Time Delay Relay Selection Guide: How to Choose the Perfect Relay for Your System

Selecting the right time delay relay is a critical step in designing any electrical or automation system. A well-chosen relay ensures operational efficiency, system protection, and long-term reliability. However, with so many types, functions, and specifications available, engineers, technicians, and system designers often face challenges in making the right choice. This guide provides a comprehensive approach to time delay relay selection, covering types, features, applications, and practical tips to make an informed decision.

Table of Contents

Understanding Time Delay Relays

A time delay relay is an electromechanical or solid-state device that controls the timing of electrical circuits. Unlike ordinary relays that operate immediately when voltage is applied, a time delay relay introduces a controlled delay before switching its contacts. This feature is vital in applications such as motor control, heating systems, conveyor belts, and lighting systems, where precise timing improves performance and safety.

Know more about How Does Earth Fault Relay Protect Electrical Circuits? Complete Guide to Ground Fault Protection

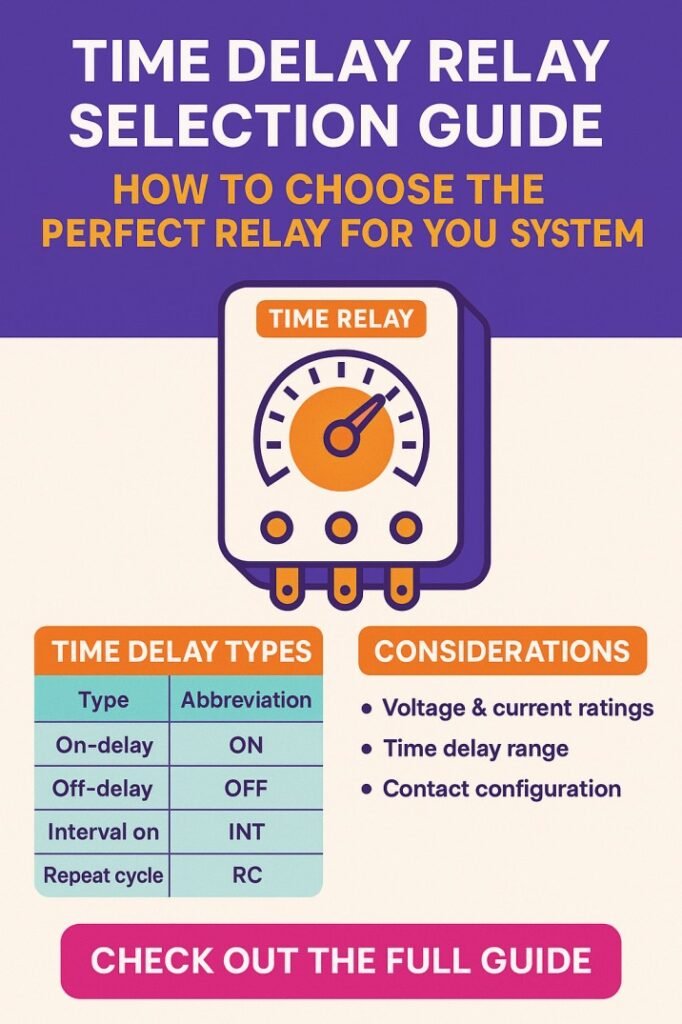

Time delay relays can be broadly classified based on their operation:

- ON-delay relay: Activates its contacts after a preset time once power is applied.

- OFF-delay relay: Maintains the contacts energized for a set period after the input signal is removed.

- Interval or one-shot relay: Energizes the load for a fixed time interval regardless of the input signal duration.

Understanding these basic types is the first step in accurate time delay relay selection.

Key Factors in Time Delay Relay Selection

Choosing the right relay involves several considerations that ensure compatibility and reliability. The following factors are crucial in time delay relay selection:

- Voltage and Current Rating: Ensure the relay matches the supply voltage and can handle the load current.

- Timing Range: Select a relay with a timing range suitable for your application, whether in milliseconds, seconds, or minutes.

- Contact Configuration: Determine if you need normally open (NO), normally closed (NC), or changeover contacts.

- Environmental Conditions: Consider temperature, humidity, vibration, and dust, which may affect relay performance.

- Reset and Repeatability: Verify if the relay offers automatic or manual reset and consistent timing accuracy.

- Mounting Type: Choose between panel mount, DIN rail, or socket mount based on installation convenience.

Know more about Earth Fault Relay Testing Procedure

Common Applications of Time Delay Relays

Time delay relays are used in a variety of industrial, commercial, and residential applications. Understanding these applications helps in narrowing down the right type of relay:

- Motor Protection: Delays in starting or stopping motors prevent mechanical stress.

- Lighting Control: Automatically switches lights on or off after a set time.

- Industrial Automation: Synchronizes machines or production processes with precise timing.

- HVAC Systems: Controls compressors, fans, and pumps with accurate delays.

- Safety Circuits: Ensures machinery operates only after all conditions are safe.

Types of Time Delay Relays

Time delay relays vary based on their operating mechanism, which influences their performance and suitability for different applications. The main types include:

| Relay Type | Operation | Ideal Applications | Advantages | Limitations |

|---|---|---|---|---|

| Electromechanical Relay | Uses coil and mechanical contacts | Motors, lighting, industrial machinery | Durable, simple, cost-effective | Limited speed, susceptible to mechanical wear |

| Solid-State Relay (SSR) | Uses semiconductor components | Automation, PLC systems | Fast, silent, no mechanical wear | Higher cost, requires heat dissipation |

| Multifunction Relay | Combines multiple timing functions | Complex industrial processes | Flexible, reduces number of relays | More expensive, complex wiring |

| Digital Programmable Relay | Microcontroller-based, programmable | Advanced automation, timed sequences | Highly accurate, easy programming | Requires power supply, higher cost |

Know more about Earth Fault Relay Sensitivity Setting: 5 Proven Tips for Better Protection

How to Calculate Timing Requirements

Before selecting a relay, understanding your system’s timing needs is crucial. Consider the following steps:

- Determine the load type (resistive, inductive, or capacitive).

- Identify the desired delay period for starting or stopping the load.

- Check if time variability or precision is required.

- Factor in safety margins to prevent operational failures.

For instance, if a motor requires a start delay of 5 seconds to avoid mechanical shock, choosing a relay with a timing range of 0–10 seconds provides flexibility and safety.

Selecting the Right Contact Rating

Contact ratings define the maximum load the relay can switch without damage. Improper ratings can lead to overheating, welding of contacts, or premature failure. Consider these guidelines:

Know more about Difference Between Relay and Contactor: 7 Powerful Reasons This Guide Makes It Easy

- Match the relay voltage rating with the supply voltage.

- Ensure current rating exceeds the inrush current of inductive loads.

- For AC loads, confirm the voltage and current ratings for both resistive and inductive operations.

| Load Type | Typical Relay Requirement | Notes |

|---|---|---|

| Resistive | Equal to operating current | Simple calculation |

| Inductive | 1.5 to 2× operating current | Accounts for inrush |

| Capacitive | 2× or more | High surge current |

Mounting and Wiring Considerations

Proper installation is essential for reliable performance. Factors to consider:

- Mounting type: DIN rail or panel mount for easy replacement and maintenance.

- Wiring: Use correct gauge wires to prevent voltage drops.

- Environment: Ensure protection against moisture, dust, and vibration.

- Labeling: Clearly mark relay functions to prevent errors during troubleshooting.

Read in detail about types of transformer protection relays

Practical Tips for Reliable Time Delay Relay Selection

- Always consult the manufacturer’s datasheet for exact specifications.

- Use a relay with slightly higher voltage and current ratings for safety margin.

- Consider solid-state relays for high-speed applications requiring silent operation.

- Choose a multifunction relay when multiple timing functions are needed.

- Test the relay under real operating conditions before final deployment.

Common Mistakes to Avoid

Even experienced engineers can make mistakes when selecting time delay relays. Avoid these pitfalls:

- Using a relay with inadequate current rating for inductive loads.

- Selecting a relay with a timing range incompatible with system needs.

- Ignoring environmental factors that affect relay lifespan.

- Overcomplicating the system with multiple relays instead of a multifunction or programmable relay.

- Neglecting manufacturer specifications and standards compliance.

Find out more about transformer differential protection

Advantages of Correct Time Delay Relay Selection

A properly selected time delay relay ensures:

- Enhanced system reliability and longevity.

- Reduced wear and tear on mechanical components.

- Precise control over timing operations.

- Energy savings and operational efficiency.

- Simplified maintenance and troubleshooting.

Conclusion

Effective time delay relay selection is not just about choosing a device; it is about understanding your system, its timing requirements, load characteristics, and environmental conditions. By considering relay type, voltage and current ratings, timing range, contact configuration, and installation requirements, engineers can ensure optimal performance, safety, and longevity of their systems. Using this guide, professionals can make informed decisions and avoid common pitfalls, ultimately enhancing system efficiency and reliability.

Learn more about types of generator protection relays

Selecting the perfect relay for your system requires a balance of technical knowledge and practical insight. Always prioritize reliability, precise timing, and compatibility to ensure smooth operation.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#TimeDelayRelay, #RelaySelectionGuide, #ElectricalEngineering, #AutomationControl, #IndustrialRelays, #RelayTips, #ElectricalDesign, #ControlPanel, #EngineeringGuide, #RelayBasics