IEC Standard for Cable Derating Factors – Complete Guide to Cable Sizing & Current Capacity

When designing electrical systems, engineers often focus on selecting the correct cable size based on current carrying capacity. However, real-world conditions are rarely ideal. Temperature, grouping, soil type, and installation method can all affect cable performance. This is where the IEC standard for cable derating factors becomes critical. It provides standardized correction factors to ensure that cables operate safely and efficiently even under non-standard conditions. Understanding this topic is essential for electrical engineers, installers, and anyone involved in cable selection and installation.

Table of Contents

What is the IEC Standard for Cable Derating Factors

The IEC standard for cable derating factors is defined primarily in IEC 60364 and IEC 60287. These standards outline how environmental and installation conditions influence a cable’s ability to carry current. The derating factor is a multiplier used to reduce the nominal current rating of a cable to suit actual site conditions.

In simple terms, a derating factor adjusts the theoretical ampacity of a cable to a practical, real-world value. For example, if a cable has a current rating of 100A under standard conditions and a derating factor of 0.8 applies due to high ambient temperature, the actual permissible current is 80A. This ensures the cable does not overheat or degrade prematurely.

Uncover insights on iec standard for lighting lux level

Why Derating Factors Are Important

Ignoring cable derating factors can lead to severe problems. Overheated cables lose insulation integrity, leading to faults, fire hazards, and power losses. Using derating factors ensures:

- Safe cable operation under all conditions

- Longer cable life and insulation durability

- Compliance with IEC and national wiring standards

- Reduced energy losses due to overheating

The IEC standard for cable derating factors provides globally accepted guidelines that help prevent undersized cable installations and associated risks.

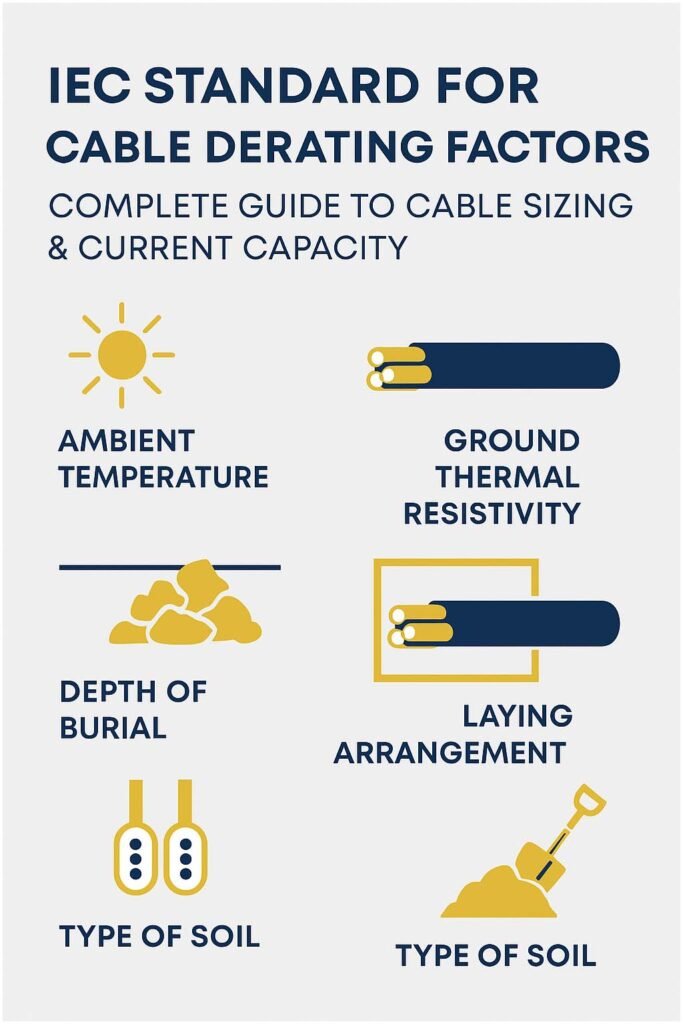

Parameters Affecting Cable Derating According to IEC Standards

The IEC standard identifies several conditions that affect cable performance. Each of these requires a specific correction or derating factor.

1. Ambient Temperature

Cable ratings are typically based on an ambient temperature of 30°C for air installation and 20°C for buried installations. If the actual ambient temperature is higher, the cable must be derated.

Table 1: Typical Ambient Temperature Derating Factors (Based on IEC 60364-5-52)

| Ambient Temperature (°C) | PVC Insulation | XLPE Insulation | EPR Insulation |

|---|---|---|---|

| 25 | 1.03 | 1.02 | 1.02 |

| 30 | 1.00 | 1.00 | 1.00 |

| 35 | 0.94 | 0.96 | 0.97 |

| 40 | 0.87 | 0.91 | 0.94 |

| 45 | 0.79 | 0.87 | 0.90 |

| 50 | 0.71 | 0.82 | 0.86 |

| 55 | 0.61 | 0.76 | 0.81 |

For example, if a PVC cable rated at 100A operates at 45°C, its derated current would be 100 × 0.79 = 79A.

Read in detail about iec 61439 busbar calculation

2. Grouping or Cable Bunching

When multiple cables are installed together, heat dissipation decreases. The IEC standard for cable derating factors provides grouping correction coefficients based on the number of cables and spacing between them.

Table 2: Typical Grouping Derating Factors (IEC 60364-5-52)

| Number of Cables in Group | Derating Factor |

|---|---|

| 1 | 1.00 |

| 2 | 0.80 |

| 3 | 0.70 |

| 4–6 | 0.65 |

| 7–9 | 0.60 |

| 10–12 | 0.55 |

| 13–20 | 0.50 |

For instance, a cable rated at 100A and installed with 5 other cables would be derated by 0.65, giving an effective current of 65A.

3. Installation Method

The way a cable is installed has a direct impact on heat dissipation. Cables installed in conduit, ducts, or underground have different derating needs compared to those laid in open air.

Table 3: Installation Method Derating Factors

| Installation Condition | Typical Derating Factor |

|---|---|

| In open air on perforated tray | 1.00 |

| In conduit on wall | 0.85 |

| Buried directly in soil | 0.90 |

| In thermal insulation | 0.70 |

| Enclosed trunking with other cables | 0.80 |

The IEC standard for cable derating factors (especially IEC 60287) provides mathematical models for determining temperature rise based on installation methods.

Dive deeper into instrument earthing iec standard

4. Soil Thermal Resistivity (for Buried Cables)

Cables buried in soil depend on the soil’s thermal properties to dissipate heat. The IEC assumes a standard soil resistivity of 1.2 K·m/W. When soil resistivity is higher, derating becomes necessary.

Table 4: Soil Thermal Resistivity Correction Factors (IEC 60287)

| Soil Thermal Resistivity (K·m/W) | Derating Factor |

|---|---|

| 0.8 | 1.06 |

| 1.0 | 1.00 |

| 1.2 | 0.96 |

| 1.5 | 0.89 |

| 2.0 | 0.80 |

A cable designed for standard conditions but buried in dry soil (2.0 K·m/W) will carry only 80% of its nominal rating.

5. Depth of Laying

The deeper a cable is buried, the higher the surrounding temperature and the lower the cooling efficiency. IEC standards provide correction factors for various burial depths.

Table 5: Burial Depth Correction Factors

| Burial Depth (m) | Derating Factor |

|---|---|

| 0.5 | 1.00 |

| 0.7 | 0.97 |

| 1.0 | 0.95 |

| 1.2 | 0.93 |

| 1.5 | 0.90 |

Understand better about nec 430.32

Combining Multiple Derating Factors

In real installations, multiple derating factors often apply simultaneously. The overall correction factor is the product of individual factors.

For example, assume:

- Ambient temperature = 45°C → 0.79

- Grouping (5 cables) → 0.65

- Installation in conduit → 0.85

Total Derating Factor = 0.79 × 0.65 × 0.85 = 0.436

If the nominal current rating is 100A, the derated current capacity = 100 × 0.436 = 43.6A.

This combined approach ensures accurate and safe current rating under complex site conditions.

How to Apply IEC Standard for Cable Derating Factors in Design

To apply these factors effectively, electrical engineers follow a systematic approach:

- Determine the nominal current rating of the selected cable from the manufacturer’s data or IEC 60364 tables.

- Identify environmental and installation parameters such as temperature, soil type, and grouping.

- Refer to IEC correction factor tables for each parameter.

- Multiply the nominal rating by the product of all applicable factors to get the derated current rating.

- Ensure that the derated rating still exceeds the circuit load current.

This process guarantees compliance with IEC and local wiring codes, such as BS 7671 in the UK or NEC in the US (when aligned with IEC methods).

Use our online tool electricity load calculator in kw for home

Real-World Example Using IEC Standard for Cable Derating Factors

Suppose a 3-core 16mm² XLPE cable has a base current rating of 90A under standard conditions. It is installed in a group of 4 cables, in a conduit on a wall, at 40°C ambient temperature.

- Temperature factor (40°C) = 0.91

- Grouping factor (4 cables) = 0.65

- Installation factor (conduit) = 0.85

Overall derating = 0.91 × 0.65 × 0.85 = 0.503

Derated current = 90 × 0.503 = 45.3A

This means the cable can safely carry only 45.3A in actual installation, not 90A. To carry the same current, a larger cable cross-section must be selected.

Compliance and Documentation

The IEC standard for cable derating factors emphasizes proper documentation of all assumptions and factors used during design. Engineers must record:

- Site temperature and soil data

- Installation configuration

- Derating calculations and tables referenced

Proper documentation supports safety audits, ensures long-term reliability, and helps during maintenance or system expansion.

Get complete information about iec standard for busbar sizing

Benefits of Following IEC Standard for Cable Derating Factors

Adhering to IEC guidelines brings several advantages:

- Accurate and safe cable sizing under all site conditions

- Reduced fire and fault risks due to overheating

- Extended service life of cables and equipment

- Easier compliance with international electrical standards

- Improved energy efficiency and lower operational costs

Related IEC Standards and References

The following IEC documents provide detailed methodologies and correction factors:

- IEC 60364-5-52: Electrical installations of buildings – Selection and erection of wiring systems

- IEC 60287: Electric cables – Calculation of current rating

- IEC 60853: Calculation of cyclic and emergency current ratings

These standards collectively form the global foundation for cable derating practices in electrical engineering.

Explore details on iec standard for underground cable laying

Conclusion

The IEC standard for cable derating factors is an essential reference for anyone involved in electrical design and installation. It ensures that cables are chosen with real-world conditions in mind rather than ideal laboratory assumptions. By applying derating factors for temperature, grouping, soil resistivity, and installation method, engineers can maintain safety, efficiency, and compliance with international standards.

A properly derated cable system not only prevents overheating and failures but also enhances the reliability of the entire electrical network. Following the IEC standard for cable derating factors is not just about meeting regulations—it’s about designing for safety, longevity, and performance.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#IECStandard, #CableDeratingFactors, #ElectricalEngineering, #CableSizing, #IECStandards, #ElectricalSafety, #PowerCables, #CurrentCarryingCapacity, #DeratingCalculation, #CableTemperature, #VoltageDrop, #IEC60287, #EngineeringStandards, #ElectricalDesign, #IndustrialWiring