Earth Fault Relay Time Delay Setting: Best Guide

Earth fault relays are essential for protecting electrical systems from damage caused by leakage currents to the ground. They detect abnormal currents and isolate the faulty section to prevent equipment failure or fire hazards. One critical aspect of these relays is the time delay setting. Earth Fault Relay Time Delay Setting ensures the system is safe and prevents unnecessary interruptions.

Table of Contents

What is an Earth Fault Relay?

An earth fault relay monitors the current flowing to the ground. When insulation fails or a fault occurs, the current exceeds a preset value, and the relay trips. This isolates the faulty equipment and protects the rest of the system. Earth fault relays are commonly used in transformers, motors, generators, and distribution panels. They are vital for industrial, commercial, and residential electrical systems. Read in detail about types of transformer protection relays

Importance of Time Delay in Earth Fault Relays

Time delay is the pause before the relay operates after detecting a fault. It prevents tripping for minor or temporary disturbances. Electrical systems often experience short surges or inrush currents when switching on motors or transformers. Without a proper time delay, the relay may trip unnecessarily, causing operational issues and downtime.

Proper time delay settings ensure:

- Reliable protection of equipment

- Reduced nuisance tripping

- Stable operation of the electrical system

Factors Affecting Earth Fault Relay Time Delay Setting

Several factors influence the correct time delay:

| Factor | Impact on Time Delay |

|---|---|

| System Fault Level | High fault currents require shorter delay, while low fault currents need longer delay |

| Load Characteristics | Motors and transformers with high inrush currents need higher delay to avoid false tripping |

| Coordination with Other Relays | Proper coordination prevents simultaneous tripping of upstream and downstream devices |

| Relay Type | Electromechanical and digital relays may have different time delay characteristics |

Uncover insights on high impedance protection

Standard Time Delay Settings

Earth fault relays come with adjustable time delays. Typical ranges are:

- Short Delay: 0.2 – 0.5 seconds, suitable for high fault currents

- Medium Delay: 0.5 – 2 seconds, for general system protection

- Long Delay: 2 – 5 seconds, for motors or transformers with high inrush currents

The exact time delay depends on system design, load characteristics, and protection coordination.

Formula for Earth Fault Relay Time Delay Setting

Most earth fault relays operate on an inverse time characteristic, meaning the higher the fault current, the faster the relay trips. A common formula is:

T = k × (If / Ir)^n

Where:

- T = Time delay in seconds

- If = Fault current

- Ir = Relay rated current

- k = Relay constant

- n = Characteristic exponent, usually between 0.02 and 0.2

This formula ensures the relay responds faster to high fault currents while delaying action for smaller currents, preventing unnecessary trips.

Find out more about transformer differential protection

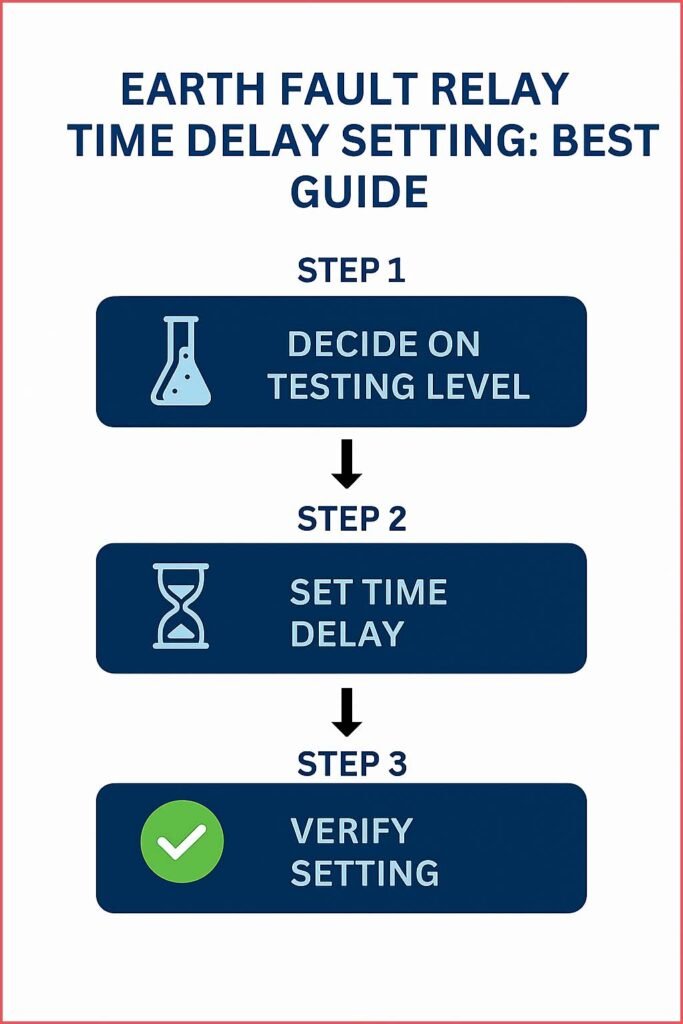

Steps to Set Earth Fault Relay Time Delay Settings

- Determine the system fault current and relay rating.

- Analyze load characteristics and inrush currents.

- Check coordination with upstream and downstream protection devices.

- Choose the appropriate time delay range based on the above factors.

- Fine-tune the relay using testing equipment to ensure reliable operation.

Testing Earth Fault Relay Time Delay

Testing ensures the relay operates correctly and within the desired time frame. Common methods include:

- Secondary injection testing: Injecting a known current into the relay circuit.

- Primary injection testing: Testing the relay with actual system current.

- Simulation: Using digital relays to simulate faults and observe relay response.

| Testing Method | Purpose |

|---|---|

| Secondary Injection | Verifies relay settings without affecting the system |

| Primary Injection | Confirms relay performance under actual system conditions |

| Simulation | Checks coordination and time delay in digital relays |

Regular testing ensures that the relay performs accurately and protects the system efficiently.

Explore details on IEC Standard for Differential Protection

Common Mistakes in Setting Time Delay

Incorrect time delay settings can lead to serious problems:

- Too short delay: Causes false tripping due to inrush currents.

- Too long delay: May fail to protect equipment during actual faults.

- Ignoring coordination: Can lead to cascading trips in connected equipment.

Ensuring proper settings, regular testing, and coordination with other protective devices is key to system safety.

Conclusion

The earth fault relay time delay setting is a critical parameter in electrical protection. It balances fast fault detection with preventing unnecessary tripping. Correct time delay ensures the safety of equipment, stability of the electrical system, and reliability of operation. By understanding the factors that affect time delay, using formulas for calculation, and performing proper testing, engineers can optimize protection and prevent costly damage.

Know more about alternator protection scheme

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#EarthFaultRelay, #RelayTimeDelay, #ElectricalProtection, #RelaySettings, #PowerSystemProtection, #EarthFaultProtection, #ElectricalEngineering, #TimeDelayRelay, #RelayGuide, #CircuitProtection