Wire Size Chart for Amps: Proven Smart Guide That Boosts Power Safety

Choosing the correct electrical wire is one of the most important steps in any electrical project. A wrong selection can cause overheating, voltage drop, poor performance, and even fire hazards. This is where a wire size chart for amps becomes essential. It helps electricians, engineers, and DIY users match current load with the correct wire gauge for safe and efficient operation.

Table of Contents

In this guide, you will learn how wire sizing works, how amperage affects conductor selection, and how to use charts confidently in real-world applications. This article is written in a practical, easy-to-read style so you can apply the knowledge immediately.

Use this tool if you are trying to calculate cable size for underground cables. Try here Underground Cable Size Calculator – Find Correct Wire Size for Long Distance Runs

Why Wire Size Matters in Electrical Systems

Wire size directly affects how much current a conductor can safely carry. When current flows through a wire, resistance produces heat. If the wire is too small for the current load, excessive heat builds up and damages insulation. This can shorten equipment life and increase safety risks. A proper wire size chart for amps ensures the conductor stays within its safe temperature limit under continuous load.

Another key factor is voltage drop. Longer wire runs increase resistance, causing voltage loss at the load end. Correct wire sizing reduces voltage drop and keeps appliances running efficiently. This is especially important for motors, HVAC systems, and industrial equipment.

Understanding Amps, Wire Gauge, and AWG System

Amperage, or amps, measures the amount of electrical current flowing through a conductor. Wire gauge defines the physical thickness of the wire. In most regions, the American Wire Gauge system is used. A lower AWG number means a thicker wire with higher current capacity.

For example, a 10 AWG wire can carry more current than a 14 AWG wire. This relationship is the foundation of any wire size chart for amps. Knowing how gauge and current relate helps you make safer choices for residential, commercial, and automotive wiring.

Take a look at this tool for a smarter way to handle feeder wire sizing Feeder Wire Size Calculator – Accurate Guide for Electricians and Homeowners

Standard Wire Size Chart for Amps

The table below shows common copper wire sizes and their typical amp ratings under standard conditions. These values assume copper conductors with standard insulation and normal ambient temperature.

| Wire Gauge (AWG) | Max Amps (Approx) | Common Applications |

|---|---|---|

| 14 AWG | 15 Amps | Lighting circuits, outlets |

| 12 AWG | 20 Amps | Kitchen outlets, small appliances |

| 10 AWG | 30 Amps | Water heaters, dryers |

| 8 AWG | 40 Amps | Ranges, AC units |

| 6 AWG | 55 Amps | Subpanels, feeders |

| 4 AWG | 70 Amps | Large motors, service feeders |

| 2 AWG | 95 Amps | Industrial equipment |

This wire size chart for amps is widely used as a reference, but it should always be adjusted for specific conditions such as temperature, insulation type, and installation method.

Discover how this tool works and why it’s worth using NEC Wire Size Calculator – Voltage Drop Compliant Sizing for 120V & 240V Circuits

Aluminum vs Copper Wire Ampacity

Copper wire is the most commonly used conductor due to its high conductivity and durability. Aluminum wire is lighter and less expensive but requires a larger size to carry the same current. When using aluminum conductors, always refer to an aluminum-specific wire size chart for amps.

| Material | AWG Size | Typical Amp Rating |

|---|---|---|

| Copper | 8 AWG | 40 Amps |

| Aluminum | 6 AWG | 40 Amps |

Using aluminum wire without upsizing can lead to overheating. Always check terminal compatibility and follow electrical code guidelines.

Factors That Affect Wire Amp Rating

Several real-world factors influence how much current a wire can safely handle. Understanding these helps you use a wire size chart for amps more accurately.

Temperature plays a major role. Higher ambient temperatures reduce a wire’s ability to dissipate heat. Bundling multiple wires together also increases heat buildup. Insulation type matters as well, since some insulation materials tolerate higher temperatures than others.

Installation method is another consideration. Wires run inside conduit have less airflow compared to open wiring. This often requires selecting a larger gauge than what a basic chart suggests.

This tool is perfect for achieving better results in solar system design. Try here Wire Size Calculator for Solar Panels – Avoid Power Loss in Off-Grid and Hybrid Systems

Wire Size Chart for Amps with Voltage Drop Consideration

Voltage drop becomes critical for long cable runs. A general rule is to keep voltage drop below 3 percent for branch circuits. The table below shows how wire size may increase as distance grows.

| Current Load | Distance | Recommended Wire Size |

|---|---|---|

| 15 Amps | 50 ft | 14 AWG |

| 15 Amps | 100 ft | 12 AWG |

| 20 Amps | 50 ft | 12 AWG |

| 20 Amps | 100 ft | 10 AWG |

| 30 Amps | 50 ft | 10 AWG |

| 30 Amps | 100 ft | 8 AWG |

Using this approach ensures stable voltage at the load and improves equipment efficiency.

Residential Wiring Applications

In homes, correct wire sizing ensures safety and compliance with electrical codes. Lighting circuits typically use 14 AWG wire on 15 amp breakers. Kitchen and bathroom outlets usually require 12 AWG wire due to higher current demand.

Try this tool out to save time and effort for easy conversions Amps to Wire Size Calculator – Choose the Right Cable for 10A, 20A, 40A Loads

Appliances like electric ovens, water heaters, and air conditioners draw significant current. In these cases, consulting a wire size chart for amps helps avoid undersized conductors and nuisance breaker trips.

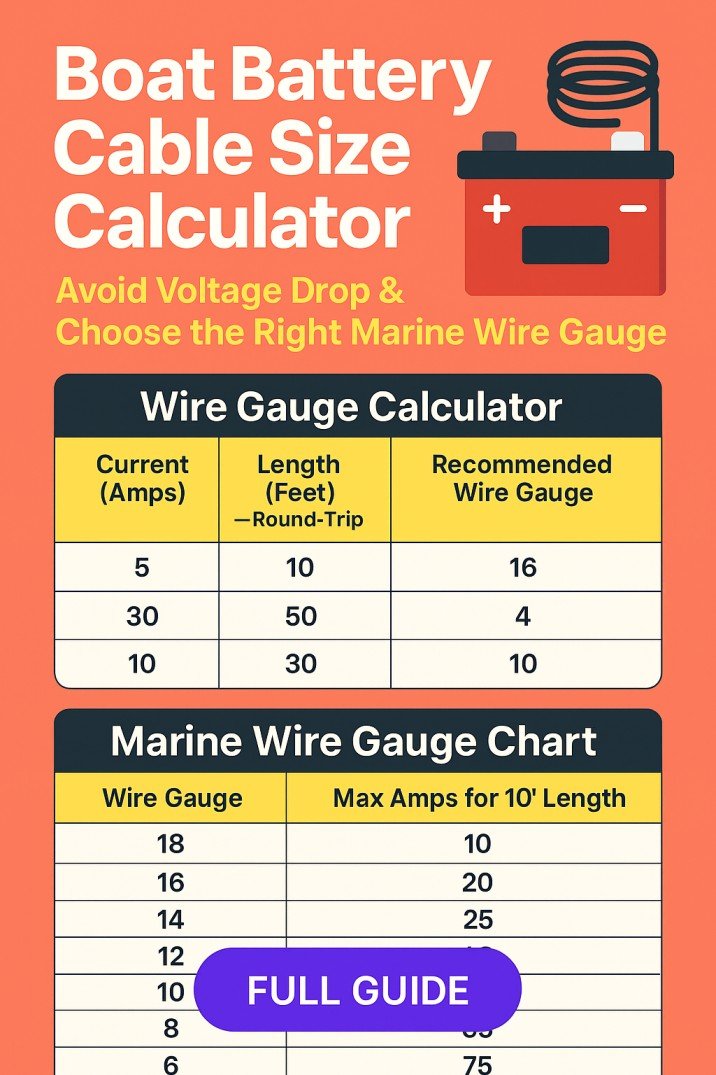

Automotive and DC Wiring Considerations

Automotive and solar systems often operate on low voltage but high current. This makes proper wire sizing even more important. A small voltage drop can significantly affect performance.

DC systems typically require thicker wires than AC systems for the same power level. Always select wire based on current draw, cable length, and duty cycle. Referring to a wire size chart for amps designed for DC use improves reliability and reduces power loss.

Industrial and Commercial Wiring Needs

Industrial environments involve motors, pumps, and heavy machinery. These loads often have high starting currents. Wires must be sized to handle both running and inrush current safely.

In commercial buildings, multiple circuits run together in trays or conduits. Derating factors apply in such cases. Using a wire size chart for amps along with local electrical codes ensures long-term safety and system stability.

Try this tool out to save time and effort for easy conversions Amps to Wire Size Calculator – Choose the Right Cable for 10A, 20A, 40A Loads

Common Wire Sizing Mistakes to Avoid

One common mistake is choosing wire size based only on breaker rating. While breakers protect circuits, wires must also handle continuous loads. Another error is ignoring voltage drop over long distances.

Some users assume thicker wire is always better, but oversized wire can increase cost and installation difficulty. The goal is correct sizing, not excessive sizing. A reliable wire size chart for amps helps strike the right balance.

How to Choose the Right Wire Size Step by Step

Start by determining the current load in amps. Measure or calculate the expected load accurately. Next, identify the circuit length and operating voltage. Check whether the environment has high temperature or bundled cables.

Then, consult a trusted wire size chart for amps and select the gauge that meets all conditions. Finally, verify compliance with local electrical codes before installation.

Final Thoughts on Safe and Efficient Wire Selection

Correct wire sizing is not just a technical requirement. It is a safety practice that protects property and lives. By understanding how amperage, wire gauge, material, and distance interact, you can design electrical systems that perform reliably for years.

We recommend this tool for anyone struggling with the sizing of subpanels. Try here Wire Size Calculator for Subpanels and Feeders – NEC Guidelines Included

A well-used wire size chart for amps simplifies decision-making and reduces costly mistakes. Whether you are wiring a home, upgrading equipment, or planning an industrial installation, using the right chart ensures efficiency, compliance, and peace of mind.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#WireSizeChartForAmps, #ElectricalWiringGuide, #AmpWireSizing, #CableSizeChart, #ElectricalSafety, #PowerDistribution, #HomeWiring, #IndustrialElectrical, #ElectricianTips, #VoltageDrop