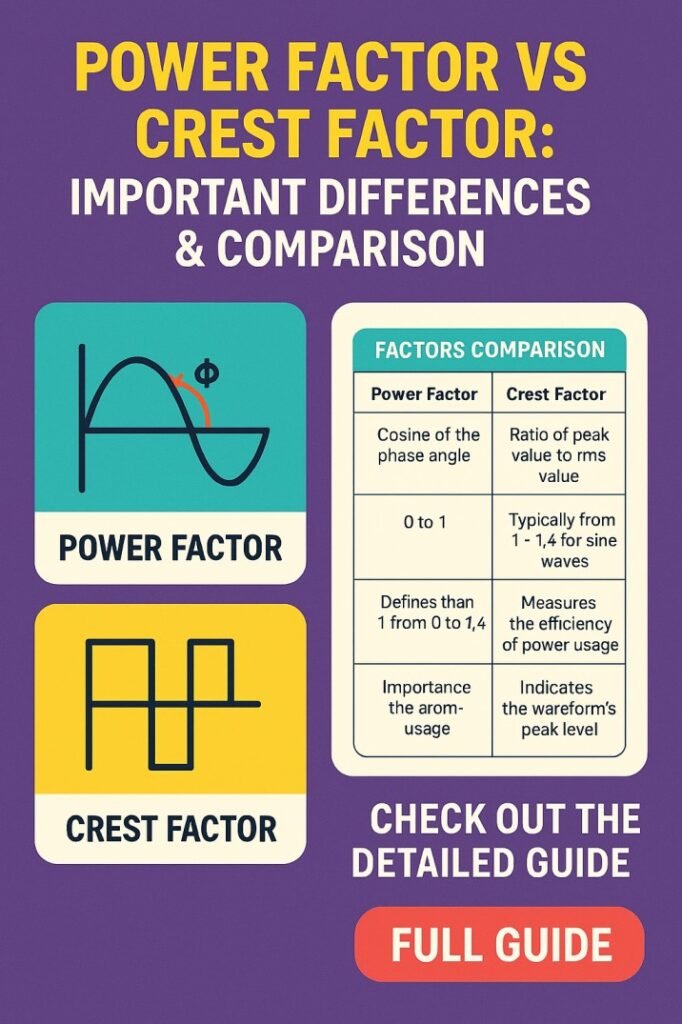

Power Factor vs Crest Factor: Important Differences & Comparison

Power quality is a critical topic in electrical engineering, especially in modern systems where non-linear loads, power electronics, and sensitive equipment are common. Among the many parameters used to evaluate electrical performance, Power Factor vs Crest Factor is a comparison that often creates confusion for engineers, technicians, and energy managers. Although both terms are related to AC electrical systems, they describe very different characteristics of voltage and current behavior.

Table of Contents

This article explains Power Factor vs Crest Factor in a clear and practical way. It covers definitions, formulas, physical meaning, applications, and real-world examples so you can confidently understand when and why each parameter matters.

Understanding Power Factor

Power factor is a measure of how effectively electrical power is being converted into useful work. It represents the relationship between real power and apparent power in an AC circuit.

In simple terms, power factor indicates how efficiently the supplied electrical energy is being used by a load.

Power factor is defined as:

• Ratio of real power to apparent power

• A dimensionless number between 0 and 1

A power factor close to 1 means most of the supplied power is doing useful work. A low value indicates losses due to reactive power or waveform distortion.

Use our online tool for free Power Factor Calculator: Instantly Improve Your Energy Efficiency and Cut Costs

Types of Power Factor

Power factor is generally classified into two main types:

• Displacement power factor

• True power factor

Displacement power factor depends on the phase angle between voltage and current. It is mainly affected by inductive or capacitive loads such as motors and transformers.

True power factor considers both phase displacement and harmonic distortion. It is especially important in systems with non-linear loads like variable frequency drives, UPS systems, and switched-mode power supplies.

Understanding Crest Factor

Crest factor describes the shape of a waveform rather than its efficiency. It is the ratio of the peak value of a waveform to its RMS value.

Crest factor indicates how extreme the peaks of current or voltage are compared to the average effective value.

Crest factor is defined as:

• Ratio of peak value to RMS value

• Always greater than or equal to 1

For a pure sine wave, the crest factor is approximately 1.414. When loads introduce harmonics or sharp current spikes, the crest factor increases.

High crest factor values are common in electronic and non-linear loads and can stress electrical equipment even when RMS values appear normal.

Know more about Peak Value Average Value and RMS Value: Important Concepts

Power Factor vs Crest Factor: Core Conceptual Difference

The key distinction in Power Factor vs Crest Factor lies in what each parameter measures.

Power factor focuses on energy efficiency and how well power is utilized. Crest factor focuses on waveform shape and peak stress on components.

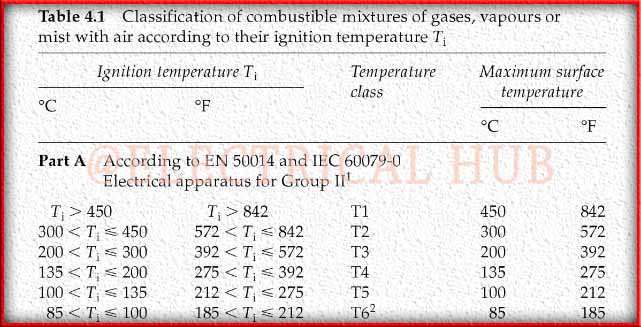

This fundamental difference is summarized in the table below.

| Parameter | Power Factor | Crest Factor |

|---|---|---|

| Primary purpose | Measures power utilization efficiency | Measures waveform peak severity |

| Based on | Real and apparent power | Peak and RMS values |

| Unit | Dimensionless | Dimensionless |

| Indicates | Energy losses and efficiency | Stress on conductors and components |

| Typical concern | Utility billing and energy savings | Equipment sizing and reliability |

Use our online tool for free Power Factor Correction Capacitor Calculator – Complete Technical Guide

Mathematical Comparison

A clear numerical understanding helps distinguish Power Factor vs Crest Factor more effectively.

Power Factor Formula

Power Factor = Real Power (kW) / Apparent Power (kVA)

A lower power factor means higher current for the same useful power, leading to increased losses and voltage drop.

Crest Factor Formula

Crest Factor = Peak Value / RMS Value

Higher crest factor means higher instantaneous current peaks, even if RMS current remains within limits.

| Parameter | Formula | Typical Value |

|---|---|---|

| Power Factor | kW / kVA | 0.7 to 1.0 |

| Crest Factor (sine wave) | Vpeak / Vrms | 1.414 |

| Crest Factor (non-linear load) | Ipeak / Irms | 2 to 5 or higher |

Practical Meaning in Electrical Systems

Understanding Power Factor vs Crest Factor is essential because both affect electrical systems in different ways.

Power factor mainly impacts:

• Energy efficiency

• Electricity billing

• Transformer and generator loading

• Cable sizing due to higher RMS current

Know more about How to Improve Power Factor in Factories and Commercial Buildings: Best Guide

Crest factor mainly impacts:

• Heating of conductors

• Stress on rectifiers and capacitors

• Nuisance tripping of protective devices

• Measurement accuracy of meters

A system can have a good power factor but still suffer from high crest factor due to non-linear loads.

Power Factor vs Crest Factor in Non-Linear Loads

Modern electrical installations contain many non-linear loads such as:

• Variable frequency drives

• LED lighting

• Computers and servers

• Battery chargers

• UPS systems

In these systems, current is drawn in short pulses rather than smoothly. This creates high crest factor even when power factor correction is applied.

This is why Power Factor vs Crest Factor must be evaluated separately. Improving power factor alone does not always reduce peak current stress.

| Load Type | Power Factor | Crest Factor |

|---|---|---|

| Induction motor | Medium to high | Low |

| VFD system | High with correction | High |

| Computer power supply | Moderate | Very high |

| LED drivers | High | High |

Know more about Capacitor Bank Sizing for Power Factor Correction – Step by Step

Impact on Equipment Sizing

One of the most overlooked aspects in the Power Factor vs Crest Factor discussion is equipment sizing.

Transformers, cables, and circuit breakers are rated based on RMS current, but excessive peak currents caused by high crest factor can lead to:

• Overheating

• Insulation stress

• Reduced lifespan

• Unexpected failures

Even if power factor is near unity, a high crest factor can still cause thermal and mechanical stress.

Measurement and Instrumentation Considerations

Accurate measurement is another area where Power Factor vs Crest Factor plays an important role.

Not all meters can accurately measure high crest factor waveforms. Standard RMS meters may underestimate peak values, leading to incorrect assumptions about system safety.

True RMS instruments with high crest factor capability are recommended for:

• Harmonic-rich environments

• Power quality audits

• Data centers and industrial automation

Power factor analyzers and power quality analyzers often display both parameters to provide a complete picture.

Know more about Why Power Factor Correction is Important in Industrial Plants

Power Factor Correction vs Crest Factor Reduction

Power factor correction is commonly achieved using:

• Capacitor banks

• Active power factor correction circuits

These methods improve energy efficiency and reduce reactive power. However, they do not always reduce crest factor.

Reducing crest factor requires:

• Harmonic filtering

• Improved load design

• Proper selection of power supplies

This highlights again why Power Factor vs Crest Factor should never be treated as interchangeable concepts.

When to Focus on Power Factor

Power factor should be the primary concern when:

• Utility penalties are applied

• Large inductive loads are present

• Energy efficiency is a priority

• Transformers and generators are overloaded due to reactive power

Improving power factor reduces operational costs and improves voltage regulation.

When to Focus on Crest Factor

Crest factor becomes critical when:

• Electronic and non-linear loads dominate

• Equipment overheating occurs without high RMS current

• Protective devices trip unexpectedly

• Sensitive electronics fail prematurely

In such cases, waveform quality matters more than energy efficiency alone.

Power Factor vs Crest Factor in Real Applications

In real-world systems, engineers must evaluate Power Factor vs Crest Factor together rather than in isolation.

An industrial plant may have good overall power factor due to correction capacitors, but high crest factor caused by VFDs can still stress cables and switchgear.

Similarly, a data center may show acceptable apparent power usage while suffering from high peak currents that demand oversized infrastructure.

Key Differences at a Glance

| Aspect | Power Factor | Crest Factor |

|---|---|---|

| Focus | Energy efficiency | Waveform peaks |

| Affected by | Phase shift, harmonics | Harmonics, pulse loads |

| Improves billing | Yes | No |

| Improves reliability | Indirectly | Directly |

| Typical mitigation | Capacitors, APFC | Filters, load design |

Know more about Top 10 Power Factor Correction Devices to Buy for Home

Conclusion

The comparison of Power Factor vs Crest Factor is essential for anyone involved in electrical design, operation, or maintenance. Power factor tells you how efficiently electrical power is being converted into useful work, while crest factor reveals how severe current or voltage peaks are within the system.

Both parameters address different risks and performance aspects. A well-designed electrical system considers energy efficiency and waveform quality together. By understanding Power Factor vs Crest Factor, engineers can make better decisions about equipment sizing, power quality improvement, and long-term system reliability.

Ignoring either parameter can lead to higher costs, reduced equipment life, and unexpected failures. Evaluating both ensures a balanced, efficient, and robust electrical system suitable for modern power demands.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#PowerFactorVsCrestFactor, #PowerFactor, #CrestFactor, #PowerQuality, #ElectricalEngineering, #Harmonics, #EnergyEfficiency, #ElectricalCalculations, #IndustrialPower, #PowerSystems