Generator Sizing Calculator for Pumps

When choosing a generator for a pump, one size does not fit all. You need to know the correct generator size to avoid failures, overloads, or energy waste. A generator sizing calculator for pumps is the most efficient tool to solve this problem. It simplifies the process by providing accurate power requirements based on pump type, motor rating, and starting conditions.

The goal is not just to run the pump. It is to do it reliably, efficiently, and safely. Choosing the wrong generator may result in damage to equipment, higher fuel costs, or even complete system failure. Let’s dive into how generator sizing for pumps works and why a calculator makes it easier.

Understanding Generator Sizing Calculator for Pumps

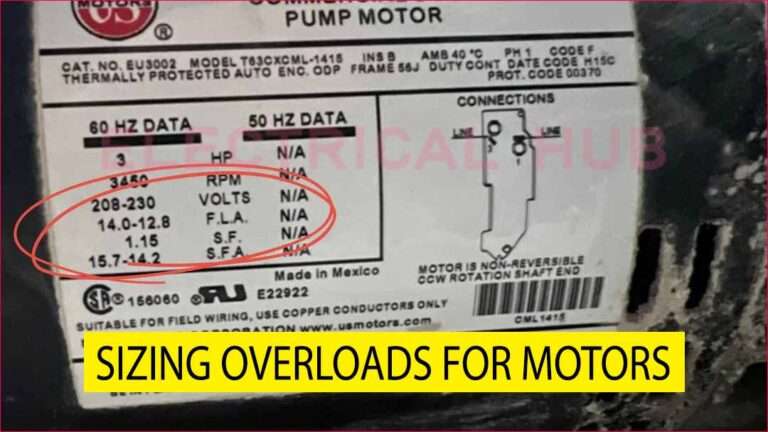

A generator sizing calculator for pumps takes into account several variables. These include pump horsepower (HP), voltage, power factor, starting method, and load type. Pumps have high starting currents. So the generator needs to supply both the starting and running current without dropping voltage or frequency.

Pumps usually fall into the category of inductive loads. These loads demand more power at startup. Inrush current can be 2 to 7 times the running current. A generator must be capable of handling this without performance dips.

There is also the matter of load type. Pumps may be centrifugal, positive displacement, or submersible. Each pump type has different torque characteristics. This directly affects the generator size required. Using a sizing calculator helps align these parameters with generator specifications.

Importance of Generator Sizing Calculator for Pumps

Without the right calculations, the generator may be under or oversized. Undersizing causes frequent tripping, overheating, or motor failure. Oversizing leads to fuel inefficiency and unnecessary cost. A generator sizing calculator for pumps removes guesswork and provides an ideal match.

Using a manual method involves multiple formulas, charts, and correction factors. But a sizing calculator uses built-in algorithms. These generate precise values based on real-world load profiles.

It saves time and improves accuracy. Also, modern calculators consider altitude, temperature, and derating factors automatically. That ensures the generator performs well in your actual operating conditions.

Factors Considered in Generator Sizing Calculator for Pumps

A generator sizing calculator for pumps considers several technical inputs:

- Pump type (centrifugal, positive displacement, submersible)

- Motor horsepower or kilowatt rating

- Motor voltage (single-phase or three-phase)

- Starting method (DOL, star-delta, soft start, VFD)

- Power factor (typically 0.8 for motors)

- Motor efficiency

- Altitude and ambient temperature

- Required runtime and load step changes

Let’s break these down with an example to better understand the process.

Generator Sizing Calculator for Pumps – Technical Example

Imagine you have a 10 HP centrifugal pump running on a 3-phase 400V motor with DOL (Direct On Line) start. Here’s how the sizing calculator works step by step:

| Parameter | Value |

|---|---|

| Motor Type | Induction |

| Motor HP | 10 HP |

| Motor Voltage | 400 V (3-phase) |

| Efficiency | 90% |

| Power Factor | 0.8 |

| Starting Method | DOL |

| Starting Current Multiplier | 6 x FLC (typical) |

Step 1: Convert HP to kW

1 HP = 0.746 kW

So, 10 HP = 7.46 kW

Step 2: Calculate Full Load Current (FLC)

Using the formula:

FLC = (kW × 1000) / (√3 × V × PF × Efficiency)

Substitute the values:

FLC = (7.46 × 1000) / (1.732 × 400 × 0.8 × 0.9)

FLC ≈ 15 Amps

Step 3: Estimate Starting Current

For DOL start, starting current is 6x FLC:

Starting Current ≈ 15 × 6 = 90 Amps

Step 4: Choose Generator Size

The generator must handle this starting surge. Most calculators add a 250% buffer for starting current. In this case, the recommended generator is around 20 to 25 kVA. This covers the inrush current and ensures stable operation.

How Generator Sizing Calculator for Pumps Helps Engineers

The calculator speeds up the design process. For field engineers, it provides quick results on-site. It eliminates manual error and ensures compliance with safety margins.

Moreover, some advanced calculators can generate sizing reports. These are useful for project approvals or procurement. They may also suggest generator brands or models that match your load profile.

Additionally, calculators can simulate multiple pump loads. This is useful for irrigation systems, fire pumps, or industrial processes with multiple stages.

Generator Sizing Calculator for Pumps in Variable Speed Applications

Modern pump systems often use Variable Frequency Drives (VFDs). A generator sizing calculator for pumps with VFD support is crucial. VFDs reduce starting current but can cause harmonic distortion. This affects generator waveform stability.

The calculator compensates for VFD losses and includes harmonic correction. This ensures clean power delivery to the pump. It also prevents generator hunting or de-rating issues.

Some calculators even allow the user to input harmonic levels. This helps in selecting compatible generators with proper AVR (Automatic Voltage Regulation) and frequency stability.

Generator Sizing Calculator for Pumps in Rural Areas

In rural or remote areas, diesel generators are widely used for pumps. Power grids may be unstable or unavailable. A generator sizing calculator for pumps makes sizing easier for such locations.

For instance, farmers use submersible pumps for irrigation. The calculator ensures the generator can handle daily cycles, long operating hours, and local voltage drops. It also helps choose fuel-efficient models that reduce long-term costs.

If multiple pumps operate together, the calculator can compute the cumulative demand. It also factors in staggered starts to minimize generator overload during peak usage.

Generator Sizing Calculator for Pumps and Environmental Conditions

The operating environment affects generator performance. High altitudes reduce air density, which limits engine power. Hot climates increase cooling demand. A generator sizing calculator for pumps automatically adjusts for these conditions.

For example, at 2000 meters elevation and 40°C, a generator may lose 10–15% of its rated output. The calculator factors this in and recommends a higher-rated generator accordingly.

This avoids undersized selections and prolongs equipment life. Most manual methods overlook these important details.

Generator Sizing Calculator for Pumps with Fuel Type Considerations

Depending on the fuel type—diesel, natural gas, or petrol—the generator’s performance changes. Diesel generators are popular for heavy-duty pump applications. Gas-powered ones are more suitable for lighter loads or standby systems.

A good generator sizing calculator for pumps will let you choose the fuel type. It then adjusts the recommended size based on fuel efficiency, start-up characteristics, and available power output.

This makes it easy to select not just the right size but the right type of generator for the job.

Online Tools Offering Generator Sizing Calculator for Pumps

Several manufacturers and service providers offer online tools. These include Cummins, CAT, Generac, and Kohler. Each tool requires simple inputs and delivers reliable results within seconds.

They often include built-in safety margins, regional standards, and even generator model suggestions. For engineers, this means faster procurement and deployment.

Some calculators also support multi-language input, downloadable reports, and integration with design software like AutoCAD or Revit.

Conclusion on Generator Sizing Calculator for Pumps

A generator sizing calculator for pumps is not just a convenience—it’s a necessity. With growing demand for energy-efficient systems, precision sizing is key. It ensures performance, safety, and cost-effectiveness.

Whether you’re managing irrigation, HVAC, water treatment, or firefighting systems, the right generator matters. Use a calculator to eliminate guesswork and choose wisely.

By understanding pump characteristics, electrical loads, and startup conditions, the sizing calculator simplifies complex decisions. It’s the smart way to select a generator that meets your pumping needs, now and into the future.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#GeneratorSizing, #PumpPowerCalculator, #GeneratorForPumps, #SizingCalculator, #ElectricalEngineering, #DieselGeneratorSizing, #PumpMotorLoad, #BackupPower, #GeneratorLoadCalculation, #RightSizeGenerator, #IndustrialPumps, #MotorStartingCurrent, #PowerNeeds, #EngineeringTools, #EnergyEfficiency