480/277 V Wiring Diagram in Industrial Setups: Complete Guide for Safe Power Distribution

Understanding a 480/277 V wiring diagram is essential for anyone involved in industrial electrical design, facility upgrades, or troubleshooting. This voltage configuration is common in commercial buildings, factories, and large warehouses. It supports heavy equipment loads while also providing efficient single-phase power for lighting systems. When electricians and engineers know how the system is wired, they can plan distribution, reduce faults, and maintain compliance with electrical codes.

Table of Contents

What a 480/277 V System Means

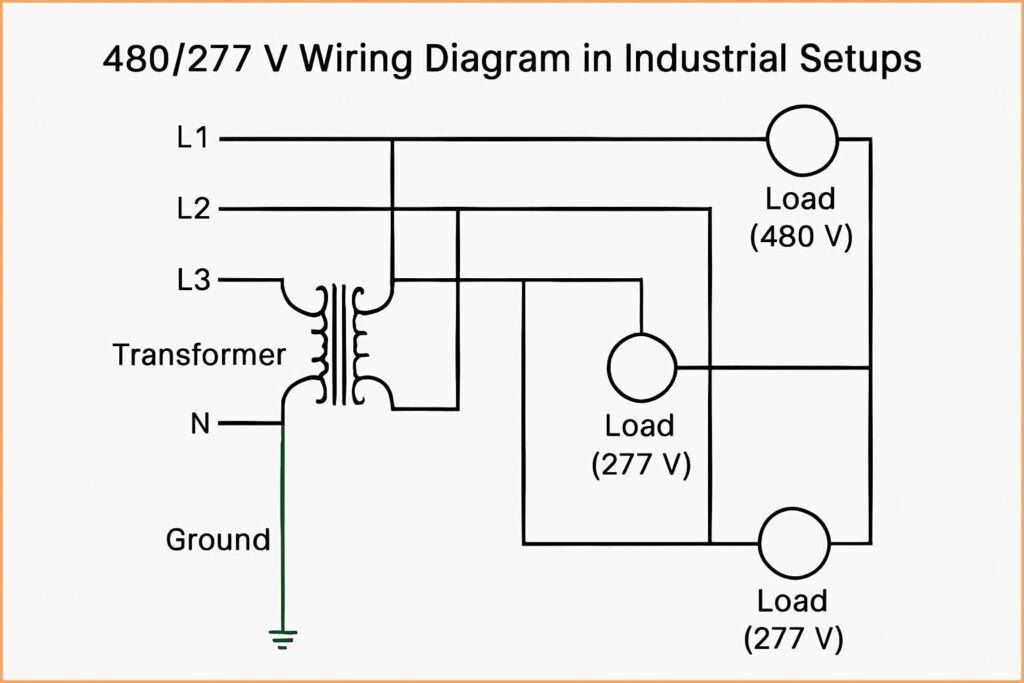

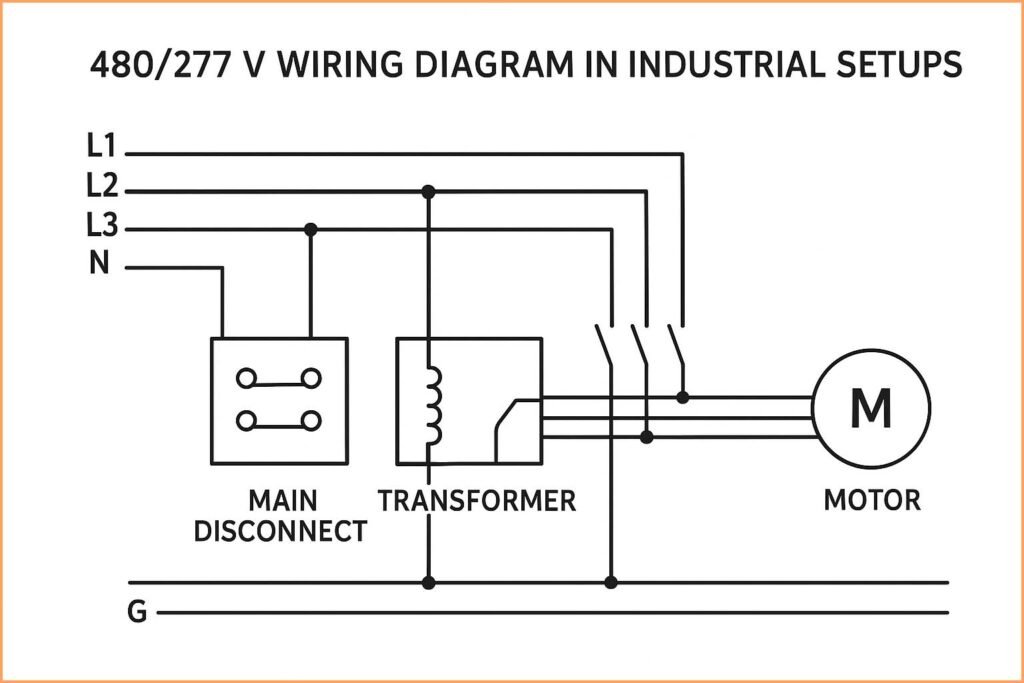

A 480/277 V system is a three-phase configuration. It delivers 480 volts line-to-line and 277 volts line-to-neutral. It is often built around a wye (Y) transformer. The wye connection allows the neutral point to serve lighting circuits at 277 volts, while the phase-to-phase voltage powers motors and machinery at 480 volts.

In industrial environments, this setup has become a standard. It reduces current draw, supports long cable runs, and keeps energy losses low. It also allows the facility to separate lighting loads from heavy mechanical loads using the same transformer. Learn more about is 277 high voltage

Key Components in a 480/277 V Wiring Diagram

A typical wiring diagram for this system includes several major components. These elements form the backbone of industrial electrical distribution.

Transformer

Most diagrams show a three-phase step-down transformer from medium voltage. The secondary winding is drawn in a wye configuration. The neutral point is grounded. The diagram labels X1, X2, and X3 as the phase connections, with X0 as the neutral.

Main Switchgear

The switchgear manages fault protection and load distribution. Circuit breakers rated for 480 V are placed here. The wiring diagram illustrates how feeders branch to lighting panels, motor control centers, and process equipment. Discover everything about Parallel Run for 300Amp 480/277

Distribution Panels

You will see two major types of panels:

- 480 V panels for motors, HVAC systems, pumps, and industrial drives

- 277 V lighting panels for fluorescent and LED lighting circuits

Grounding System

A proper grounding and bonding system is shown in every compliant wiring diagram. It prevents overvoltages during faults and stabilizes voltage to earth. The neutral is grounded at one point only.

Conduit and Conductors

The wiring diagram outlines conductor sizes, insulation types, and conduit routing. Industrial spaces usually rely on THHN or XHHW wire. Conductors must be rated for 600 V to support all circuit conditions. Find out more about what is 277 voltage

How 480/277 V Wiring Diagrams Are Structured

A wiring diagram is different from a schematic. It shows physical wiring and actual conductor paths. It may include line symbols, termination points, breaker ratings, equipment outlines, and grounding paths.

Here is a quick reference table that summarizes how voltages appear in the diagram:

| Measurement Type | Voltage Value | Purpose |

|---|---|---|

| Line-to-Line | 480 V | Motors, large equipment, industrial loads |

| Line-to-Neutral | 277 V | Lighting circuits, single-phase loads |

| Neutral-to-Ground | 0 V | Ground reference |

| Phase-to-Ground | 277 V | Safety and fault return path |

The diagram usually starts at the transformer’s secondary terminals. From there, it shows the main breaker, feeders, panels, branch circuits, and load symbols. Each conductor is marked with color codes, often:

- Brown, orange, yellow for 480 V phases

- Gray for neutral at 277 V

- Green or green/yellow for ground

These color codes may vary by region, so local codes must always be checked. Explore details on iec and ieee standards

Why Industrial Facilities Use 480/277 V Systems

The 480/277 V configuration is popular because it offers high efficiency. Motors run better with higher voltage. Lighting systems benefit from 277 V circuits because they allow long runs without heavy wire sizes. Facilities also reduce transformer losses by using a single three-phase transformer for mixed loads.

Another advantage is cost control. Smaller conductors, smaller breakers, and lower current levels reduce installation cost. Facilities with large HVAC loads and process equipment prefer this voltage because it improves overall operational stability.

Know more about load factor calculation formula

Reading a 480/277 V Wiring Diagram Step by Step

Step 1: Identify the Power Source

Locate the transformer symbol first. Note its primary and secondary connections. Confirm the secondary is configured in a wye. Look for X0 to verify the neutral.

Step 2: Follow the Feeder Paths

Trace the conductors leaving the transformer. They enter the switchgear. The diagram labels each breaker size, trip rating, and feeder cable type.

Step 3: Understand Panel Distribution

Lighting panels fed at 277 V will have a neutral conductor. Motor panels at 480 V will not require neutral. Each panel is shown with branch circuits, wire type, and breaker ratings.

Step 4: Check Load Connections

Motors appear as three-phase load symbols. Lighting loads appear as single-phase. Control circuits often use step-down transformers for 120 V control power. These secondary control voltages are shown within the same wiring diagram to provide clarity.

Learn more about capacity factor formula

Step 5: Review Grounding and Bonding

A complete wiring diagram will show:

- Equipment grounding conductor

- Grounding electrode conductor

- Main bonding jumper

- Neutral-to-ground connection at service entrance

Industrial safety depends on proper grounding.

Common Applications in Industrial Facilities

A wiring diagram for a 480/277 V system is used in several industrial applications, including:

- Manufacturing lines with multiple motors

- Industrial HVAC systems

- Warehouse LED lighting circuits

- Pumping stations

- Conveyor belts and automated machinery

- Data centers and commercial buildings

These environments depend on stable three-phase power for continuous operation. Get complete information about power factor correction calculations

Best Practices When Creating or Using a 480/277 V Wiring Diagram

A well-designed wiring diagram follows electrical codes and safety requirements. Here are best practices that professionals follow:

Keep Diagrams Updated

When equipment is added or removed, the wiring diagram must be revised. Accurate documentation reduces troubleshooting time.

Label All Conductors Clearly

Labels should match panel directories and equipment naming conventions. This prevents confusion during maintenance.

Easily calculate kva for house using our online tool for free

Include Equipment Ratings

Voltage, amperage, and trip ratings help technicians choose correct replacement parts.

Provide Clear Grounding Paths

Grounding conductors should be shown without ambiguity. A clear grounding layout reduces arc-flash risks.

Use Standard Electrical Symbols

Using recognized symbols improves communication between engineers, contractors, and inspectors.

Troubleshooting with a 480/277 V Wiring Diagram

A detailed wiring diagram helps technicians solve problems faster. When motors fail, lighting circuits flicker, or breakers trip, the diagram becomes the primary point of reference. Technicians trace the circuit, check voltage levels, inspect terminations, and confirm grounding continuity using the diagram.

Troubleshooting is easier when diagrams include:

- Voltage references

- Panel schedules

- Conductor sizes

- Terminal numbers

These details shorten downtime in industrial facilities.

Dive deeper into off grid solar system design

Final Thoughts

A 480/277 V wiring diagram is a fundamental tool in industrial electrical design and maintenance. It guides electricians, engineers, and plant operators in understanding how power flows through a building. It also provides the clarity needed for installation, repair, and inspection work. When diagrams are kept accurate, facilities can operate more safely and efficiently.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#480V, #277V, #IndustrialWiring, #ElectricalDesign, #WiringDiagram, #IndustrialPower, #ElectricalEngineering, #PowerDistribution, #FacilityMaintenance, #ElectricalSystems