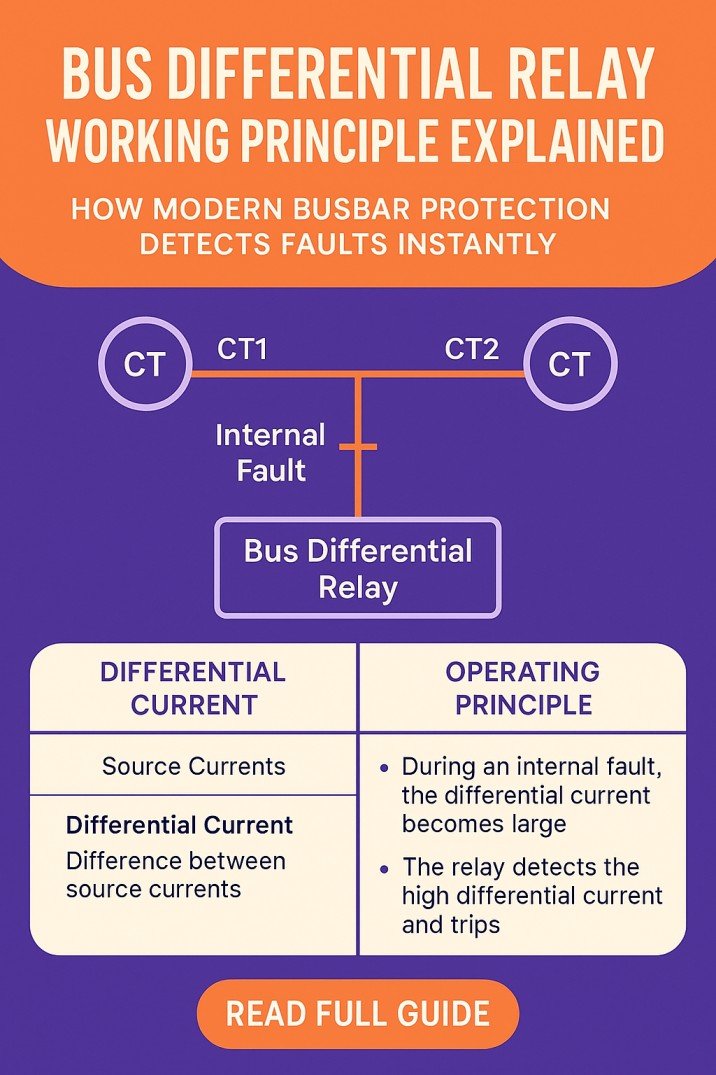

Find out more about High Impedance Busbar Protection Explained with Example Calculations

In day-to-day panel engineering, time pressure and cost control make quick yet safe estimates valuable. By combining current density guidelines, standard bar dimensions, and practical field experience, engineers can achieve reliable current carrying capacity without overspending on materials. This balanced approach keeps panels efficient, compliant, and ready for long-term operation.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#BusbarSizing, #BusbarSizingRuleOfThumb, #ElectricalDesign, #SwitchgearDesign, #BusbarCalculation, #PanelEngineering, #ElectricalStandards, #PowerDistribution, #ElectricalEngineeringTips, #LVSwitchboard