GIS vs AIS Switchgear: Best Key Differences Every Electrical Engineer Must Know

Switchgear is a crucial component in power systems, responsible for controlling, protecting, and isolating electrical equipment to ensure uninterrupted power supply. In modern electrical engineering, choosing the right type of switchgear is essential, especially when designing high-voltage substations.

Table of Contents

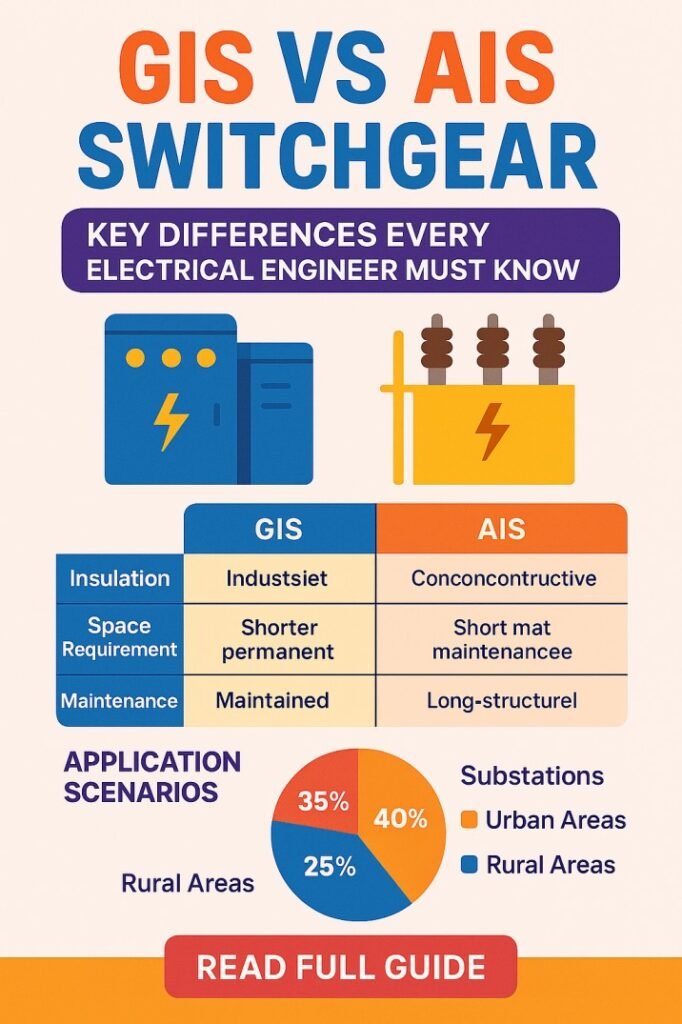

Two of the most widely used types are Gas Insulated Switchgear (GIS) and Air Insulated Switchgear (AIS). Understanding the differences between GIS vs AIS switchgear is vital for engineers, designers, and technicians to make informed decisions. This article delves into the key distinctions, advantages, disadvantages, and practical applications of these two types of switchgear.

Use our online tool for free Sub Panel Breaker Size Calculator – Find the Right Breaker for Your Electrical Sub Panel

What is GIS Switchgear?

Gas Insulated Switchgear (GIS) is a compact type of high-voltage switchgear where all live parts are enclosed in a grounded metal enclosure and insulated with sulfur hexafluoride (SF6) gas. SF6 is a highly effective insulating medium that prevents electrical faults and allows GIS to handle high voltages in a smaller footprint.

The main advantage of GIS is its compact design. This makes it suitable for urban substations or areas where space is limited. GIS is also highly reliable, requires minimal maintenance, and offers superior protection against environmental factors such as dust, humidity, and pollution.

However, GIS tends to be more expensive upfront due to the cost of SF6 gas and complex manufacturing. Despite this, its long-term durability and low maintenance can offset initial costs, especially for high-voltage applications.

What is AIS Switchgear?

Air Insulated Switchgear (AIS), on the other hand, uses air as the primary insulating medium. The live components are separated by air gaps and mounted on open structures or busbars. AIS is the traditional choice for high-voltage switchgear and is widely used in outdoor and indoor substations where space is not a constraint.

AIS is relatively simple in design, making it easier to install, inspect, and maintain. It also comes at a lower initial cost compared to GIS. However, AIS is more sensitive to environmental conditions, such as pollution, humidity, and temperature fluctuations, which may affect reliability over time.

Use our online tool for free Sub Panel Wire Size Calculator – Accurate Wire Gauge & Load Sizing Tool

Because AIS requires larger space to maintain sufficient air insulation, it is less suitable for urban or confined areas. Nevertheless, it remains a popular choice for utilities, industrial plants, and outdoor substations with ample space.

Key Differences Between GIS vs AIS Switchgear

Understanding the differences between GIS vs AIS switchgear helps engineers select the appropriate technology based on project requirements, cost, and space constraints. The main distinctions can be summarized in the following table:

| Feature | GIS Switchgear | AIS Switchgear |

|---|---|---|

| Insulation Medium | SF6 gas | Air |

| Space Requirement | Compact, minimal space | Requires large space |

| Maintenance | Low, sealed enclosure | Moderate to high, requires regular inspection |

| Cost | High initial cost | Lower initial cost |

| Reliability | High, less affected by environment | Moderate, sensitive to dust and humidity |

| Installation Complexity | Complex, requires skilled labor | Simple, easy to install |

| Application | Urban substations, limited space areas | Outdoor substations, industrial plants |

| Environmental Impact | SF6 gas is potent greenhouse gas | Eco-friendly, no greenhouse gas |

| Safety | Enclosed metal structure enhances safety | Exposed components require more precautions |

| Lifespan | Longer, up to 40 years | 25–30 years typically |

Space and Design Considerations

One of the most visible differences between GIS vs AIS switchgear is space. GIS is highly compact due to the superior insulating properties of SF6 gas. For example, a 400 kV GIS substation can occupy only 20–30% of the space required for an equivalent AIS substation. This makes GIS ideal for city substations where land cost and availability are major concerns.

Use our online tool for free Sub Panel Sizing Calculator: Best Tool to Use

AIS, in contrast, needs larger distances between live components to maintain air insulation. These larger air gaps make AIS suitable for outdoor installations or rural substations where space is not an issue. The larger footprint also allows easier access for maintenance and upgrades.

Reliability and Maintenance

Reliability is another critical factor in choosing between GIS vs AIS switchgear. GIS has almost all components sealed in metal enclosures filled with SF6 gas, which prevents moisture ingress, dust accumulation, and corrosion. This ensures long-term stability and reduces the risk of faults. GIS also requires minimal routine maintenance, typically only periodic gas monitoring.

AIS, while simpler, exposes components to environmental factors. Dust, rain, pollution, and temperature fluctuations can affect insulation and performance. Consequently, AIS requires frequent inspection, cleaning, and sometimes replacement of components to maintain reliability.

Use our online tool for free Wire Size Calculator for Subpanels and Feeders – NEC Guidelines Included

Cost Analysis

Cost is always a major consideration in substation design. GIS involves higher initial investment due to complex manufacturing, gas insulation, and sealed enclosures. Transportation and installation also require specialized equipment and skilled personnel.

AIS is cheaper upfront, with simpler installation and fewer specialized requirements. However, over time, maintenance costs may increase, especially in harsh environments. For long-term, space-constrained projects, GIS may offer better cost-effectiveness despite higher initial costs.

Safety and Environmental Considerations

Safety is a significant concern in high-voltage installations. GIS provides better safety due to its fully enclosed design. Operators and maintenance personnel are less exposed to live components. AIS, with exposed live parts, requires strict safety protocols, barriers, and protective equipment during maintenance.

From an environmental perspective, SF6 gas used in GIS is a potent greenhouse gas if leaked. Proper handling, recycling, and leakage prevention are essential to minimize environmental impact. AIS uses air as an insulating medium, making it environmentally friendly and free from greenhouse gas concerns.

Know more about Industrial Control Panel Design Software – Best Tools, Features & Pro Tips for Engineers

Typical Applications

The choice between GIS vs AIS switchgear depends heavily on application requirements.

- GIS Switchgear Applications: Urban substations, airports, underground substations, industrial plants with space constraints, high-voltage installations above 245 kV.

- AIS Switchgear Applications: Rural and outdoor substations, industrial plants with ample space, medium-voltage substations, areas with lower installation budget constraints.

Performance Comparison

| Parameter | GIS Switchgear | AIS Switchgear |

|---|---|---|

| Voltage Rating | Up to 800 kV | Up to 765 kV (common), larger air gaps for higher voltages |

| Short Circuit Rating | High | Moderate to high |

| Fault Handling | Excellent due to sealed environment | Good but requires more safety margin |

| Temperature Stability | Stable in all climates | Sensitive to extreme humidity and pollution |

| Life Expectancy | 35–40 years | 25–30 years |

Use our online tool for free Electrical Panel Upgrade Cost Calculator: Best Tool

Conclusion

Choosing between GIS vs AIS switchgear requires careful consideration of multiple factors, including space, cost, reliability, maintenance, safety, and environmental impact. GIS is ideal for high-voltage, space-constrained, and high-reliability applications, offering compactness and low maintenance but at a higher initial cost. AIS is suitable for outdoor or rural substations, offering simpler installation and lower upfront costs but requires more space and maintenance.

Electrical engineers must evaluate project-specific conditions and long-term operational needs before selecting the appropriate switchgear. Understanding the nuances between GIS vs AIS switchgear ensures optimal performance, safety, and cost-efficiency in modern power systems.

Know more about mcc panel design software

Follow Us on Social:

Subscribe our Newsletter on Electrical Insights for latest updates from Electrical Engineering Hub