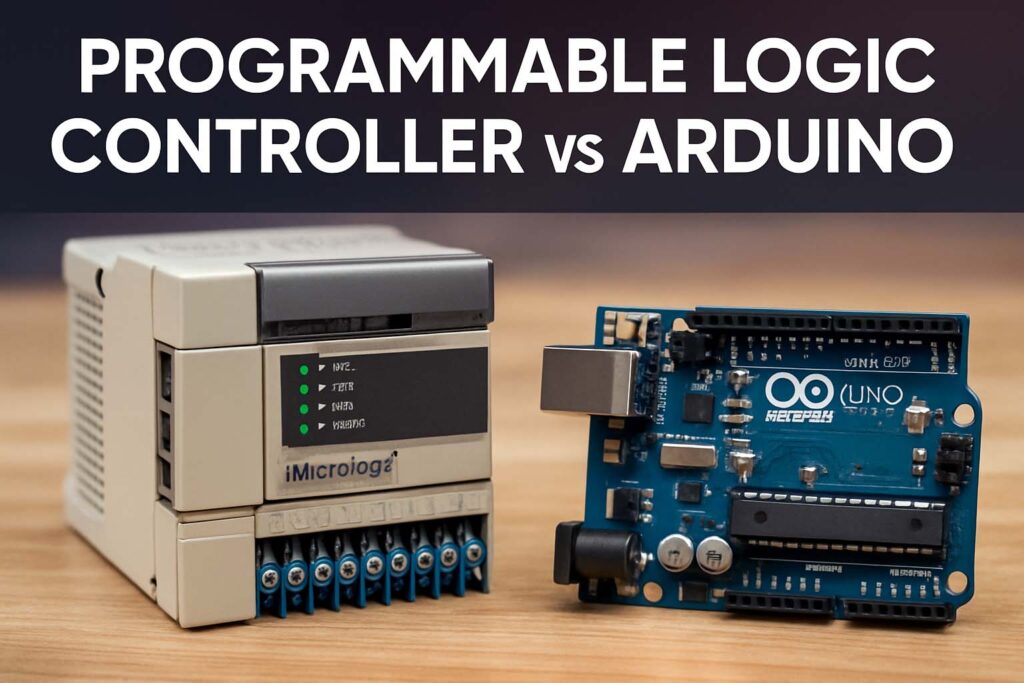

Programmable Logic Controller vs Arduino

In the world of automation and embedded systems, Programmable Logic Controller vs Arduino is a common comparison. Both are used to control machines and processes, but they are very different in design, purpose, and performance.

Whether you’re building an industrial automation system or working on a home automation project, understanding the difference between PLC and Arduino is crucial. This article explores the strengths, weaknesses, and use cases of each to help you make an informed decision.

What is a Programmable Logic Controller?

A Programmable Logic Controller (PLC) is a rugged industrial computer used to control manufacturing processes. PLCs are designed to operate in harsh environments, including high temperatures, moisture, dust, and electrical noise. They are widely used in industries like oil and gas, water treatment, power plants, packaging, and manufacturing.

PLCs use ladder logic or function block diagrams for programming. These programming methods are graphical and easy to understand for electricians and automation engineers. They are built to run 24/7 with minimal downtime.

PLCs have built-in safety features, reliable I/O modules, and diagnostic tools. They are preferred in applications where system reliability and robustness are critical.

Know more about Siemens S7-1200 Programmable Logic Controller

What is Arduino?

Arduino is an open-source electronics platform based on easy-to-use hardware and software. It is highly popular among hobbyists, students, and developers for building DIY projects, prototypes, and educational tools. Arduino boards are microcontroller-based and use the Arduino IDE for programming in simplified C/C++.

Arduino is ideal for small-scale automation, sensors, robotics, and IoT devices. It is lightweight, affordable, and extremely flexible, but not designed for industrial applications. It lacks the industrial-grade safety, noise immunity, and fail-safe features that PLCs offer.

Now let’s explore the technical comparison of Programmable Logic Controller vs Arduino.

Know more about Introduction to Siemens Programmable Logic Controllers (PLC)

Technical Comparison: Programmable Logic Controller vs Arduino

Here’s a side-by-side comparison of both platforms in terms of important parameters:

| Feature | Programmable Logic Controller (PLC) | Arduino |

|---|---|---|

| Target Users | Industrial engineers, automation experts | Students, hobbyists, researchers |

| Environment | Industrial, harsh environments | Educational, prototyping, small-scale setups |

| Programming Language | Ladder Logic, FBD, Structured Text | Arduino C/C++ |

| Software Tools | Proprietary (Siemens TIA, RSLogix) | Open-source (Arduino IDE) |

| I/O Handling | Robust, isolated I/Os | Basic GPIO pins |

| Communication Protocols | Modbus, Profibus, Ethernet/IP | I2C, SPI, UART, Wi-Fi, BLE |

| Power Supply | 24V DC or 230V AC | 5V or 3.3V DC |

| Expandability | Through modules | Through shields and breakout boards |

| Real-Time Operation | Yes, deterministic timing | Limited real-time capabilities |

| Cost | High (hundreds to thousands of USD) | Low (under $50 for most boards) |

| Durability | High, shock and noise resistant | Low, not suited for rugged environments |

As shown in the table, Programmable Logic Controller vs Arduino differs not only in hardware but also in usage approach and intended application domain.

When to Use PLC?

Use a Programmable Logic Controller if you’re dealing with:

- Industrial machinery

- Safety-critical systems

- Long-running production processes

- Systems requiring hard real-time behavior

- Applications where downtime can cause major losses

PLCs are engineered for reliability. Once programmed, they can run for years without a reboot. For example, in a water treatment plant, the pumps, motors, and valves are often controlled by a PLC to ensure precise operation with little human interference.

Know more about How Difficult Is It to Learn Programmable Logic Controller (PLC)?

When to Use Arduino?

Choose Arduino if your application is:

- Educational or academic

- Small automation system

- IoT device

- Home automation

- Prototype or proof-of-concept

Arduino is excellent for experimenting, learning, or building smart devices. For example, a temperature-controlled fan, Bluetooth light switch, or a greenhouse monitoring system can all be built with Arduino easily and cost-effectively.

Key Differences in Programming: PLC vs Arduino

Another core difference in Programmable Logic Controller vs Arduino is the programming style and accessibility.

PLCs are mostly programmed using Ladder Logic or IEC 61131-3 compliant languages. These languages are easier to read for electrical engineers and are made to represent electrical diagrams. PLCs use professional software such as Siemens TIA Portal, Allen-Bradley RSLogix, or Schneider EcoStruxure.

Arduino is programmed in a simplified version of C/C++ using the Arduino IDE. The code is written in a linear, script-like structure. It is more flexible and gives low-level access to hardware, which is excellent for rapid development but requires more coding knowledge.

Know more about What is a Programmable Logic Controller (PLC) and How Does it Work?

Example: Turning on a Motor

In PLC Ladder Logic:

[Start Button] ----[ ]-----+----( )----[Motor Output]

|

[Stop Button ] ---[/]-----+

In Arduino Code:

int motorPin = 9;

void setup() {

pinMode(motorPin, OUTPUT);

}

void loop() {

digitalWrite(motorPin, HIGH);

delay(10000);

digitalWrite(motorPin, LOW);

delay(10000);

}

This simple example shows how differently the logic is represented in both systems.

Safety and Reliability Considerations

One of the most important areas in Programmable Logic Controller vs Arduino is system safety and reliability.

PLCs follow industrial safety norms. They often include watchdog timers, fail-safe I/Os, diagnostics, and redundancy. They are certified for use in mission-critical environments.

Arduino boards, on the other hand, do not include any such safety layers by default. If a code hangs or an error occurs, the system may crash silently. While this is acceptable for a home automation device, it is dangerous for an industrial system.

Know more about Top 10 Electric Motor Manufacturers in the World

Scalability and Maintenance

In terms of long-term use, PLCs have better scalability. You can add I/O modules, communication cards, and HMI panels with ease. PLC-based systems also come with structured documentation, version control, and professional support.

Arduino projects are often one-off or single-person efforts. While Arduino systems can be expanded using shields and libraries, scaling beyond a few devices becomes complex and fragile. Maintenance also becomes difficult due to lack of documentation and professional support.

Industrial Use Cases of PLC

Here are some common use cases of PLC:

- Conveyor belt automation

- Packaging lines

- SCADA integration for remote plant control

- Elevator control

- Smart grid automation

DIY and Educational Use Cases of Arduino

Arduino excels in:

- Weather stations

- Line-following robots

- Home automation (light control, door locking)

- Wireless sensor networks

- Smart plant watering systems

Final Verdict: Programmable Logic Controller vs Arduino

The answer to Programmable Logic Controller vs Arduino really depends on your application. If you need a reliable, industrial-grade solution that must run continuously in harsh environments, a PLC is the right choice. It offers safety, diagnostics, real-time performance, and long-term support.

If you’re learning about electronics, working on a prototype, or building a hobby project, Arduino is the better option. It is cheaper, easier to learn, and perfect for exploring the world of automation and embedded systems.

Both platforms serve different purposes. Rather than seeing them as rivals, it is better to see them as tools for different jobs.

Conclusion

In this detailed guide, we explored the key differences in Programmable Logic Controller vs Arduino. From their core design philosophies to programming, I/O handling, communication, and cost, each has unique strengths.

For professionals working in the industrial sector, PLCs provide a robust and future-proof automation solution. For students, researchers, and inventors, Arduino offers flexibility and a low-cost entry point into the exciting world of electronics.

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub

#ProgrammableLogicController, #PLCvsArduino, #ArduinoProjects, #IndustrialAutomation, #PLCProgramming, #ArduinoVsPLC, #EmbeddedSystems, #AutomationTechnology, #ControlSystems, #PLCController, #ElectronicsEngineering, #IndustrialElectronics, #AutomationSolutions, #IoTDevices, #SmartManufacturing